Introduction:

The first concept of the CVT principle was designed as early as 1490 by Leonardo da Vinci.

In the 1950s, these transmissions were used in popular DAF passenger cars (under the name Variomatic). These cars could drive equally fast forward and backward.

Nowadays, the CVT principle is still widely used. Certain car brands; Audi and Seat with the multitronic, Nissan, Toyota, Ford, Fiat, Suzuki, Subaru, Rover, Mini (BMW group), Dodge, Jeep, Mitsubishi, Saturn (and perhaps another manufacturer) use or have used a CVT transmission in certain models.

CVT is applied not only in cars but also in karts, snowmobiles, scooters, and certain ATVs.

Operation of the CVT:

CVT stands for Continuously Variable Transmission. This means that the gear ratios constantly change. In manual, automatic, and DSG transmissions, each gear has its own gear ratio. This gear ratio is determined by the number of teeth on the gears on the shafts (in the manual transmission) and the gear ratio of the planetary gear system (in the automatic transmission).

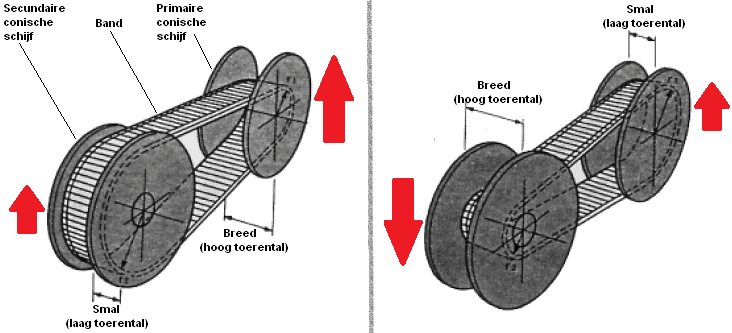

In a CVT transmission, there are no fixed gear ratios. It is not the gears that provide the transmission, but a rubber or metal push belt that moves over pulleys that vary in thickness. The change in diameter of the pulleys results in a different gear ratio. Because the pulleys adjust continuously, changing smoothly in size, no shift shocks occur as they do in a conventional transmission.

The operation is illustrated in the image. However, the pulleys vary in one motion from neutral to small to large here. In reality, this change is gradual.

Seamless Acceleration:

The primary conical pulley is driven by the engine (crankshaft) and the secondary conical pulley is connected to the differential and the car’s drive shafts. At low speeds, the primary pulley is wide and the secondary pulley is narrow (see the image below). High engine speed and low speed enable high engine torque to the wheels for taking off. As speed increases, the primary pulley changes from wide to narrow and the secondary pulley from narrow to wide. During this transition, the engine speed remains constant while the vehicle speed increases.

Acceleration in Different Stages:

Often, a CVT transmission also allows selecting different stages. This can be done, for example, by putting the gear lever in the S position (Sport) or on Manual.

In Manual selection, just like in conventional Automatic transmissions, programs 1 (high engine speed at low speed) through 3 (low engine speed at high speed) can be chosen. Or it can be manually shifted between the 1st through the 6th gear.

When manually engaging, for instance, the 2nd gear (2nd stage), the transmission behaves the same as a normal automatic gearbox. This is not due to a construction in the gearbox but because the primary and secondary pulleys assume a certain position. For each stage, the transmission’s electronics have recorded a certain width of the pulleys in memory. Because the width between the pulleys does not vary, the engine, for example, remains at 3000 rpm at a speed of 60 km/h.

This function can be used when driving with a trailer, or before the driver wants to make an overtaking maneuver. By selecting a certain stage where the engine operates around the torque area, acceleration can be initiated more easily. In D (drive) mode, the engine speed automatically drops back to around 1500 rpm. When the gas pedal is pressed (the kickdown), the pulleys must first assume a different position, which takes time. The Sport and Manual modes prevent this issue.

Planetary Gear System:

A single planetary gear system is also connected to the primary pulley, which is also part of a conventional automatic gearbox. This planetary gear system enables the reverse gear to be engaged.

More information about this can be found on the automatic transmission page. (The operation here is the same and not really relevant on this page).

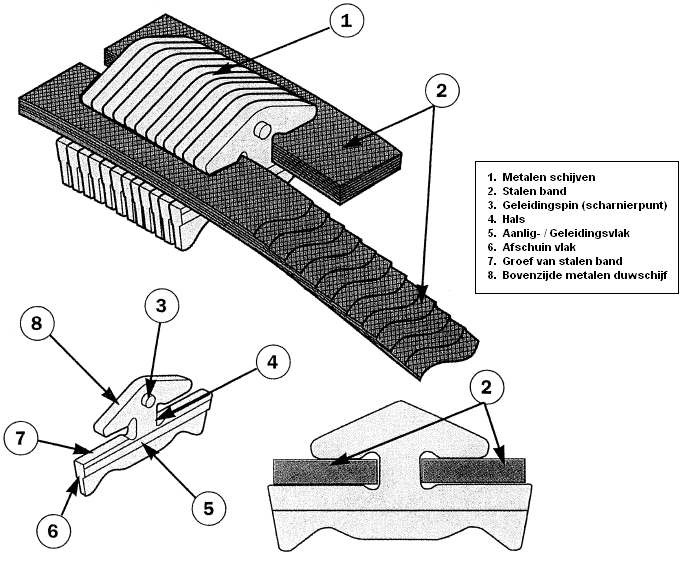

Push Belt:

The push belt in passenger cars is designed as shown in the image below. The steel belt is essentially a ring, with lots of metal plates clamped around it. The guide pins allow the metal plates to pivot relative to one another, enabling a variation in diameter by allowing the movable pulleys to become wider or narrower.

Since the metal plates are all pressed tightly together, large pushing forces can be transmitted. The angle at which the metal plates are placed can be small when the pulley assumes a small diameter.

Variable Pulleys:

The control of the pulleys’ diameters is determined by the ECU (the engine management system). The engine management receives information from sensors, which determines the position and changes the gear ratio. The following information is important for the ECU:

- Engine speed

- Vehicle speed

- Throttle position

- Position of the selector lever (shifter)

- Position of the planetary system

- Driving resistance

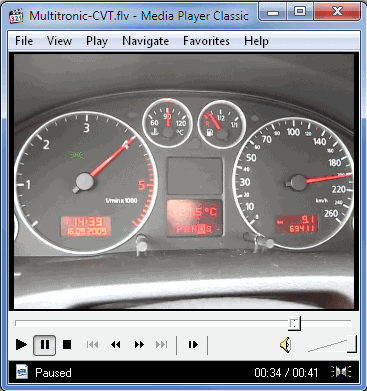

Video of the Instrument Panel during Acceleration:

Below is a video of an Audi A4 with a Multitronic gearbox. This also operates according to the CVT principle. This video provides a good impression of how this transmission works and how it is experienced by the driver. This Audi driver fully presses the gas pedal. With more moderate acceleration, the engine speed also remains the same while speed increases, but then for example at 2000 rpm.

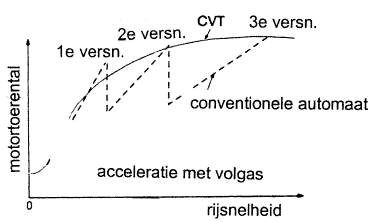

Graph:

As seen in the video above, the engine speed remains constant during acceleration. This is also shown in the graph below. A conventional automatic shifts up several times, leading to speed peaks. The CVT features a linear line without peaks. The advantage here is that the engine is optimally loaded in the most favorable torque area.