Air cooling vs. liquid cooling:

In liquid-cooled engines, there are cooling channels in the engine block and cylinder head through which coolant flows. The coolant does not actually cool, but absorbs the heat from the components and carries this heat to the radiator. The coolant is then cooled by the airflow. Afterwards, the cooled coolant flows again past the warm engine parts to absorb heat.

Advantages of liquid cooling over air cooling:

- Consistent cooling. The flow of the coolant can be controlled precisely. The heat discharge can be better managed, resulting in smaller temperature differences. Coolant rapidly absorbs heat, can store a lot of it, and is quite thin, allowing it to be pumped quickly through the cooling system.

- Less engine noise. The fluid around the cylinders dampens noise.

- When the engine is turned off after a long drive, it stays at temperature longer (advantageous during breaks, as the engine is less cold after restarting). The coolant slows down the cooling process of the engine. As the engine cools slowly, fewer material stresses occur than when some engine parts cool faster than others.

Types of coolant:

Coolant comes in several types and colors:

- Green or blue (G11). Contains silicates (salts) and can be used in older engines. It is most commonly used, for example in BMW and most MINI models.

- Red / Yellow (G12). This coolant is suitable for aluminum engines and the silicates have been replaced with Organic Acid Technology (OAT). Yellow coolant can be found in, among others, Renault;

- Purple / colorless (G12+). This universal coolant contains improved additives compared to red or yellow coolant;

- Red / Pink (G12++, G13). Contains silicate additives and offers extra aluminum protection in modern engines, is suitable for longlife applications and is mainly used by Volkswagen / Audi etc.

Before topping off coolant, one must first check which type (color) is required. Adding or mixing the wrong type of coolant can be harmful to the engine components.

Coolant components:

Coolant consists of a mixture of demineralized water, antifreeze (glycol), and additives. These additives protect the engine components and parts of the cooling system and are referred to as “additives”.

- Water: lime and chlorine have been removed from the demineralized water to prevent blockages and damage to engine components.9

- Antifreeze: antifreeze (glycol) is added to coolant to lower the freezing point. Without antifreeze, the coolant would freeze at 0b0C, potentially damaging engine components (cracks) due to the expansion of frozen water. Adding antifreeze lowers the freezing point between -25 b0C and -40 b0C. Mono Ethylene Glycol (MEG) or Mono Propylene Glycol (MPG) can be used, with MEG having a greater heat absorption capacity and therefore being more commonly used, while MPG is less harmful to the environment. The mix ratio between water and antifreeze determines the freezing point.a0

– A mix of 30:70 (30% antifreeze and 70% water) is often sufficient in moderate climates;

– In climates where temperatures frequently drop well below freezing, the mixtures are adjusted to 60:40 or 70:30. - Additives: the additives in coolant are called additives. They enhance the properties of the coolant:

– Antifoam additive: when coolant foams, it absorbs less heat, obstructing circulation. Foaming can also cause cavitation. Cavitation occurs when air bubbles implode suddenly due to pressure changes. The pressure waves can even break pieces from metal components;

– Anti-sludge additive: clumping of components can lead to blockages;

– Anti-corrosion additives: since engine parts and coolant consist of various metals, electrolytic corrosion can occur.

The anti-corrosion additive prevents this corrosion by inhibiting conduction;

– Lubrication: adding a lubricant prevents wear on the coolant pump seal. Without a lubricant, more friction occurs between the shaft and the seal, potentially causing squeaking noises and faster wear and leaking of the seal.

Determining antifreeze content:

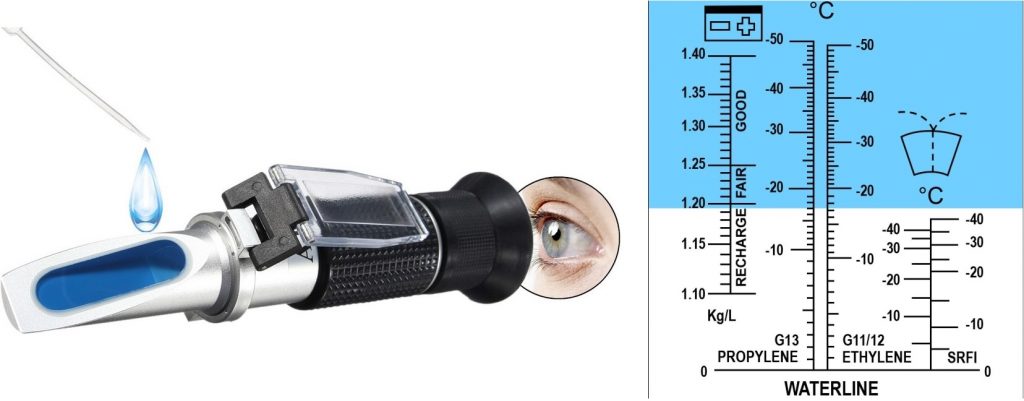

During a (major) car maintenance, the antifreeze content of the coolant is checked. Over time, the antifreeze amount may decrease, e.g., after topping it up with water. The antifreeze content can be checked in two ways:

- A refractometer can measure the refraction of light through liquids, also known as an optical meter. The higher the antifreeze content, the more slowly light passes through, with a stronger bending effect on the light. By applying a few drops of coolant on the glass, the refractive breakpoint can be observed through the viewfinder against the light. The dividing line between white and blue (see the image below) indicates the temperature down to which the coolant provides protection. In the example, it is -28 b0C. Measuring tap water without additives will show a separation dropping to 0 b0C;

- The antifreeze tester measures the specific gravity of the coolant. Antifreeze has a higher specific gravity than water. The mix ratio affects the weight. The higher the weight, the more antifreeze is present.

