Introduction:

The mass forces in an engine create vibrations. The more cylinders an engine has, the fewer vibrations will occur. This is because in a 3-cylinder engine a power stroke occurs every 240 degrees, in a 4-cylinder engine every 180 degrees of the crankshaft, in a 6-cylinder every 120 degrees, in an 8-cylinder every 90 degrees, and in a 12-cylinder every 60 degrees. So, if an engine has more cylinders, there are more power strokes in a short time and the engine is almost vibration-free. Most passenger cars use 4-cylinder engines. In these engines, many vibrations occur that are transmitted to the interior. The counterweights on the crankshaft primarily reduce engine vibrations.

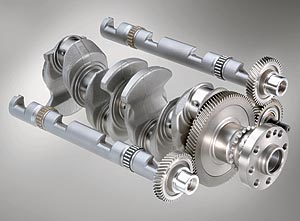

To further limit engine vibrations, constructors from several car brands have applied the “balance shaft” principle. Each brand has its own construction (a single balance shaft, 2 balance shafts at the same height, 2 balance shafts where one is low and one higher in the block, etc.). The balance shaft drive is accomplished via the timing (gears, belt, or chain) and must be “timed” during maintenance. A balance shaft that is not timed will amplify engine vibrations even more, leading to component failures.

Operation of Balance Shaft:

The balance shaft is a shaft that is itself unbalanced and thus compensates for the mass forces primarily caused by the secondary piston motion. Along its entire length, there are thickenings, cams, or deformations that cause the required imbalance during rotation. Both primary forces (the up-and-down piston movement) and secondary forces (the lateral forces due to the connecting rod being pushed down at an angle) are absorbed by the balance shafts. To achieve this, the balance shafts rotate at twice the speed of the crankshaft. When there are two balance shafts in the engine, they rotate in opposite directions.

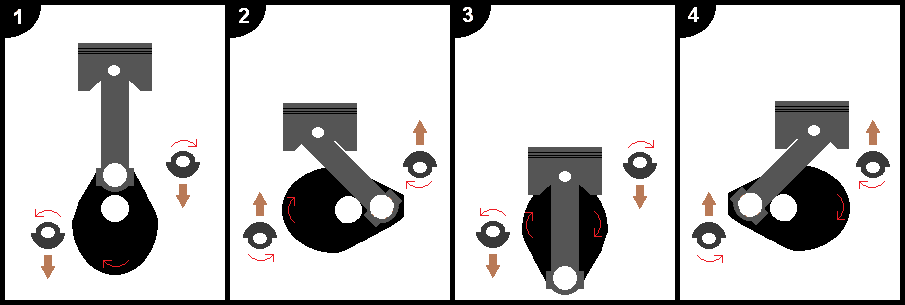

1: The piston is at TDC. The balance shafts are directed downwards. The lower balance shaft rotates counterclockwise, and the upper balance shaft rotates clockwise. The balance shafts both rotate twice as fast as the crankshaft.

2: The crankshaft rotates 45 degrees and the piston moves from TDC to BDC. In this position, the mass forces caused by the secondary piston motion are greatest. During the secondary piston motion, mass forces are directed downwards. To compensate for this, the balance shafts in this position are directed upwards.

3: The crankshaft rotates another 45 degrees and is at BDC. The balance shafts are directed downwards.

4: The crankshaft moves from BDC to TDC. After 45 crankshaft degrees, the balance shafts are directed upwards again. Once more, the greatest (downward directed) mass forces originating from the secondary piston motion occur in this position. The upward-directed balance shafts compensate for these mass forces.

Related pages: