Subjects:

- Measuring Piston Ring Clearance

- Measuring Slot Play

- Fitting Piston Rings

To measure piston ring clearance:

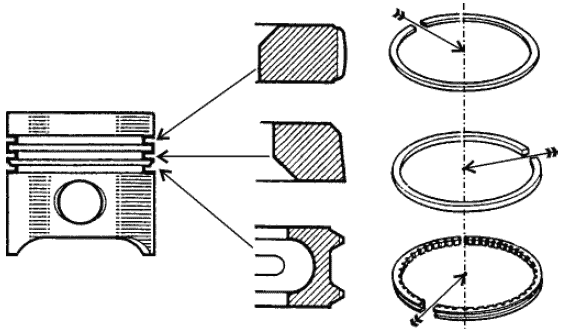

Pistons are often equipped with two compression rings and one oil scraper ring. When replacing piston rings, the clearance in the piston ring groove and the lock clearance must be checked.

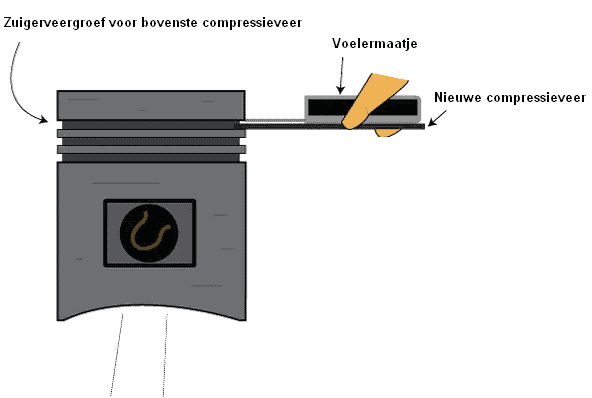

The following figure shows the measurement in which the clearance in the piston ring groove of the piston is checked. A feeler gauge and a new compression ring are slid into a piston ring groove at the same time. The play should in most cases only be between 0,025 and 0,050 mm.

To measure slot play:

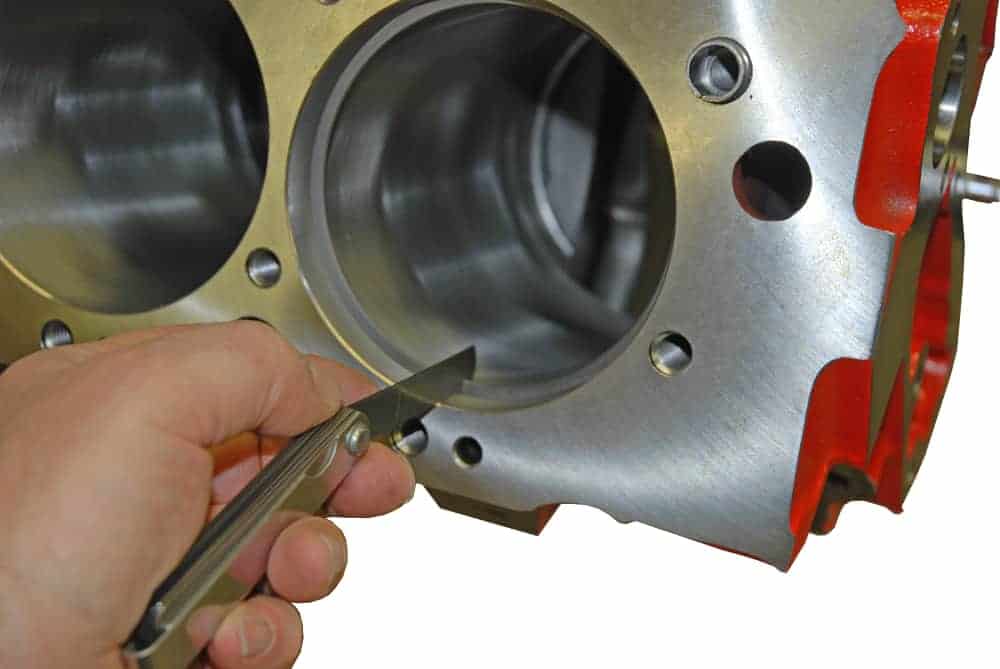

The lock clearance is the space between both ends of a piston ring when mounted. To measure the lock clearance, we insert the piston ring into the corresponding cylinder. We keep the piston ring relatively high in the cylinder; any wear on the cylinder wall (often around the center) does not affect the measurement.

With a feeler gauge we check how much space (read: lock play) there is between the ends.

- too large a lock clearance results in a lot of leakage gases and therefore loss of compression;

- if the lock play is too small, or no lock play, friction, and thus wear, or even a jam can be caused.

As a rule of thumb, a clearance of 0,05 mm per centimeter of piston diameter applies.

Fitting piston rings:

When carrying out assembly work, pay close attention to the correct mounting position. In most cases the piston rings are marked: “Top” or “Oben”. This indication must then point to the piston bottom (top).

The piston rings must also be positioned in such a way. In the example, the piston spring locks are rotated 120 degrees from each other. Make sure that the piston ring locks are not exactly one under the other at all times.

Related pages: