Subjects:

- Functions of a band

- Different parts of a band

- Tire data and size markings

- Choice of tire size

- DOT code

- Tire profile

- Wear

- Flat tire & repair

- Run-Flat tires

- Price to quality ratio

- Rims; Designations and indications (including pitch size and ET value)

- Valve and air pressure

- Wheel bolts

Tire functions:

A tire has a number of functions, which every tire sold of any price must meet:

- Roles

- Carrying the vehicle

- Transmission of driving and braking forces

- Send

- Vibration dampening

- Long lifespan.

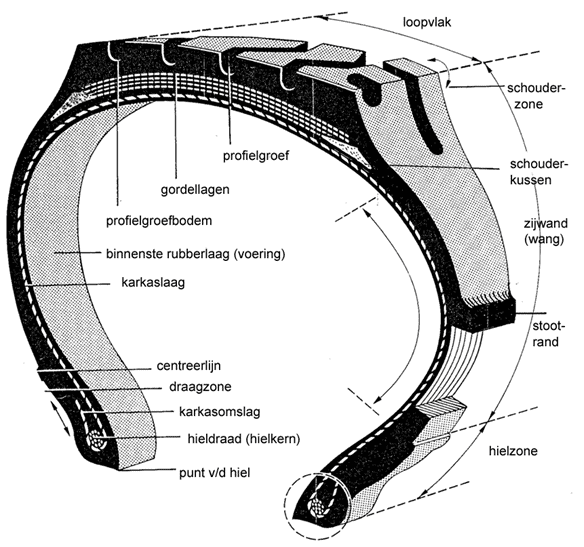

Different parts of a tire:

The side of the tire is called the 'Wang'. The cheek is constructed as smoothly as possible to make a positive contribution to comfort. Somewhat sportier tires have thicker and stiffer sidewalls to give better responsiveness when steering. However, the disadvantage of this is that the comfort deteriorates. The bumps in the road surface are then more noticeable, which can be experienced as unpleasant. The construction of the tire carcass gives the tire its strength. The purpose of the tread is to have grip on the road surface and to drain rainwater. The tread has main grooves, and profile between the main grooves. (See the Tire profile section there)

The bead keeps the tire airtight on the rim. In contrast to the classic tires, this means that no inner tube is needed anymore. Only the outer tire is sufficient. These are also called tubeless tires.

Information and markings on the strap:

The sidewall of a car tire always shows the brand and type of the tire. There are also some numbers and letters on it. These numbers and letters show you what size it is (width, height and diameter of the hole where the rim is located), what maximum speed you can drive and how much weight the tire can carry. Below is an indication of what this data means:

Here is mentioned as an example a tire with the size 205/55 R16 91v

205 = the width of the tread in mm (ie 20,5 cm wide).

55 = the height/width ratio of the sidewall of the tire to the width of the profile (the height of the sidewall of the tire is 55% of the width of the tread). This means that if the width of the profile is 20,5 cm, the height of the sidewall is 55%, so it is 11,2 cm high.

R = Radial tire (there are radial tires and diagonal tires). Nowadays, due to the firmness of the tire, only radial tires are used in passenger cars.

16 = Inch of the rim around which the tire goes.

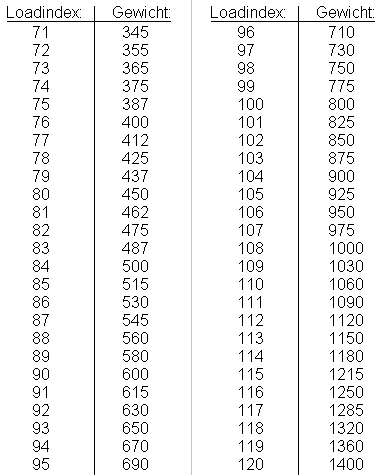

91 = Load index (the maximum weight allowed on the tire). The load capacity must always be equal to or higher than the weight that the car may be fully loaded. (See the table below)

V = Speed coding (the maximum allowed speed for the tire). According to the law, tires with a lower speed code may never be fitted than the maximum speed of the car, even if the driver always drives calmly and never faster than 120 km/h.

The tables below show the load index (capacity index) and the speed coding. The weights are in kg and the speeds in km/h.

The tire from the example (205/55 R16 91v) may therefore be mounted under a car whose max. speed, according to the manufacturer's specifications, is below 240 km/h and which technically may not be loaded more than 615 kg on 1 tyre.

It is not correct to divide the “Permitted max. vehicle mass” stated on the registration certificate by 4 in order to calculate the max. weight per tire. To calculate it correctly, the weight of 1 axle must be divided by 2. The maximum axle loads from the front and the rear must be known. These axle loads can then be divided by 2 to determine the maximum weight per tire.

Choice of tire size:

The same tire size should always be mounted as it came from underneath. The speed encoding and load index may deviate, as long as care is taken not to fall below the minimum.

When a conscious decision is made to mount a different size (eg when choosing larger rims or a smaller winter wheel set), care must be taken to ensure that the static rolling circumference remains the same. The static rolling circumference is the distance the wheel travels after one complete rotation. There is even a considerable difference in circumference between the sizes 225/40R18 and 225/45R18.

When the tire circumference changes, the car's speedometer indicates a higher or lower speed than the actual driving speed. Failures in the ABS system can also occur when 2 different sizes are mounted under 1 car.

To prevent this, the other tire size must still have the same static rolling circumference. To check this, the currently installed tire size with the desired tire size can be compared with the handy calculator, on the page: tire height and static rolling circumference calculator. With this calculator, the circumference of the tire can be calculated very accurately and the tire size can be chosen that hardly deviates from the factory data.

DOT code:

All tires have a DOT code. This is determined during the production of the tire and applied to the tire. From this code can be identified the identification code, manufacturer codes and the most important; the production date can be traced. Below is a summary of the different characters of the DOT code. These codes refer to the image below.

- (DOT): The “Dot” designation, which is an abbreviation of: Department Of Transportation. This indicates that the tire meets safety standards in the United States.

- (HWN5): Factory identification code

- (P2HK): Additional codes from the manufacturer

- (0503): Production date: The first 2 digits indicate the production week (the 5th week), and the last 2 digits indicate the production year (2003).

For tires manufactured before the year 2000, this consists of only 3 digits (the last digit represents the year).

Examples:

319: Week 31 of the year 1999

2812: Week 28 of the year 2012

A tire 6 years or older is more likely to develop dehydration and other defects. That is why it is necessary to pay attention to this when buying used tires. Tires older than 10 years have reached the end of their life cycle. Even if the profile is still sufficient, it is still wise to replace the tires.

Tire profile:

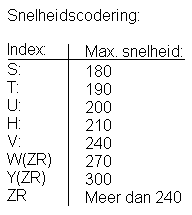

The profile of the tire consists of a number of channels that ensure that rainwater is drained. When driving at 100 km/h in rainy weather on a wet road surface, the tire rolls over up to 10 liters of water per second. If the tread depth is too low, the tire would not be able to drain the water fast enough and could float on the water. That makes braking and steering impossible. This is called aquaplaning. It is therefore important that there is always sufficient profile in the tire. With worn, or obliquely worn tires, the water-draining properties are therefore also a lot less.

New tires have a profile of 8mm. Tires with a profile of 2,5mm or less are noted as an AC point for the APK. If the tires are 1,6mm or less, this is a rejection. It is therefore wise to replace the tires if they are below 3mm. At 2,5mm, aquaplaning can already occur with a lot of rain.

The table gives a good indication of tread depth. The red marks on the tire image indicate the indicators. These have a height of 1,6mm. Once the indicator is level with the rest of the tire, the tire has a profile of 1,6mm or less. It is then necessary to replace the tires.

Wear:

Tires naturally wear out as the car is driven a lot. With a calm driving style, the tires will last longer than with a sporty driving style that often involves faster acceleration. There are also other causes that will cause the tires to wear faster, namely due to:

- Incorrect wheel positions, so that the tires are not square to the road surface while driving. This can be caused by a wrong camber or a wrong adjustment in the track. (See the Wheel alignment chapter.) The tires can then wear crookedly, so that the tires are completely worn on the side, but have 4 mm profile left in the middle (see image below).

- Defective and worn (ie too flexible) shock absorbers. The tires will sway and jump more because they follow the movement of the spring more. Cupping can then occur. This means that the tire is no longer completely round, but has a difference in height in several places. While driving, a buzzing sound can be heard, which can be very annoying.

- Imbalance in the wheels. Because there is a constant vibration at the same place, the wear will be higher there than at another point.

