Introduction:

A diesel particulate filter (DPF) is a crucial part of the exhaust aftertreatment systems of modern diesel engines. Its primary function is to filter soot particles (particulate matter) from the exhaust gases, thus reducing the emission of harmful substances. Soot particles are formed during the combustion process, especially during incomplete combustion, and can be harmful to both health and the environment. Since the implementation of stricter emission regulations, DPFs have become standard on new diesel vehicles to meet Euro 5 and Euro 6 standards.

By capturing the soot particles in the filter and regenerating it regularly, the emission of particulate matter is drastically reduced. This makes DPFs indispensable in the pursuit of cleaner air and compliance with environmental regulations.

Formation of Soot Particles:

Soot particles always form during the combustion process of a diesel engine. Soot is an indication of incomplete combustion. Soot particles are small carbon spheres with a core of pure carbon, measuring about 0.05 micrometers in diameter. Certain harmful substances, including hydrocarbons, sulfur, and metal oxides, adhere to this carbon core. Some hydrocarbons can be harmful to health.

The formation and quantity of soot particles depend mainly on usage, air supply, injection, and the combustion process of the engine. Especially when there is an oxygen deficiency, soot emissions increase because the mixture is too rich, resulting in incomplete combustion. Chip tuning can also cause excessive soot emissions.

The size of the soot particles is almost the same for both indirect-injected diesel engines with a swirl chamber, direct-injected, common-rail, and pump-injector engines.

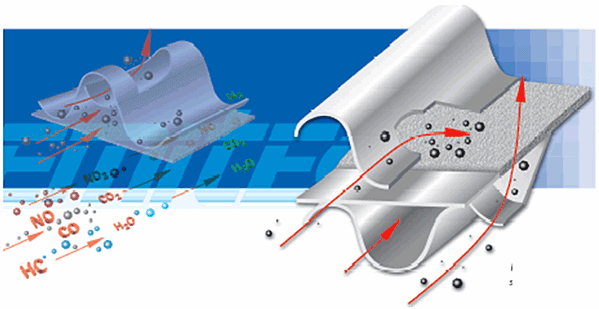

Operation of a Diesel Particulate Filter:

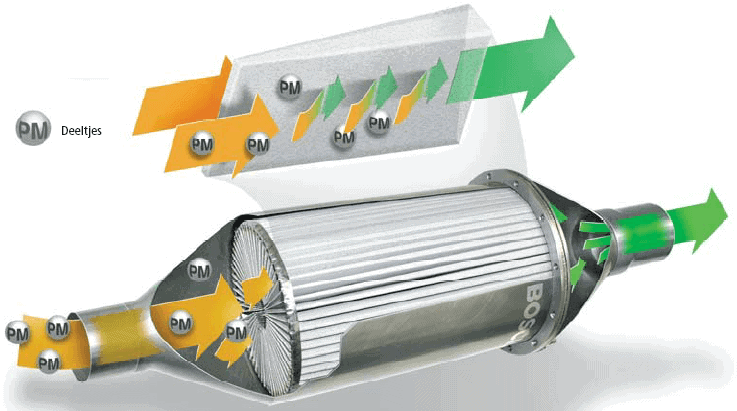

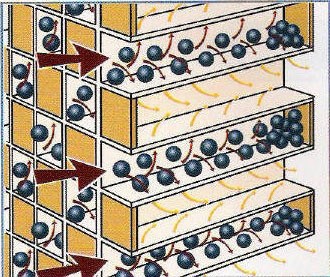

The DPF consists of a honeycomb-shaped ceramic body made of silicon carbide that is housed in a metal casing. The ceramic body contains many parallel, microscopically small channels, which are alternately closed off at one end.

When exhaust gases pass through the DPF, the particles are trapped in the inlet channels, while other gaseous components of the exhaust gas pass through the porous walls of the filter.

Regeneration of the Diesel Particulate Filter:

After some time, a large number of soot particles accumulate in the self-regenerating DPF, which would otherwise clog it without intervention. To prevent this, the filter must be regenerated regularly (every 200-1000 km). This process is called “regeneration.” This means the accumulated soot particles are burned. During combustion, the particles are converted into the harmless substances carbon dioxide and water. The combustion temperature of the soot particles for non-catalytic coated DPFs is at least 600ºC, but the exhaust gases are often not hot enough to reach this. The following methods can be applied to burn the soot particles:

Diesel Particulate Filter with Catalytic Coating:

