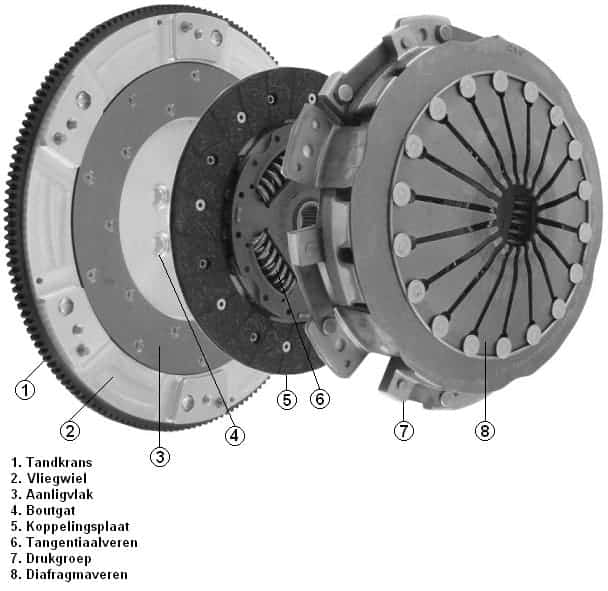

Clutch and Pressure Plate:

The purpose of the clutch is to engage and disengage the engine from the driven wheels at the desired moment. The clutch consists of a clutch disc and a pressure plate (see image below). These are attached to the engine’s flywheel. In the resting position, the pressure plate clamps the clutch disc against the flywheel. The lining of the clutch disc (5) then clamps against the contact surface (3) of the flywheel.

When the clutch pedal is pressed, the throw-out bearing pushes against the diaphragm springs of the pressure plate. This occurs on the inside of the diaphragm springs. Through diaphragm action, the outside of the pressure plate flexes outward. The clutch is “disengaged.” When the clutch pedal is released, the throw-out bearing exerts less force on the diaphragm springs. These springs return to the neutral position, causing the outside of the diaphragm to move back towards the clutch disc. The clutch is once again enclosed between the pressure plate and the flywheel. By doing this very gradually and allowing the clutch to slip between the flywheel and the pressure plate, the car starts moving. If this position is held too long, or if done at too high an engine speed, the lining of the clutch disc will wear faster or even get damaged.

The clutch disc is a wear part. The characteristics of the wear are described at the bottom of this page. In 99% of cars, the transmission must be removed when replacing the clutch. This is a lot of work in most cars. Sometimes the subframe also has to be removed. In some cases, it is even advisable to remove the entire engine block with the transmission as a single unit.

When replacing a clutch disc, it is customary to also replace the pressure plate and throw-out bearing. It is unwise to leave them in place because the pressure plate is also subject to wear, such as the flexing of the diaphragm springs and the contact face on the back of the pressure plate where the clutch disc is pressed against.

Never apply too much grease on the input shaft or other parts of the clutch. Some manufacturers even prohibit the use of grease! There is quickly too much grease, on which dust from the clutch lining will quickly stick.

After disassembly, clean everything thoroughly and make it grease-free. This is more important than applying grease. If you still want to apply some, a very thin layer should be applied to the spline of the input shaft. So minimal that it is almost not visible.

Throw-out Bearing:

The throw-out bearing is mounted with springs on the inside of the transmission housing and slides along the splines of the input shaft. On one side of the throw-out bearing is the lever, and on the other side are the diaphragm springs of the pressure plate. When the engine is running, the pressure plate with the diaphragm springs rotates at the same speed. The crankshaft directly drives the flywheel and thus also the clutch. The lever does not rotate. It only makes a back-and-forth movement when the clutch pedal is pressed or released. The throw-out bearing allows the “stationary” lever to press the rotating diaphragm springs. There are ball bearings between the two parts of the throw-out bearing, allowing these parts to move relative to each other.

The depicted throw-out bearing is a thrust bearing, which is described on the page bearings.

Mechanically Operated Clutch System:

In the mechanical operating system, Bowden cables are used. Rods used to be utilized, but due to too many disadvantages, such as reaction forces strongly transmitted to the clutch pedal and the play that develops over time at the hinge points, they are no longer applied. We will not elaborate further on this here. A Bowden cable does not have these disadvantages. However, its disadvantages are that over time, the cable stretches, necessitating adjustment. Moreover, with aging and due to dirt and moisture, the cable will become increasingly heavy.

Operation: When the clutch pedal is pressed, the hinged motion above the pedal pulls the inner cable in the Bowden cable. This causes the clutch lever to pivot around the hinge point (a fixed point in the transmission housing), pressing the throw-out bearing inward. The throw-out bearing pushes against the diaphragm springs of the pressure plate, freeing the clutch disc. The clutch is then disengaged.

