Subjects:

- General operation of the suspension system

- McPherson

- coil spring

- Spring constant

- leaf spring

- Air suspension

- torsion spring

- Hydropneumatic suspension

General operation of the suspension system:

The purpose of the suspension system is to absorb the movements of driving over unevenness in the road surface as well as possible, so that the most driving comfort is maintained. The road holding also affects the suspension. When the suspension is very flexible (think of old American cars) the road holding will be a lot worse than a car where the suspension is stiff. This is because a very smoothly springing car loses its grip when it rebounds (e.g. when braking hard or taking sharp bends). The pressure of the tires on the road surface is many times less with a wheel that is sprung than a wheel that is compressed and will therefore slide much faster. Also, when taking sharp bends at high speed, the chance of breaking out will become very great, because the grip of the tires on the inside of the bend is minimal.

When a very smoothly sprung car is driving over a hilly, paved road surface, the car will sway a lot when rebounding. When the car is fully suspended, the pressure on the tires is therefore less and there is little or no braking and steering at that time.

With a car with stiff suspension, especially sporty cars or lowered cars, the grip on all 4 wheels will be as maximum as possible when taking sharp turns. The stabilizer bar and tire size also have a major influence on this. When a lowered car drives over a hilly, paved road surface, the car will remain tight on the road and therefore experience no problems with sudden hard braking when the condition is extended.

The flexible and stiff suspension (on cars with coil springs) is a spring constant. In order to ensure optimum suspension of a car (depending on the construction), flexible springs for comfort (linear springs) or stiffer springs for sportiness (progressive springs) can be fitted. More about this in the Spring constant chapter, further down the page.

McPherson:

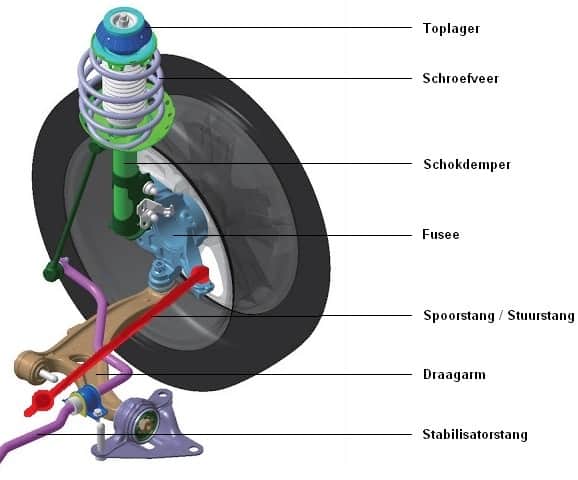

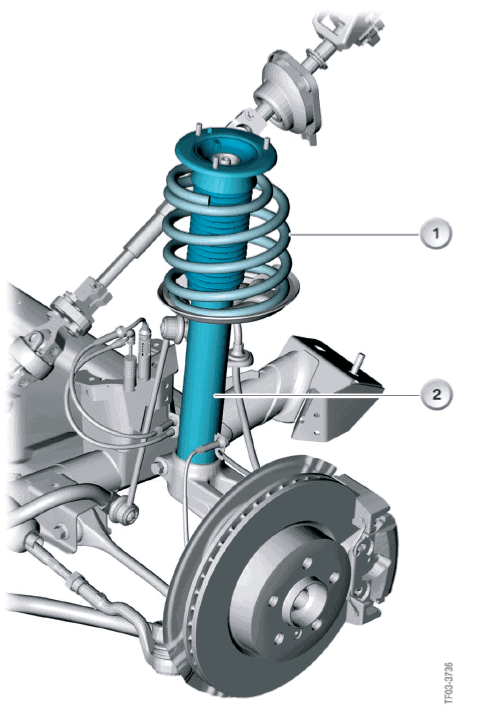

The big advantage of the McPherson wheel suspension is that the suspension and the shock absorber are combined. This saves a lot of space and is also easy to construct when designing the car. As a result, production costs are also low.

The McPherson wheel suspension is a further development of the wheel suspension with two transverse wishbones (also called a double wishbone construction). The upper wishbone is replaced by the piston rod of the shock absorber, which now also absorbs the lateral forces. Therefore, in the event of a collision with the wheel (by another vehicle or when driving against a curb), there is usually direct damage to the piston rod. This is because it deforms very quickly and is therefore curved. The complete shock absorber must then be replaced.

The McPherson wheel suspension is always applied at the front of the car. Suspension struts are sometimes also used at the rear axle, but these are not of the McPerson type. The coil springs and shock absorbers are often carried out separately on the rear wheel suspension.