If it is found that the antifreeze content is too low, the coolant should be replaced. Adding pure antifreeze to the existing coolant is not recommended. The next paragraph explains why it is better to replace the coolant.

Coolant replacement interval:

Coolant is often not replaced periodically, unlike motor oil. Manufacturers usually do not specify a replacement interval. Still, it is advisable to replace the coolant every few years. Over time, the additives deplete and no longer protect against foaming, sludge, corrosion, or provide lubrication. When corrosion occurs in the engine block, metals dissolve slightly in the water. Differences in the tendency to dissolve create a battery effect. An electrical voltage forms between different metals, potentially creating a circuit where one metal corrodes. If the coolant also contains salts or acids, as when tap water is used, conductivity increases.

Aside from the increased risk of corrosion, pollution also increases. Via sweating gaskets, wear of the water pump, and tiny metal particles due to erosion from the fluid flow, the coolant gets contaminated, leading to more wear.

It is advisable to replace the coolant every two years, or at most every four years and a maximum of 50,000 km. After repairs to, for example, the radiator, coolant pump, or thermostat, it’s better not to reuse the drained coolant. Filling with new coolant is preferred.

The images below show coolant where the additives have depleted, and likely dilution with tap water has occurred. The coolant turns brown, coloring all parts and channels in the cooling system. This “rust water” can be flushed out, after which the system can be refilled with new coolant. If not done in time, defects such as water pump leakage, leaking seals and gaskets, clogged (heater) radiator, faulty thermostat, and deposits on the cooling system walls can occur.

Replacing coolant:

There is often a drain plug at the bottom of the radiator. If not, the lower radiator hose can be pulled to drain most of the cooling system. Some engines also have drain plugs on the engine block itself. Consult the instruction manual in advance to locate the drain plugs.

After draining, the system can be filled. While bleeding one car is very easy, for another, one or more bleed screws must be partially opened to release the remaining air through the highest point of the system. Some engines are so difficult to bleed that the car must be tilted backwards with the engine running to release the air bubbles through the highest point (the radiator cap or expansion tank).

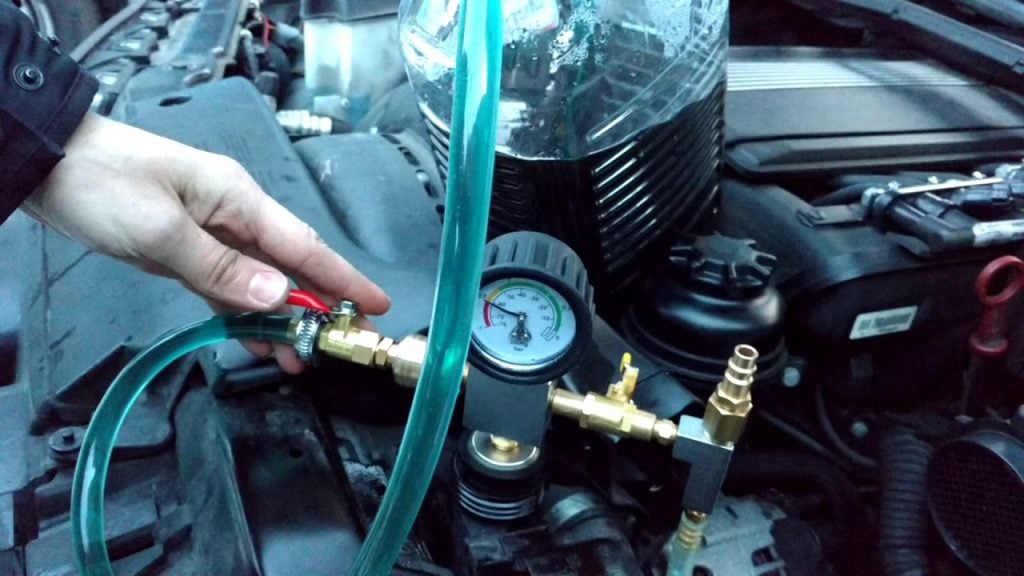

The best way to fill the cooling system is to first vacuum it. Using a cap with valves and compressed air, the entire cooling system can be vacuumed. By then opening the valve of the coolant container, the new coolant is drawn into the system. In this case, there’s no need to bleed.

Once the system is filled and bled, a fairly simple way to check if the circulation is correct is to ensure a clear return flow is visible in the expansion reservoir. The heater should also be sufficiently warm. Is the engine at operating temperature but the heater is not warming up or only slightly? Or does the temperature increase with acceleration, but the air becomes cooler again afterward? Then there are still air bubbles in the system.

Latest generation coolant:

The conventional anti-corrosion additives are insufficient to adequately protect combinations of different materials. Rapid erosion occurs on the water pump, and the cooling channels become blocked as the coolant turns into a gel. Additionally, plastics can harden and fracture. To prevent this, the latest generation of coolants are equipped with additives made from organic carboxylic acids, which do not form a protective layer over metals and thus do not damage the metal.