Imbalance:

Every tire, whether new or old, has small irregularities. The tire is always slightly heavier on one side than the other. As a result of these irregularities, an imbalance occurs during driving due to radial forces (from the center outward). This imbalance can be felt by the vibration of the steering wheel or the entire vehicle.

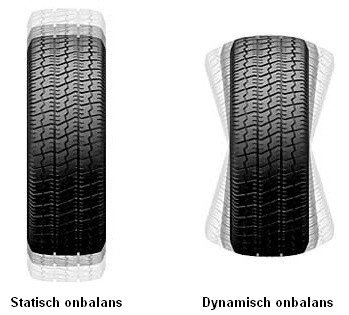

There are two different types of imbalances: static and dynamic. With static imbalance, the tire moves up and down because the weight at, for example, the top of the tire is greater than at the bottom. The forces on the rolling tire are not evenly distributed. As the revolutions per minute increase, the force of the imbalance also increases. This makes the vibration greater. With static imbalance, the entire vehicle will primarily vibrate.

With dynamic imbalance, the tire moves more from inside to outside, creating a swaying effect. This is especially noticeable in the steering wheel when it moves rapidly left to right. The vibration will also increase at higher speeds.

Balancing:

After mounting the tire on the rim, the entire wheel must be balanced. The wheel is placed on a balancing machine, which can precisely determine where the irregularities in the tire are and how large they are. By hammering or sticking a weight to the indicated side of the rim, this imbalance is corrected. The screen shows on the left side how much weight must be stuck to the inside of the rim, and naturally to the right side on the right. By rotating the wheel to the position indicated by the machine, the weight can be applied to the rim.

Once the cover is closed again, the wheel starts spinning, and the imbalance is measured again. The screen should now indicate 0 on both the left and right sides. If there is imbalance again (for example, 5 or 10 grams), it means that balancing was not done properly, and the weight should be removed and balanced again. Otherwise, the “excess weight” would also cause imbalance and would need to be compensated again.

If the rim is damaged or bent, there is sometimes no choice but to place weight at several points because there is imbalance at different locations. A bent rim can usually be balanced to 0 grams of imbalance, but it will still cause the vehicle to vibrate due to the wheel hop it causes.

Amount of Imbalance:

A normal wheel usually has between 10 and 30 grams of imbalance. Occasionally, a wheel may have no imbalance at all, because the tire coincidentally aligns perfectly with the rim’s position. The irregularities in the tire precisely compensate for the irregularities in the rim. Modern balancing machines can locate this point.

If a wheel has more than 50 grams of imbalance, it is advisable to rotate the tire in relation to the rim. If the rim itself also has an irregularity that lies exactly at the same point as the tire, the imbalance will be increased. By rotating the tire, the imbalance can be offset against each other. It is best to rotate the tire half a turn the first time. If this does not improve or makes it worse, then turn the tire a quarter turn. If the imbalance is still too high, the tire can be further rotated another half turn (now the tire has had four different positions on the rim). If there is excessive imbalance in all four positions, the quality of the tire or rim may be in question. A defect in the rim is usually noticeable during rotation; the wobble is easily recognizable.

Weight:

The ‘weight’ used to balance wheels is actually no longer lead, but zinc. This is far more environmentally friendly and cheaper. Nevertheless, it is still referred to as lead (or balancing weight).

There are two types of weights: clip-on and adhesive weights. Clip-on weights are always used on steel rims. The weight is hammered onto the rim.

Aluminum rims often have a special rim edge on the inside where weights can be clipped. This is usually not visible and is cheaper than adhesive weights. Clip-on weights for aluminum rims differ from those for steel rims; the hook on the weight is wider and larger than that on the steel rim.

Each weight has its own mass. The higher the weight, the larger the size. The weights range from 5 to 60 grams, in 5 gram increments.

Adhesive weights are always used on aluminum rims. The weight is glued inside the rim. Adhesive weights are available by individual weight (from 5 grams to 60 grams in 5 gram increments) or as strips that need to be torn to the desired size. (1 block is 5 grams, so 4 blocks are needed for 20 grams).