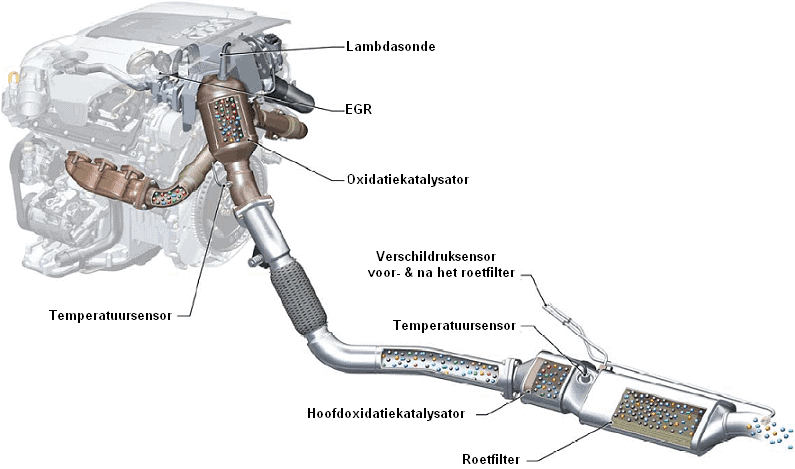

A DPF with a catalytic coating is designed to remove soot particles (particulate matter) from diesel engine exhaust gases. Due to the catalytic layer, the accumulated soot particles can burn at a relatively low temperature of about 250°C. To minimize heat loss, this type of DPF is placed as close to the engine as possible, usually directly after the exhaust manifold.Oxidation Catalyst:

An oxidation catalyst is often placed before the DPF. This catalyst converts some of the nitrogen oxides (NO) in the exhaust gases into nitrogen dioxide (NO₂). NO₂ is a potent oxidizing gas and more readily reacts with soot, allowing the soot to burn at a lower temperature. This supports the regeneration of the DPF. In some systems, even two oxidation catalysts are used to enhance this effect.External Heating:

When the exhaust gas temperature is insufficient to initiate regeneration, external heating can be applied. This can be done with a heating coil or a fuel injector in the exhaust system, which generates additional heat. The engine control unit (ECU) continuously monitors the signals from the differential pressure sensors before and after the DPF. When these sensors indicate that the backpressure is rising — suggesting a filling filter — external heating is activated to start regeneration.Extra Fuel Injection:

An alternative method to raise the temperature in the exhaust system is additional fuel injection during the exhaust stroke. The unburned fuel burns further along in the exhaust system, increasing the exhaust gas temperature. This brings the soot in the filter to ignition and allows the filter to regenerate.

Retrofit Diesel Particulate Filter:

DPFs are available for vehicles that were not originally equipped with a DPF from the factory. Therefore, they are retrofitted. Nowadays, they are becoming less common because all modern diesel cars come standard with a fully closed DPF.

This type of DPF has a partially open structure, allowing exhaust gases to flow relatively freely through the filter, minimizing backpressure in the exhaust system. Soot particles settle on the filter walls, where a catalytic coating (usually platinum or cerium oxide) enables the combustion of soot at 250–300°C. The coating converts nitrogen oxides (NO) into nitrogen dioxide (NO₂), which allows the soot to burn more easily, even at lower temperatures achieved during normal operation. This ensures continuous regeneration as long as the engine is sufficiently loaded and the exhaust gases are at the right temperature.

A significant advantage is that the filter rarely clogs, provided the vehicle is regularly driven to a high temperature.

While under ideal conditions the filter can reduce soot emissions by 50–60%, the effectiveness in less optimal conditions (such as urban traffic) is often only 20–40%, depending on the driving profile and engine temperature.

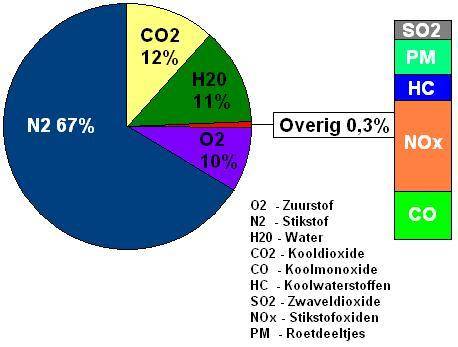

Exhaust Gases of a Diesel Engine:

The adjacent image and the explanation below show the composition of exhaust gases from a diesel engine.

- 67% Nitrogen (N2)

- 12% Carbon Dioxide (CO2)

- 11% Water (H2O)

- 10% Oxygen

- 0.3% other substances, including soot particles (PM), Hydrocarbons (HC), Nitrogen Oxides (NOx), Carbon Monoxide (CO).

To reduce NOx emissions, diesel engines increasingly use a SCR catalyst with an AdBlue dosing system.