Subjects:

- Variable valve timing

- MultiAir

Variable valve timing:

The power of the motor is largely dependent on the camshaft. If it has cams that are long and oval, the valves open longer. So more air can get in and out of the engine, which produces more power. If the cams are shorter and more pointed, the valve will open less wide and close sooner, allowing less air to go in and out, so it will also deliver less power. The advantage is that it Fuel consumption can be reduced.

Low-load motor revs require:

- Intake valves open late and close early.

- Exhaust valves open late and close early.

High engine revs with high loads require:

- Open intake valves early and close late.

- Open exhaust valves early and close late.

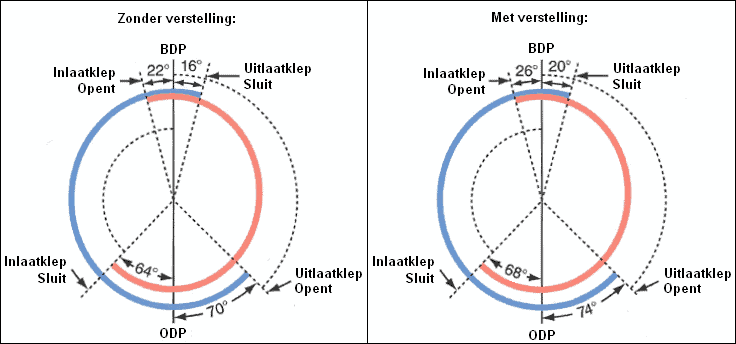

Car manufacturers always look for a middle ground. Variable valve timing adjusts the camshaft to the required position at the rpm the engine is running at. The figure shows two valve diagrams.

The left valve diagram shows the “normal” situation without adjustment, the right one after adjusting both the intake and exhaust camshafts. It can be seen that during the adjustment the inlet valve opens 4° earlier and closes 4° later. The exhaust valve also opens 4° earlier and closes 4° later.

Adjusting the camshafts:

With this form of variable valve timing, the camshaft rotates with respect to the gear that runs through the timing belt of timing chain is powered (see figure below). This system allows for earlier or later opening of the valves, but cannot control that the valves stay open longer, because the shape of the camshaft remains the same. The system shown below works hydraulically. The engine, including the camshaft sprocket, rotates clockwise. 2 positions are marked in the camshaft sprocket in the image below, where the camshaft will be in relation to the sprocket at rest (pink) and at full load (purple). Also marked on the cams themselves are the positions of early open at full load (purple) and neutral (pink).

In the situation of quiet driving, i.e. low revs with low load, the valves will open later. The pink markings then apply. When giving full throttle and accelerating hard, the purple part applies. Oil is then pumped to the adjustment point in the camshaft sprocket, causing the inner portion to rotate to the right. The camshaft is then turned with respect to the gear wheel, so that the cams will push the valves open and closed sooner.

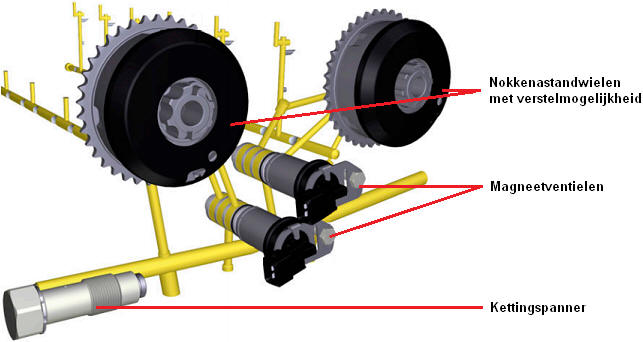

The illustration shows the oil chambers in the adjustable camshaft gears. By filling the space with oil, an adjustment of the camshaft takes place. The timing gears are rotated relative to the camshaft mounting.

The picture shows the two adjustable camshaft sprockets with the oil channels. The oil channels are colored yellow.

The oil pump in the sump provides oil pressure to the solenoid valves. When the solenoid valves are controlled by the engine control unit (the ECU), they transfer the oil pressure to the camshaft sprockets. The solenoid valves therefore ensure that the camshaft sprockets adjust.

Possible malfunctions in the above system include:

- Solenoid valves that no longer supply the camshaft sprockets with oil pressure. This is often a result of pollution. In that case, the strainer in the solenoid valve may be clogged with black sludge or other dirt particles. Cleaning often offers the solution.

- Camshaft sprockets that no longer adjust correctly. This is often also a result of pollution.

Pollution is usually caused by driving too long with old engine oil.

Multi Air:

MuliAir is a fully electronically controlled system for individually controlling the opening and closing of the inlet valves via an electronic-hydraulic control. With MultiAir, both the valve lift and the valve timing of the inlet valves are controlled. MultiAir is used on both petrol and diesel engines. An adjustable camshaft is no longer necessary.

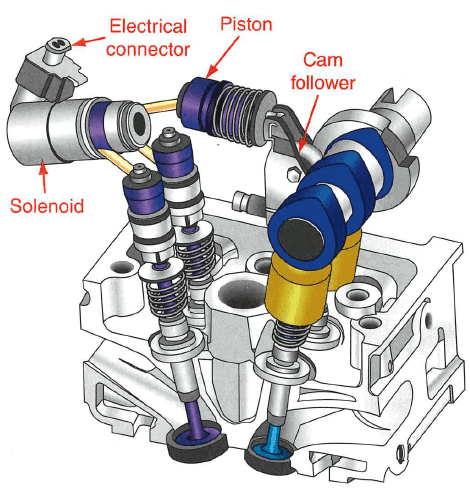

With MultiAir there is a hydraulic connection between the camshaft and the inlet valve. The camshaft drives the piston of the MultiAir high-pressure cylinder via a roller rocker arm. The piston in this high-pressure cylinder forces the oil to the electronically controlled valve; also called the solenoid or solenoid valve. The oil volume passed to the oil chamber above the inlet valves is varied by the electronically controlled valve. Less oil volume means that the intake valve opens less wide. This electronically controlled valve is precisely controlled by the engine control unit (the ECU). As a result, both the timing and the lift height can be precisely adapted to the air demand of the engine.

When engine power is required, such as when driving at higher speeds and with higher engine loads, the intake valve will open fully.

During engine starting and idling, the intake valve will open later. There will be a large underpressure in the combustion chamber, which causes the air speed to increase when the inlet valve is opened. This ensures better mixture formation and better combustion.

At medium revs and partial engine load, the intake valve will close earlier. This prevents interference in the intake manifold and reduces gas exchange losses, ultimately resulting in a higher engine torque.

There is also a “multilift” at medium speeds and partial engine load. With multilift, the exhaust valves are opened several times per power stroke, which improves the combustion quality.

MultiAir also makes it possible to briefly open the intake valves at the end of the exhaust stroke; this adds a small portion of the exhaust gases to the intake air and creates an internal EGR.