History of the diesel engine:

The diesel engine is named after its inventor Rudolf Diesel (1858-1913). The first diesel engine based on Diesel’s theory became reality on February 17, 1894. This engine operated on the principle of compression ignition and ran for 1 minute at 88 rpm. Robert Bosch developed the high-pressure injection pump that enabled the diesel engine to begin its worldwide conquest.

The first passenger car with a diesel engine was the Mercedes-Benz 170D from 1935.

Operation:

A diesel engine draws in air into its cylinders. Unlike gasoline engines, there is no mixture of air and fuel. In a diesel engine, air is sometimes drawn in by the engine itself (without a turbo) or usually supplied under pressure by a turbocharger. This is known as forced induction. Forced induction results in a larger volume of air, which can be ignited with additional fuel. For more information on forced induction, see the turbo page. The diesel engine is supplied with as much air as possible, which is not regulated by volume as in gasoline engines. This unlimited air supply is referred to as “air surplus.”

Fuel in the diesel engine is not ignited with the assistance of a component (like a spark plug ignites gasoline fuel in a gasoline engine). In a diesel engine, combustion is initiated by injecting diesel fuel. This is why a diesel engine is called a “compression ignition engine.” The high-pressure fuel pump provides the necessary fuel pressure.

A lot of heat is required for this combustion. This heat is generated by the high compression pressure created by the piston during compression. By compressing the air (subject to very high pressure), a significant amount of heat is generated. This heat is essential for combustion.

The injector injects a specific amount of diesel fuel just before the piston reaches TDC. This usually occurs in several steps, including pre-, main-, and post-injection. When diesel fuel mixes with the compressed hot air (due to high end-compression pressure), it ignites on its own. This is called the power stroke. (More on the four-stroke process later).

The diesel engine needs heat to start combustion. This heat (of at least 250 degrees) is not yet present when the engine is started. Often, the end-compression pressure does not provide the right temperature in the combustion chamber. To address this, glow plugs are installed in the cylinder head. These glow plugs activate when the engine is started, ensuring that the air in the combustion chamber reaches the right temperature for the diesel fuel to ignite.

Advantages & Disadvantages of the diesel engine

- Advantages of a diesel engine compared to a gasoline engine:

Due to the higher compression ratio and combustion process, a diesel engine is more fuel-efficient than a gasoline engine. Generally, a diesel engine also has a longer lifespan (depending on usage). - Disadvantages of a diesel engine compared to a gasoline engine:

A diesel engine is noisier, has lower power compared to a gasoline engine with the same cylinder capacity (without using a turbo and intercooler), and is a more expensive and heavier-built engine. Preheating the engine is no longer a disadvantage since a directly injected diesel engine can start without preheating. Even at freezing temperatures, it will start after a slightly longer cranking.

Modern diesel engines are becoming quieter, making it increasingly difficult to distinguish between gasoline and diesel engines.

Work cycle of the four-stroke diesel engine:

The work cycle of a diesel engine comprises four strokes; intake stroke, compression stroke, power stroke, and exhaust stroke. During these strokes, the piston moves down and up twice. Consequently, the crankshaft rotates twice.

Each stroke involves different processes: air intake, fuel injection, combustion of air and fuel, and expelling of residual gases. Below is a description of what occurs in each stroke:

- Intake stroke:

The intake valve is open, and the exhaust valve is closed. The piston moves from TDC to BDC.

– Without a turbo: Air is drawn in due to the vacuum created.

– With a turbo: Intake air is delivered into the combustion chamber under pressure from the turbo.No regulating valve like the throttle of a gasoline engine is present in the intake path. Thus, the quantity of air being drawn in by a diesel engine is not regulated. The throttle valve, present in the intake system (throttle valve), is only for turning off the engine. By closing this valve and halting air intake, the engine will shut down smoothly.

Compression stroke:

The intake and exhaust valves are closed. The piston moves from BDC to TDC. The air is compressed, raising its temperature. Depending on the compression ratio, the temperature can reach around 550 degrees. The temperature in a gasoline engine is about 400 degrees. During a cold start, the engine is preheated by the glow plugs to achieve the temperature necessary for the mixture to ignite.Power stroke:

The intake and exhaust valves are closed, and the piston has compressed the air under very high pressure. A few degrees before TDC, fuel is injected by the injector, igniting due to the high end-compression pressure. The pressure from combustion forces the piston from TDC to BDC.Exhaust stroke:

The intake valve is closed, the exhaust valve is open. The piston moves from BDC to TDC, expelling the exhaust gas. The cycle process is described on the Seiliger process page.

Direct & Indirect injection:

An engine can be configured with either direct or indirect injection. Below are the differences between the two systems.

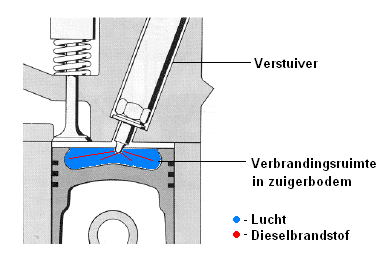

Direct injection:

The injection pressure is higher in direct injection than in indirect injection. Fuel is sprayed directly into the cylinder (or specially formed piston bowl) at the end of the compression stroke. Mixing occurs inside the cylinder, not in the swirl chamber, as with indirect injection. To improve mixing, the intake air is swirled. This swirling is achieved by the shape of the intake manifold and the piston bowl.

A diesel engine with direct injection, compared to one with indirect injection, has the advantage of needing less surface area of the combustion chamber, resulting in less loss of compression and combustion heat and achieving higher efficiency and cleaner exhaust emissions.

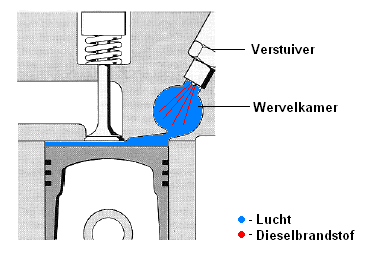

Indirect injection:

Indirect injection was predominantly used in older diesel engines and is nearly obsolete today.

In an engine with indirect injection, fuel is not injected above the piston but injected, mixed, and evaporated in the swirl chamber. The fuel is injected during the compression stroke into the swirling air of the swirl chamber. This method provides good mixing of fuel and air. In this case, the piston bowl is flat (sometimes with cutouts for the valves).

Low & high-pressure system:

The fuel delivery system of a diesel engine is divided into two parts; the low-pressure section and the high-pressure section.

The low-pressure section consists of the following components:

- Fuel tank

- Lift pump (mounted in the fuel tank or as a complete unit with the high-pressure pump)

- Fuel filter (mounted under the car or under the hood, removing contaminants and moisture from diesel fuel)

- Low-pressure fuel lines (fuel is transported from the tank to the high-pressure pump via these lines)

- Fuel return line (returns excess and leak fuel from the injectors, high-pressure pump, and filter back to the tank). This return/leak fuel is necessary for cooling and lubrication of the relevant components. Heat is thus transferred to the tank.

The high-pressure section consists of the following components:

- High-pressure fuel lines (fuel is transported from the high-pressure pump to the injectors via these lines. All lines must be of equal length and thickness to prevent pressure differences)

- High-pressure pump (fuel sent from the lift pump to the high-pressure pump is then pumped through the high-pressure fuel lines to the injectors)

- Injector (injects fuel into the cylinder upon reaching opening pressure)

Injection process:

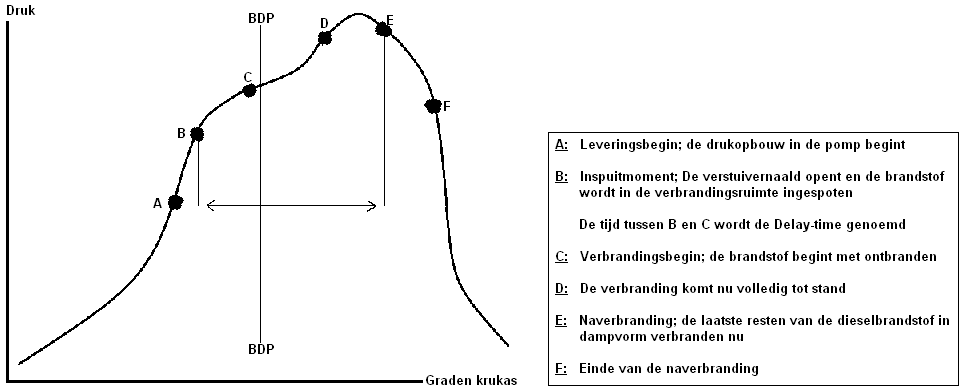

The time between fuel injection and actual combustion is known as delay-time. Tiny fuel droplets sprayed by the injector must vaporize. This transition is possible due to the high temperature within the combustion chamber (achieved by compression end pressure or by glow plugs during starting). This time must be as short as possible; otherwise, it affects combustion. This also means the engine performs poorly and offers less power.

The complete injection process is illustrated in the image below.

Diesel knock:

A few milliseconds lie between the injection start (see A in the above image) and the combustion start (C). Tiny fuel droplets injected by the injector (the fuel mist) must first be brought to temperature to transition into vapor form. The outer part of the fuel droplet first vaporizes and then gradually combusts. The remaining parts of the droplet then ignites spontaneously, causing the recognizable engine sound; diesel knock. This is uncontrollable combustion and can occur at the wrong time.

The following factors can cause diesel knock:

- Defective injectors (dripping or poor atomization with overly large droplets)

- Defective injection pump (leaking valve or defective plungers)

- Fuel (presence of water, low cetane number, air in fuel)

- Engine (low compression end pressure, non-working glow plugs)

- Incorrect timing of the fuel pump’s distribution