The cable can often be adjusted. Sometimes the cable has a self-adjusting mechanism. With aging, the cable may become heavy or start to creak. Lubricating the cable can sometimes help. This can be done by letting a little lubricant flow into an opening of the Bowden cable and operating the cable frequently. However, the best solution is to replace the cable.

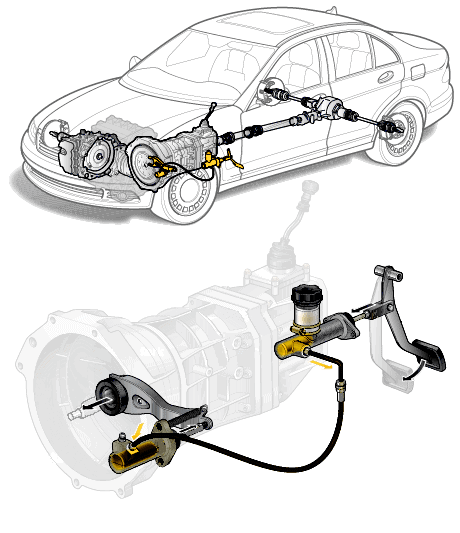

Hydraulically Operated Clutch System:

In the hydraulic clutch system, the force from the brake pedal is exerted on the pressure plate using fluid (usually brake fluid). The main advantage is that the clutch can be operated more smoothly than with the mechanical system using a clutch cable. Since brake fluid is used, the circuit is linked with the braking system. Thanks to a special flow valve, even if the clutch system leaks, the brake system will never be left without fluid. When bleeding the brake fluid of the brake system, the clutch fluid can also be refreshed simultaneously by opening the nipple on the clutch cylinder on the transmission.

Operation: When the clutch pedal is pressed, fluid pressure is built up in the clutch cylinder behind the brake pedal (the master cylinder). This fluid pressure is transferred via a hose to the clutch cylinder at the transmission housing (also known as the slave or working cylinder). The piston of this working cylinder presses against the bottom of the lever. As the upper part is mounted against a fixed point of the transmission housing, the middle part will move to the left. In the middle part, the throw-out bearing is mounted, which will depress the diaphragm springs during operation. Just like with the diaphragm springs of a mechanically operated system, the clutch disc will be freed upon actuation.

When the clutch pedal is released, the diaphragm spring will push the throw-out bearing back outwards, clamping the clutch disc again between the pressure plate and the flywheel. In this case, the transmission is re-engaged with the engine, and the vehicle can be driven.

The image below depicts a vehicle with the engine and transmission mounted longitudinally. The gear shift lever is positioned directly above the transmission as it is located under the center console in the interior.

Clutch Defects:

A clutch is a wear part. With good driving habits, a clutch can easily last 300,000 km. However, for individuals who let the clutch slip a lot and drive frequently in urban traffic, the clutch may wear out after just a few tens of thousands of kilometers. When a clutch wears, it can be detected by the following points:

- Clutch pedal is very high; With a hydraulic clutch, this does not necessarily mean the clutch is worn. If it also tends to slip, it is indeed wearing out. In a mechanical system, it might mean it is incorrectly adjusted. However, if a light force on the pedal causes it to slip, then the clutch is worn.

- Clutch slips; During full acceleration, the engine speed increases faster than the vehicle accelerates. This is usually accompanied by a burnt (clutch disc) smell. This clutch is severely worn and soon will not be driveable.

- During acceleration in 4th (or higher gear), if the clutch pedal is lightly touched, and it starts to slip, the clutch is wearing out.

- If in a higher gear (4th or above), acceleration is attempted, and the clutch is briefly pressed and released while the gas pedal remains pressed, the clutch should quickly re-engage. If it continues to slip for a longer time, it is wearing out.

- Clutch operation is heavy, requiring significant force on the pedal; the pressure plate is often the cause here. Usually, it is a combination of a worn clutch and pressure plate, both of which will need to be replaced.

- Clutch does not release when the clutch pedal is fully depressed; Likely a problem in the clutch cylinder or pressure plate. A diaphragm spring in the pressure plate might be broken.

- Clutch shudders or chatters when released; This could be dirt on the clutch disc, a glazed clutch, or an excessively worn dual-mass flywheel.

If the clutch rarely slips (indicating good driving habits), the plates can become dirty. By briefly and firmly slipping the clutch, the plates can burn clean again. When driving, put the car in a high gear (4 or 5), half press the clutch, and accelerate. Do not do this for too long, as the plate can burn. If done carefully, the dirt on the clutch disc burns off, and the shudder may disappear permanently. - If a scraping noise is heard when the car is in neutral and the clutch is not engaged, and the noise vanishes when the clutch is pressed, the throw-out bearing may be making the noise. It is located between the lever and the pressure plate. If it is unloaded, it may rattle. Replacing this part is the only solution.