Subjects:

Torsional Vibrations

Vibration Damper

Torsional Vibrations:

The crankshaft is loaded in 2 ways; namely on bending and on torsion. The bending forces arise when a connecting rod is pressed down by a power stroke. The torsional forces arise because one part of the crankshaft wants to turn and the other part does not (torsion). When these torsional forces are removed, the crankshaft springs back to its original state. Force is thus exerted on the crankshaft by all pistons. A torsional vibration is not only dangerous at certain high rotational frequencies, but the vibration can also be amplified by a combustion force stronger than another (for example with a defective ignition coil).

Vibration Damper:

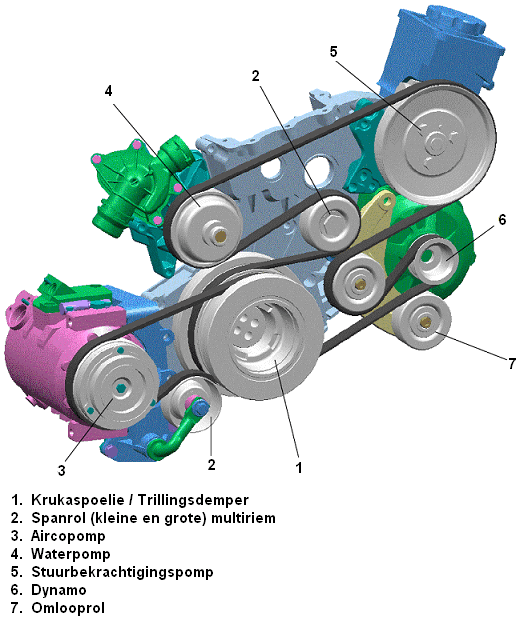

The vibration damper attached to the crankshaft is used to dampen the torsional vibrations as much as possible. This torsional vibration damper is also the multi-belt pulley, over which the multi-ribbed belt runs (see image below). The vibration damper consists of two metal parts with a rubber ring in between. One metal part is attached to the crankshaft and the other part acts as a flywheel. Due to the elasticity of the rubber in between, a certain amount of movement is possible. This has a braking effect on the vibration, so that it is damped. The vibration damper is not able to completely remove all vibrations, but it can limit them.

Related pages: