SCR Catalyst and AdBlue:

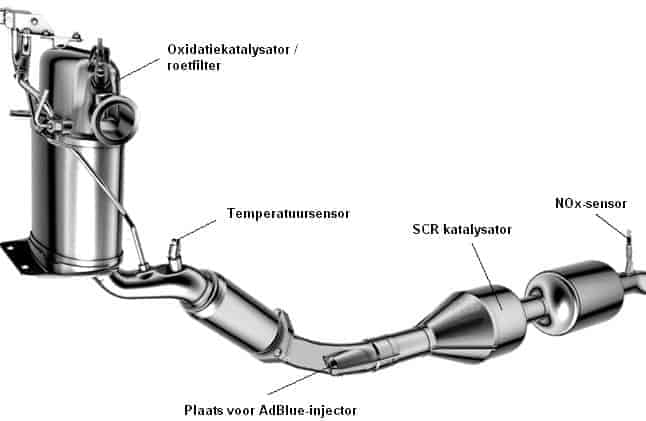

Certain modern diesel engines have a “Selective Catalytic Reduction” catalyst in the exhaust. Together with the AdBlue dosing system, this provides exhaust after-treatment. The goal, just like the EGR, is to reduce emissions of NOx (nitrogen oxides). NOx forms at high combustion temperatures.

The operation is as follows: the NOx in the exhaust gases is stored in the SCR catalyst. The SCR catalyst is located behind the particulate filter in the exhaust. When a certain amount of NOx is stored in the catalyst, AdBlue is injected into the exhaust with an injector. Immediately after the injection, the hydrolysis process begins; this is a splitting of a chemical bond by a reaction with water. During this hydrolysis process, the AdBlue is converted into ammonia and carbon dioxide. Then the ammonia and carbon dioxide enter the SCR catalyst.

In the SCR catalyst, the ammonia reacts with the NOx (nitrogen oxides). The harmful substances in NOx are converted into the harmless substances nitrogen (N2) and water (H2O). Before the nitrogen and water exit through the exhaust into the atmosphere, the NOx sensor measures how much NOx is still present in the exhaust gases. This is described in the next paragraph.

By using AdBlue, diesel engines can meet the Euro 5 and 6 standards.

The AdBlue is located in a separate tank elsewhere in the vehicle. This can be either in the engine compartment or near the fuel tank.

The average consumption of AdBlue is about 3 to 5% of diesel consumption. Therefore, AdBlue needs to be refilled less frequently than refueling.

When the AdBlue tank is almost empty, a warning light or message will appear on the dashboard several thousand miles before the tank is actually empty, providing the driver with time to refill the system. If the driver ignores the warning and the tank is completely empty, the engine electronics might prevent the engine from starting. When there is no AdBlue in the tank, the vehicle no longer complies with environmental standards. Once the system recognizes that AdBlue is again present in the tank, the engine can be restarted.

Injection of AdBlue:

AdBlue is pumped from the storage tank to the AdBlue injector under a pressure of around 5 bar. This high pressure is required to ensure proper atomization into the exhaust gas. The injector is controlled by a PWM signal via the engine electronics.

The engine electronics determine the amount of AdBlue to inject. The dosing must be as precise as possible. The dangers of incorrect dosing are as follows:

- insufficient injection: not all NOx is converted.

- excessive injection: emission of harmful ammonia because the chemical reaction in the SCR catalyst is insufficiently achieved.

The NOx sensor behind the SCR catalyst measures the remaining NOx. When the NOx level is too high, the engine management system will ensure that more AdBlue is injected. Nowadays, an ammonia sensor is also used to measure excess ammonia, allowing the amount of AdBlue injected to be reduced.

Refilling AdBlue:

AdBlue must be refilled periodically. As described in the previous paragraph, one cannot wait too long to refill once the AdBlue tank is nearly empty. The driver is responsible for checking the fluid level and refilling it.

In passenger cars, the filling points can be located in several places. In exceptional cases, the AdBlue filling opening is behind the rear bumper, but it is usually located behind the fuel flap next to the fuel cap, or in the engine compartment. The filling opening is recognizable by the blue screw cap.

AdBlue is always in a sealed bottle. Contact with outside air should be avoided as much as possible since moisture is present in the air. If AdBlue comes into contact with moisture, it can crystallize. Therefore, a screw connection is possible between the bottle and the filling opening, as shown in the image.

The bottle should be screwed onto the vehicle’s filling opening. By pressing the bottle against the spring force of the screw cap, AdBlue slowly flows through the filling opening into the vehicle’s tank. Refilling can continue until the bottle no longer empties; then the AdBlue level in the vehicle’s reservoir is at maximum.