The top bearing is located on top of the strut. The top bearing makes steering movements possible. The strut is often screwed to the body under the hood. So this is a fixed point. The top bearing, located underneath, ensures that the complete suspension strut can rotate smoothly with respect to the upper fixed point. This system with load-bearing function and a pivot with a top bearing is called the McPherson system.

Coil suspension:

The operation of a coil spring is not based on bending as you may first think, but on torsion (torsion). When the spring is compressed, the helical rod will be twisted. The entire vehicle weight is supported by the coil springs. The coil spring is locked between the top bearing and the lower spring seat. When the vehicle compresses, the top bearing will push the coil spring down. Because it twists, a counterforce is created. This counterforce is ultimately the resilient effect. The more counterforce exerted by the spring, the more powerful the spring is.

Spring constant:

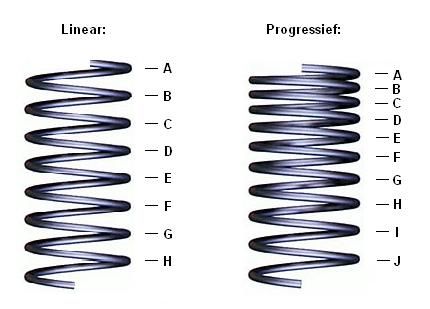

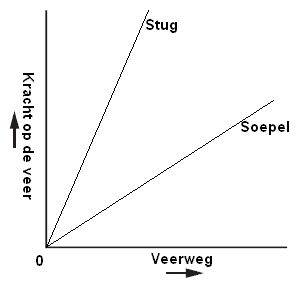

The flexibility of a spring is indicated by the spring constant. The spring rate of a linear coil spring is different from that of a progressive coil spring. In a linear spring, the distance between all turns is the same. With a progressive spring these distances are not equal; at the top or bottom of the spring, the turns will be closer together than elsewhere. The difference between these two types of springs can be seen in the picture:

With a linear spring, the spring always collapses a certain distance at a certain weight. The following is an example of the spring travel of a linear spring:

- + 100 kg extra load, the car sinks 2 cm.

- + 200 kg extra load, the car sinks 4 cm.

- + 300 kg extra load, the car sinks 6 cm.

There is now a relationship between weight and distance with this linear spring. The compression of a linear spring is shown below; the greater the force on the spring, the greater the spring travel. The lines are straight because the distance between all turns of the spring are equal.

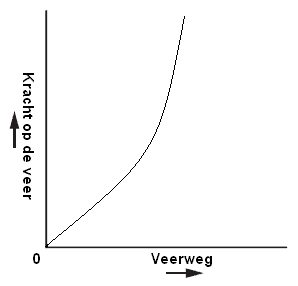

With a progressive spring there is no relationship between weight and distance. This spring becomes increasingly stiff as it compresses further. The first part is easy, but as the load increases, it springs less and less. This is because the windings are closer together at the top. The following is an example of the travel of a progressive spring:

- + 100 kg extra load, the car sinks 2 cm.

- + 200 kg extra load, the car sinks 3 cm.

- + 300 kg extra load, the car sinks 3,5 cm.

Below is the graph of a progressive spring. In the beginning, with increasing force of the spring, the spring travel will increase. The line is not dead straight, but slopes upwards. That is, as the force on the spring increases further, the spring travel decreases. The car will therefore deflect less and less as the force on the spring increases.

Car manufacturers are always looking for the best ratio between the comfort and the driving characteristics of the vehicle. By adjusting the progressiveness of the spring (by placing more or less turns close together) the travel can be adjusted. Also the diameter of the coil itself has a lot of influence on the amount of torque that is possible. This will be different for every car. Also of the same type of cars with a different cylinder capacity, type of engine (petrol or diesel), sports package, etc., there are all different types of springs.

Lowering springs often collapse a lot in the first part, so that the car is already lower above the road surface in the neutral position. This should make it more difficult to compress the car, so the springs are made extra progressive. Otherwise, the vehicle would hit the road way too quickly. Because the springs compress less easily, the vehicle becomes stiffer; this is unpleasant for some people.

leaf spring:

Leaf springs consist of several leaves that are mounted on top of each other. The top leaf is called the main leaf. The more blades a spring has, the stronger and stiffer it becomes. In the past they were sometimes mounted under passenger cars. The leaf spring then consisted of only a few leaves, sometimes even just the main leaf. They are still used in commercial vehicles, but they are of course a lot thicker. The center of the leaf springs are attached to the axle and the ends to the body or chassis. The resilient movement is obtained by deflecting the multiple blades in the middle of the total length.

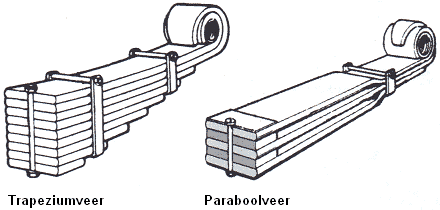

There are 2 different types of leaf springs:

- Trapezoidal spring: The spring leaves are of different length and they are all the same thickness throughout.

- Parabolic spring: The spring leaves are all the same length and are thicker in the middle than at the ends. There is also space between the spring leaves. Parabolic springs are more flexible than trapezoidal springs and have a smaller mass.

Air suspension:

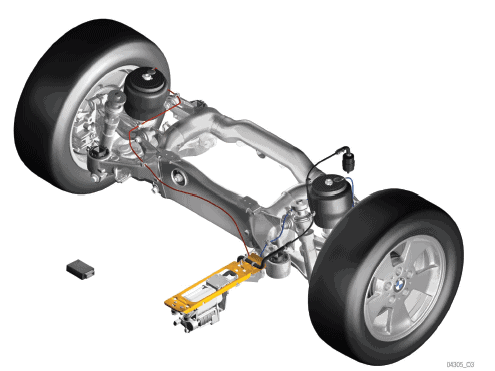

Air suspension is used less often than coil springs on passenger cars. For example, air suspension can be found on an Audi A8, BMW 7series or X5. These cars often have air suspension on all four wheels. Some cars have coil spring struts at the front and air suspension at the rear.

The picture shows a rear suspension with air bellows. In the interior of the car (often at the bottom of the trunk) there is a pump that pumps air into the air bellows. The air bellows expand lengthwise, so that the weight of the car can rest on them. Often there is a sensor on a wishbone, which registers how far the car has been sprung by the load (people sitting in the back, or a heavy trailer). Based on these measurement data, the air pump can inflate the air bellows a little harder, so that the car does not lean backwards.

Torsion Suspension:

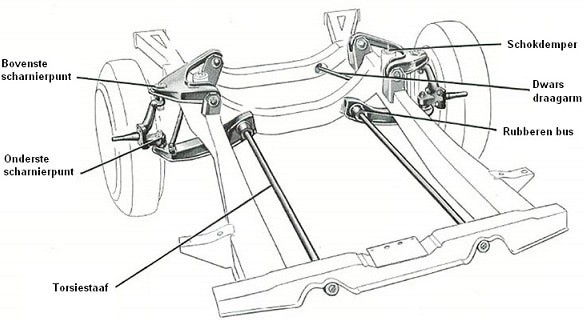

Torsion is another word for "twisting". Torsion springs used to be (mainly) applied to American cars. The lower wishbone of this construction is connected to the body by means of a torsion bar. When the vehicle sags, the top and bottom pivots will move. The wishbone in which the torsion bar is inserted will want to pivot around the torsion bar. However, that is not possible, because the torsion bar has a fixed connection in the support arm. The other side of the torsion bar (in the picture below) is firmly attached to the body.

This means that when the wheel compresses, the rod is subjected to torsion. This torsion builds up a resistance (the further the wheel compresses, the further the torsion bar is twisted). The compression therefore becomes heavier and heavier as the torsion increases. The entire suspension of the car's front axle works on this principle. That is also one of the reasons that the old American cars spring in and out so easily and smoothly.

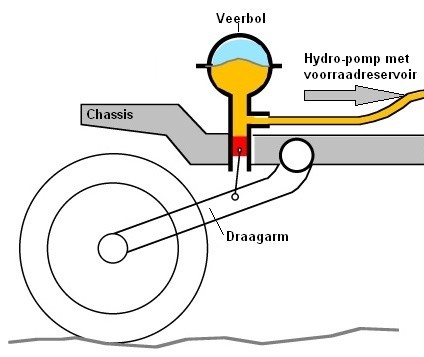

Hydropneumatic suspension:

Hydropneumatics is a combination of hydraulics and pneumatics. This system has been used by Citroën since the 50s and can still be found in the models today.

The spring bulb contains compressed gas (blue in the picture) that is compressible. The hydraulic fluid (yellow) is not. During compression, the red piston will be pushed upwards by the support arm and the gas space will be compressed. This makes the blue space smaller. When the wheel bounces back and the piston moves downwards, the system returns to its previous position. The resilient and damping effect is obtained by compressing this compressed gas.

The system can be controlled by adjusting the oil quantity (yellow). By adding extra oil in the system when heavily loaded, which is done automatically thanks to the hydro-pump, the ride height will increase. The vehicle will then stand higher on its springs. When the load is taken out again (or the passengers get out), the oil in the system will return to the storage reservoir via a pressure valve. The ride height will decrease again.