- Tire pressure. With a (much) too low tire pressure, the tire will wear up to twice as fast. That is why it is always recommended to check the tire pressure every month or at least every other month. Other important benefits of correct tire pressure are safety; Fuel consumption; if the tension is too low, it can rise very quickly due to the increasing rolling resistance. A voltage that is too low can also affect safety. The tire may then have little grip on the road surface. The car may slide earlier. The correct tire pressure is indicated on a sticker on most cars in the fuel filler flap or in the opening of a door. In any case, never let the tire pressure fall below 2 bar.

- Driving style. Due to a smooth driving style, with hard acceleration and hard cornering, the wear also increases significantly.

There are wear indicators in the tire profile. These wear indicators are 1,6mm thick. When the tire profile is so worn that the height of the main groove is equal to the wear indicators, it is necessary to have the tire replaced. From this wear limit it is dangerous to drive through rainy weather.

The picture shows the tire of a car with too positive camber. The carcass is visible, while the profile appears to be in order from the outside.

Flat tire & repair:

It can happen with every tire that it goes flat. This usually happens because a sharp object, such as a nail, is stuck in the tread. In modern cars, the driver is warned by the TPMS tire pressure indicator light. If you do not drive with a flat tire, but a spare wheel is fitted in time, it can in most cases still be repaired. If you continue driving with a flat tire and a lot of air has disappeared from the tire, the sidewall of the tire can be damaged. If this is the case, the tire should always be replaced.

If the tire has a puncture in the sidewall due to a nail protruding through the outermost part of the tread, or if the tire is punctured on the side (the sidewall) with a screwdriver, the tire must not be repaired. The sidewall of the tire is very vulnerable because there is quite a bit of movement in it. The tire will bounce on this, and when cornering, the sidewall will also allow for the lateral movement of the tread (what is called the drift angle).

However, a tire should never be repaired if the hole is larger than 7mm, or if the leakage is outside the tread area, eg in the sidewall of the tire or just next to the profile. Repairing 1 tire several times (due to different leakages) is also not recommended. The tire still gets weakened by a repair. Manufacturers can no longer guarantee safety with more than 2 or 3 repairs on 1 tire.

Nowadays, a tire repair kit is often supplied instead of a spare wheel. This fluid is intended to temporarily close the leak. If there is a stud in the tire, the liquid will form a solid compound around the stud. Then no more air can escape. However, this is a temporary fix. You must then drive past the garage to carry out the final repair. The disadvantage of the liquid is that it does not seal in the long term (the tire can start to leak again). Also causes a lot of imbalance in the wheels due to the weight of the fluid that constantly moves when the wheel rolls, but that is not a disaster for a trip to the garage. It is also difficult to remove when the tire is removed from the rim.

Repair from the outside:

The tire can be repaired in the garage from both the inside and the outside of the tire. The tire does not have to be disassembled from the outside and a plug is placed in it that closes the hole. This method should be seen more as an emergency repair and not as a permanent repair. The prop can come out of the tire, for example, at high vehicle speeds. Also, when performing this emergency repair, the inside of the tire is not looked at; If the tire has been driven for too long with under-inflated tires, damage to the inside of the sidewalls may be visible. Over time, this can lead to a blowout.

Most emergency services or garages that repair the tire in this way often advise the customer to have the tire repaired from the inside within a short time. Because the tire is then removed from the rim, the inside of the tire can be checked for damage and a final repair is carried out with a so-called “umbrella”.

Repair from the inside:

The tire has to be disassembled from the inside and a plug in the shape of an umbrella is pulled from the inside to the outside. This will fill the gap. On the inside is the flat part which ensures that the plug cannot come out and seals the hole even better. This repair from the inside is always recommended as it is the safest. However, it takes more time, so in some cases a conscious choice is made for a repair from outside. The disadvantages and risks are described above.

Because there is often confusion about the correct order of repair, the following 11 steps describe how the repair should be carried out:

Step 1:

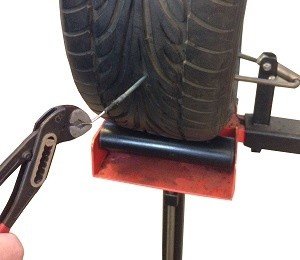

Remove the tire from the rim.

Step 2:

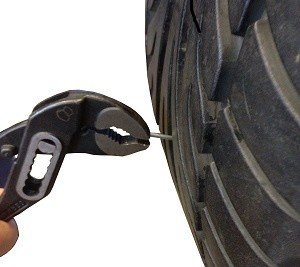

Remove the object from the belt.

Step 3:

Make the hole bigger with a drill bit so that it is big enough to move the plug through.

Step 4:

Lightly sand the area around the hole and degrease it well. Do not sand too hard; when bits of rubber come loose, repair becomes a lot more difficult. The sanding is only intended to roughen the surface so that the adhesive can adhere properly.

Step 5:

Insert the plug through the hole, but do not fully tighten it yet. Make sure that the flat part of the plug does not touch the inside of the tire.

Step 6:

Apply the special blue adhesive to the surface of the tire and to the underside of the plug. Make sure there is a layer of glue, but don't spread too much! Thick blobs or drops do not dry up.

Step 7:

Wait 10 to 15 minutes for the glue to dry and pull the plug all the way through the tire. If the glue has not completely dried, the plug will not stay in place. So wait long enough.

Step 8:

Roll over the plug with the appropriate roller to press it firmly. If you don't have this roller, use the back of a screwdriver to roll over the plug. When the edges around the plug slowly rise again and therefore do not stick, the glue had not dried long enough. In that case, remove the plug again. If the flat part of the plug sticks neatly around, proceed to step 9.

Step 9:

Spread the vulcanizing adhesive over the entire repaired area, creating a protective layer over the edges of the plug.

Step 10:

Cut the end of the plug, which protrudes from the outside of the tire, as close to the tire as possible. To do this, pull the plug briefly, so that no part of the plug protrudes after cutting.

Step 11:

Check with soapy water or a leak detection fluid or soapy water that the tire is no longer leaking in this area. If air bubbles form, the tire must be disassembled again and therefore start again at step 1.

The repair should only take place in the tread. This is indicated in green in the image below. If the object is too far to the side (in the red part) of the tire, the tire may no longer be repaired for safety reasons. This is too close to the sidewall of the tire and is where the tire bounces the most. It can be assumed that three quarters of the surface can be repaired. Three quarters correspond to the green mark in the picture.

Driving for too long with a flat tire can damage the canvas. The tire in the picture on the right comes from a VW Caddy. It's a wonder this tire didn't pop while driving. The tire is of course beyond repair and must be replaced. If there is a small bump on it, as can be seen on the right side (at 3 o'clock), this is already rejected for the MOT because it is not safe.

Make sure the spare wheel always has enough tension. Check this every year. A full-fledged spare wheel should be inflated to ±3 bar and a homecoming (emergency wheel) to ±4,2 bar.

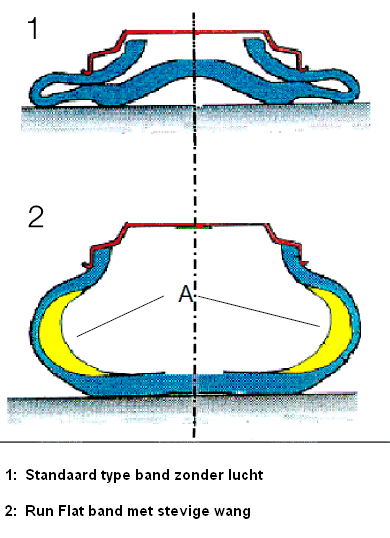

Run Flat tires:

Run-Flat tires have the advantage that you can continue driving with a flat tire. That is because the stiffness of the cheek is great. If the tire loses air, the stiffness prevents the rim from hitting the ground. It is then not really visible that the tire is flat. The cheek simply stands upright, while there is too little air in it. It must then be made clear via a message on the on-board computer that there is a puncture, otherwise it will not be visible. This is done through the TPMS (Tyre Pressure Monitoring System).

It can of course be noticed while driving because the car shows different cornering behaviour. However, many people think that if the Run-Flat tire is punctured, they can always continue driving until it is repaired. However, this is not true. A run flat tire that is punctured must always be kept at a pressure above 1 bar. If you continue driving with a pressure below 1 bar, the sidewall will be damaged, and the tire must also be replaced. If the tire is kept above 1 bar with a compressor from the trunk, it can usually still be repaired afterwards. Disadvantages of Run-Flat tires are in the first place the price (which is often much higher than a tire from the normal type) and comfort. Due to the stiffness of the sidewall, the tire will also be much stiffer, and therefore less comfortable. Run-Flat tires cannot simply be mounted on standard rims. The shape of the rim is unsuitable for that. The other way around is possible; Standard tires can be mounted on Run-Flat suitable rims, but the danger is that in that case there is often no tire pressure monitoring system on the car and a flat tire is therefore not noticed quickly enough.

Price to quality ratio:

There are many types and brands of tires. There is often a choice of different prices for a certain size. Usually the price also says a lot about the quality of the tyre. You can often find prices for a certain tire size between 60 and 200 euros. The cheapest tires are often of lower quality. This is noticeable in the driving characteristics (for example, leaning faster in the bend, sliding faster on a wet road surface). A cheap tire will often wear harder and sometimes crookedly due to the quality of the rubber and often also makes more noise. Fuel consumption may also increase due to the possibly higher rolling resistance. The choice for an A-brand is therefore often the best.

Rims; names and indications (including pitch size and ET value):

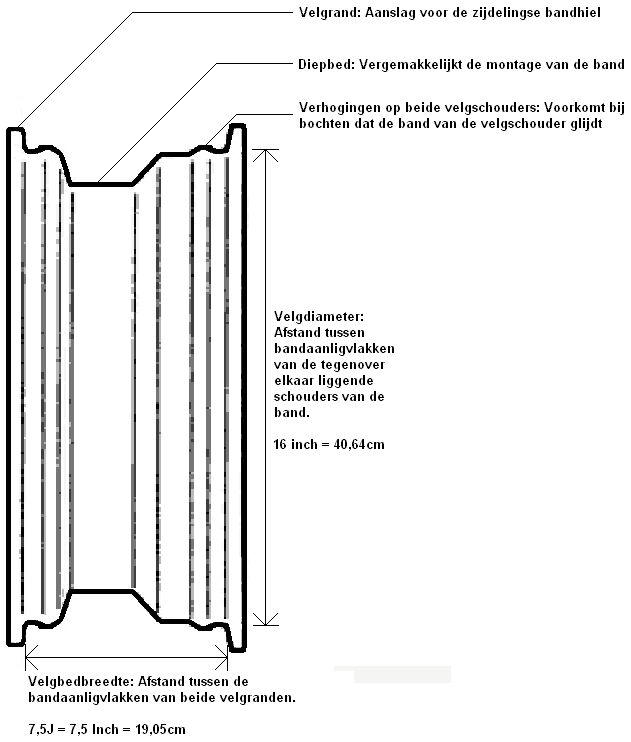

The picture shows a drawing of a rim. After mounting, the bead of the tire is mounted between the rim flange and the elevations on both rim shoulders. The elevation prevents the tire from slipping from its position on the rim. If that were to happen, the air would spontaneously escape and the rim would hit the road. This could also happen, for example, with a blowout or if you continue driving with a flat tyre.

There are different markings on a rim. These are usually mounted on the inside on a spoke or on the hub. An example of this is: 7,5J x 16 LK 112ET 35.

The data 7,5J (width) and 16 (height) can be seen in the image above. We now move on to the rest of the data, such as the pitch (112) and ET value (35);

pitch size:

The number 112 is the diameter in millimeters in which the wheel bolt holes are located. This is also known as the pitch size. Each car has a specific pitch, which is noted / stamped in the factory specifications or on the rims that are under the car. At the 5 x 112,5 pitch, an imaginary circle must be drawn through the center of the wheel bolt holes. An example of this can be seen in the two images below. The diameter of the circle is the pitch size. With the 4 x 100 pitch you can measure between center bolt hole to center bolt hole.

Multi stitch:

There are also rims with multiple wheel bolt holes (in the picture no less than 10). These rims can be mounted under several types of cars with different pitch sizes.

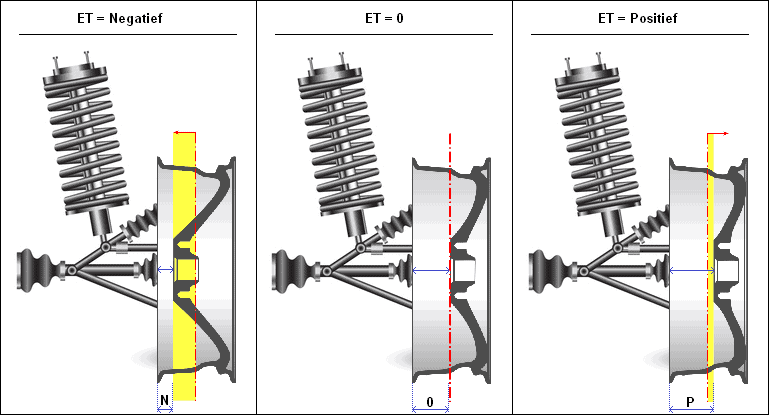

ET value:

ET 35 stands for the ET value. The ET value (from the German “Einpress Tiefe”) stands for the distance between the hub and the center of the rim. In Dutch it is also called the “wheel bulge” or “offset”. The greater the distance between the hub and the center of the rim, the higher the ET value. Below is an image with explanation:

Most rims have a positive ET value. The hub of the rim will then be further out than the exact center point of the rim. With a rim with an ET value of 35, the hub is 35mm (ie 3,5cm) from the centerline of the rim (the red dotted line). The distance between the hub and the centerline of the rim is marked in yellow in the illustrations. If one decides to mount other rims under the car, the ET value must therefore be taken into account. For example, it is possible that the rims under the car have the designation 7,5J ET 35, and that the rims with 7,5J ET 50 do not fit.

At ET 50, the yellow mark in the top right image will increase in size.

This means that the rim is moved more inwards. This could cause the rim to hit the shock absorber. Not only will the chance of a run-up be increased, but the driving characteristics will also deteriorate. This problem can be solved with track wideners. These are metal discs that are mounted on the wheel hub – between the brake disc and the rim. In this case, the difference between the ET 30 and ET 50 is therefore 20mm (2cm). The problem is solved by installing 2 cm track wideners. A few remarks about wheel spacers: In the last mentioned example, the lack of distance is compensated by the wheel spacers. However, it is not recommended to mount it if the ET value is correct. The wheels are a little further out, but the sanding jet (and therefore the driving characteristics) change beyond the factory tolerances. Despite the fact that this often looks beautiful and sporty optically, it does have disadvantages.

Valve and air pressure:

The valve is mounted in the rim of a car, so that the air remains in the tire. The air in the tire is pumped up through the valve. It is recommended to also replace the valve when replacing the car tires as it dries out over the years. This can cause leakage, causing the tire to deflate faster.

The valve is made of rubber and is closed by means of a valve cap. This is not intended to keep the tire pressure, but to keep dust and other dirt out of the inside of the valve. Inside the valve there is a metal nipple with a spring that is screwed into the valve housing (see the picture below). When air is pumped into the tire, the pressure from the outside is greater than from inside the tire. When the air pressure in the tire pump (outside) is 8 bar and in the tire it is 2 bar, the air is forced into the tire through the nipple.

In the situation shown in the illustration, air escapes, because here the nipple is pressed in by pushing an object against the spring force of the valve. The air inside the tire (eg 2 bar) is higher than the outside air pressure (1 bar), allowing the air pressure in the tire to escape to the outside. When the air pressure in the tire is higher than the outside air pressure, the air presses against the bottom of the nipple, sealing it off. The air cannot escape due to its own pressure.

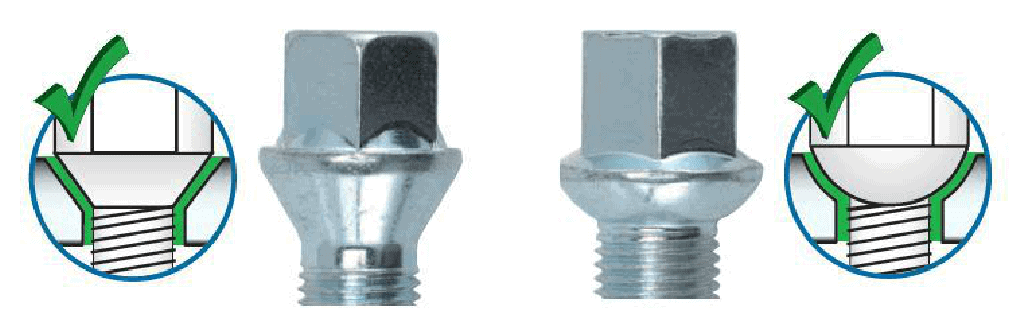

Wheel bolts:

Wheel bolts come in two types, regardless of diameter and length: conical and conical. When mounting other wheels, it should be noted that there may be a difference in the head that clamps in the rim. The picture shows the difference in the wheel bolts; conical on the left and conical on the right. If the bolts are accidentally swapped, there is a good chance that the bolts will come loose while driving.

Make sure that the correct wheel bolts are also used for the spare wheel. If other wheels with conical bolts are fitted and the vehicle is fitted with rims with convex bolts as standard, the spare wheel cannot be mounted under the vehicle with the bolts of the wheels in the event of a puncture. In this case, always put a set of correct bolts in a compartment near the spare wheel and (if applicable) inform a customer about this.