Subjects:

- Flywheel

- Dual mass flywheel

Flywheel:

A flywheel ensures that the engine turns more evenly. An internal combustion engine supplies power to the crankshaft the moment ignition takes place in the cylinder; then the crankshaft of the engine 'bumps' slightly forward again. This happens twice every rotation of the crankshaft. The flywheel has a large mass and absorbs part of that energy. The motor will make less jerky movements and therefore run more smoothly and evenly. The heavier the flywheel is, the more difficult it is for the engine to start the flywheel. Once the flywheel turns, it is more difficult to slow it down. Because of these properties, the shocks released during the power strokes will be less.

When the engine has more cylinders, (eg 8 instead of 4) there have been many more exhaust strokes per crankshaft rotation. As a result, the engine runs more stable on its own and a lighter flywheel can therefore be mounted.

The flywheel is mounted at the end of the crankshaft. The clutch is mounted on the flywheel, with the gearbox attached over it. The starter motor is located on the outside of the flywheel.

In racing, a flywheel is often turned; this means that a piece is ground off, making it lighter in weight. The advantage is that due to the weight reduction, the engine will accelerate faster, because less mass has to be driven. The disadvantage is that the engine will not run as cleanly when idling as with an original flywheel.

Dual mass flywheel:

Nowadays, a dual-mass flywheel is increasingly installed (also called dual-mass flywheel or dual-mass flywheel). The advantage of this flywheel compared to a single flywheel is that this flywheel dampens even more small vibrations. It also reduces noise that is normally caused by vibrations between the engine and gearbox.

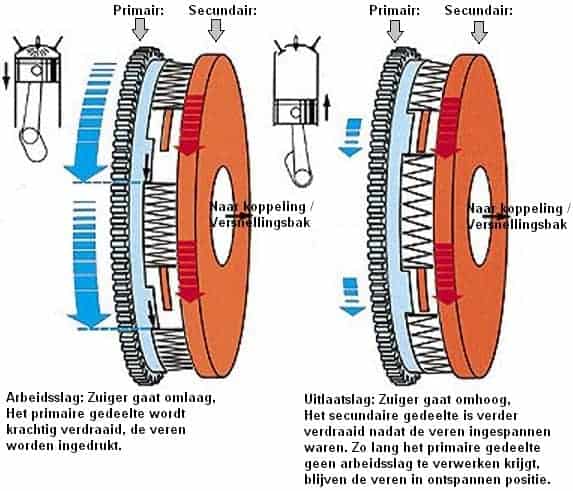

With a dual flywheel, the total mass of an ordinary flywheel is divided into two parts, namely the primary and secondary flywheel. These two parts of the flywheel are mounted together with ball bearings and with a damping system with coil springs. The primary part is on the crankshaft, the secondary part on the clutch side with pressure plate. The driving force is transferred from the primary section to the secondary section. It is possible to move the secondary part about 1 to 2 cm back and forth with respect to the primary part. Movement is damped on both sides by internally mounted springs. Because this clearance is possible, the vibrations are damped in this way. The vibrations move in the space where there is play and are damped by the springs. The secondary part thus reacts slowly to the direct movements of the primary part.

When the gearbox of the car is removed, the condition of the flywheel can be checked. The play can be checked by moving the secondary part (on which the clutch pressure group is mounted) back and forth. If this clearance is too large (more than 2cm) or if there are noises, there is a good chance that the flywheel is worn out. The clearance has become too great and the vibrations are no longer properly damped. At present, the function of the dual mass flywheel can even counteract; the vibrations are amplified.