Atkinson-Miller Cycle:

Engines with a high compression ratio can deliver significant power. However, at low engine load (part load), the engine is inefficient: even at low load, high pressure builds up above the piston, causing inefficiency, which is undesirable in this case. To achieve high efficiency at part load with a higher compression ratio, some manufacturers use the Atkinson-Miller principle. The names Atkinson and Miller are sometimes confused and misused. The next section clarifies the differences and similarities of these inventions.

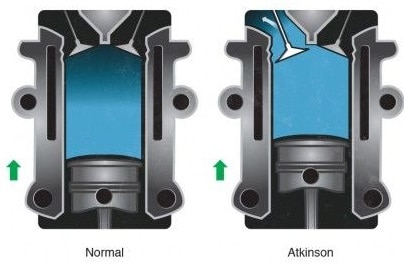

With the Atkinson-Miller principle, the intake valve remains open longer during the compression stroke at part load (approximately 20 to 30 crankshaft degrees): the intake air partially flows back into the intake manifold. The amount of air above the piston after the intake valve closes is much lower than in engines where the intake valve closes at the end of the intake stroke. With less air above the piston, less air needs to be compressed (less resistance during the compression stroke). The amount of fuel to be injected is also less: less air means less fuel.

The consequence of the later closing of the intake valve is a lower volumetric efficiency. This reduces engine power but improves overall combustion. The Atkinson-Miller cycle is ideal for hybrid vehicles, as the combustion engine is no longer the sole power source but is supported by the electric motor or is only used to charge the battery pack (series hybrid). Additionally, by changing the valve timing under other operating conditions than part load, the timing of the intake valve can be advanced.

Several manufacturers apply the Atkinson-Miller principle to the combustion engines of their hybrid cars. These are mainly Korean and Japanese manufacturers: Hyundai, Honda, and Kia.

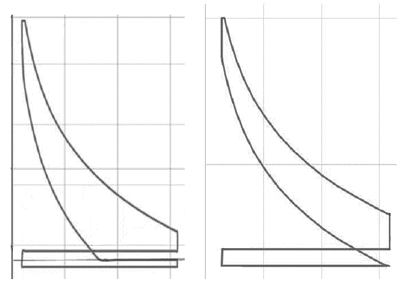

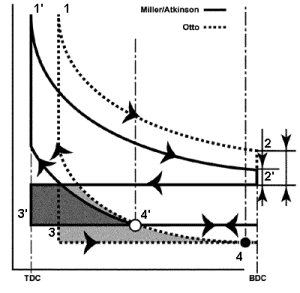

The images below show the indicator diagram and the PV diagram of a normal gasoline engine alongside the engine with the Atkinson principle. Because with the Atkinson principle, compressing the air starts later in the compression stroke, this is reflected in these diagrams. The reduction of compression loss increases thermal efficiency.

History of the Atkinson-Miller Technology:

In the previous section, we discussed the application of the Atkinson-Miller cycle. In the literature, the names of the techniques of Atkinson and Miller are often combined, while they were two separate inventions with the same goal. Below is the history of the Atkinson and Miller principles described.

Atkinson: James Atkinson (Great Britain, 1882) worked on his invention by which he could increase the efficiency of a piston engine by extending the power stroke. Through a complex system of rods and toggle mechanisms, the piston stroke of the power stroke could be higher than in the intake stroke.

The animation shows the four strokes in the well-known four-stroke process:

- intake stroke (intake, ansaugen)

- compression stroke (compression, komprimieren)

- power stroke (expansion, arbeiten)

- exhaust stroke (exhaust, ausstossen)

The Atkinson engine was not further developed at the time because this design was too complex and there was too much power loss.

Miller: Ralph Miller (United States, 1947) developed the technique in which the intake valve closes later to reduce the compression end pressure (see the previous section). By changing the valve timing, the same goal is achieved as with the Atkinson principle: to mechanically limit energy loss in the compression stroke with less air. The difference between the Atkinson and Miller principles is that the Atkinson physically makes different compression and power strokes, while Miller achieves the same thermodynamic result with delaying the intake valve timing.

Related page: