Subjects:

- Intake manifold

- Air pulses in the intake manifold

- Helmholtz resonator

- Intake manifold with swirl flaps

- Variable Length Intake Manifold

- DISA valve

- Exhaust manifold

Intake Manifold:

The intake manifold is mounted between the air filter intake pipe and the engine. The manifold tubes are mounted directly on the intake area of the engine, directly at the intake valves. In indirect injection petrol engines, the fuel injector is also mounted in the intake manifold. This injector injects the petrol fuel directly onto the inlet valve.

An intake manifold is not just a set of tubes. Its shape and finish should offer as little resistance as possible to the incoming air. All cylinders must receive the same amount of air. The inlet pipes should therefore be the same length for all cylinders. Usually the inlet manifold is made of plastic, because this is cheaper and less susceptible to heating due to high temperatures than, for example, metal. The air in the intake manifold should remain as cool as possible.

Air pulses in the intake manifold:

When the inlet valve is open, the air is drawn in at high speed. The airflow rate in the intake manifold is high. When the inlet valve closes, the air not yet admitted to the cylinder collides with the inlet valve and causes a pressure increase. This pressure increase thus causes a wave motion in the intake manifold, which moves against the airflow direction in the intake manifold. When the intake valve opens when the pressure wave returns, there is maximum cylinder filling; the pressure wave ensures that extra air enters the combustion chamber. However, this is almost never the case, because the engine speed varies and thus the intake valve almost never opens at the optimum moment for the pressure wave. With a longer intake manifold it will take less time for the pressure wave to reach the inlet valve again than with a short intake manifold. For this reason, it makes sense to be able to adapt the length of the intake manifold to the operating conditions of the engine (see the paragraph “Variable length intake manifold” or the use of a so-called Helmholtz resonator.

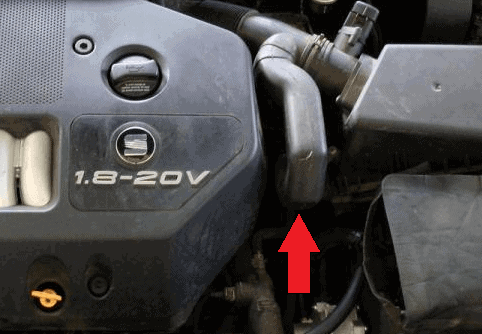

Helmholtz resonator:

A Helmholtz resonator is a resonance chamber that receives pressure waves caused by the closing of the inlet valve. The resonator is nothing more than a closed air chamber connected to the air intake hose between the air mass meter and the gas valve. An example of a Helmholtz resonator is indicated in the figure with a red arrow.

The pressure waves that enter the resonator are reflected back to the inlet valve. The pressure waves help the movement of the air inwards, so that a higher degree of filling is ultimately achieved. The resonator also ensures that the intake noise is muffled, so that the engine becomes quieter. The motor thus becomes more powerful and quieter.

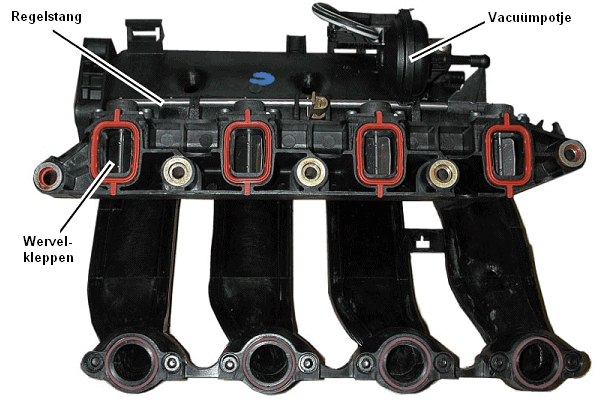

Intake manifold with swirl flaps:

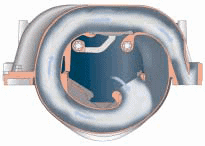

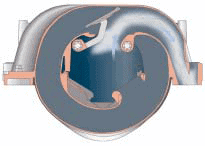

In diesel engines, intake manifolds with swirl valves are sometimes used. These valves ensure the swirling of the incoming air. At low revs, the air speed can be so low (because the turbo has not yet reached speed) that the vortex of the air is insufficient to get a good mixture with the diesel fuel. The injection pressure is independent of this. If the valves were not working, the mixture with the fuel, and therefore also the final combustion, would not be optimal. This has the consequence that the engine consumes extra fuel, produces less power and emits soot.

When the swirl valves need to be turned on, the vacuum cup is actuated, allowing the control rod to move from left to right. When moving the control rod, the valves can be set in the desired position.

Variable length intake manifold:

When constructing an engine, the length of the intake manifold ducts must be taken into account. The length of the inlet channels determines the pressure pulses that occur when the inlet valve opens and closes (see the section on air pulses). When these intake ducts are always long, the engine has high torque at low revs, but the pulling power is progressively reduced at high revs. And vice versa, if these are always too short, the engine will only have sufficient torque and power at a higher speed. By using a variable intake manifold, the length is adjusted according to the driving conditions. Here are the 2 situations:

- Long suction tube: Traveling the air a longer distance and making the diameter of the tube smaller gives the air a higher velocity. This is very beneficial at a high speed with a low load, or a low speed with a high load (more torque).

- Short suction tube: The air now travels a shorter distance and gives better cylinder filling at low RPM with low load and high RPM with high load (more power).

DISA valve:

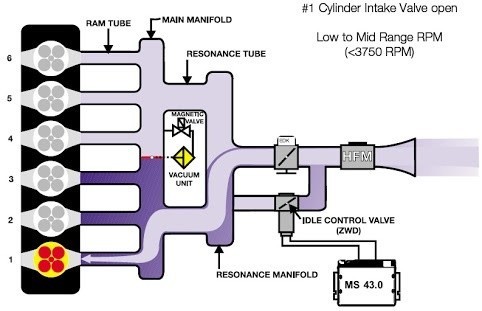

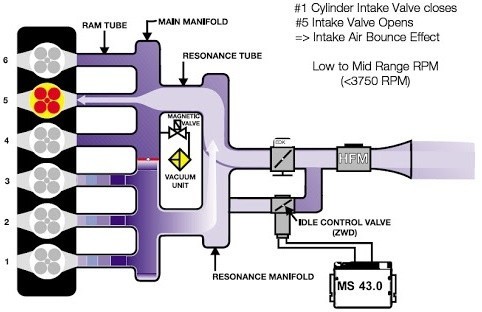

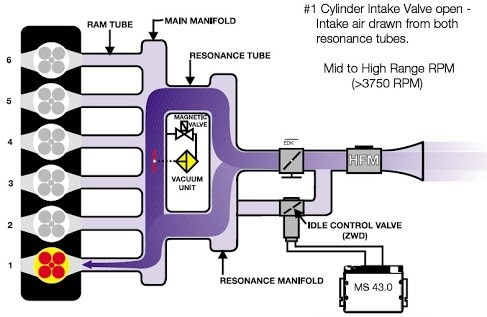

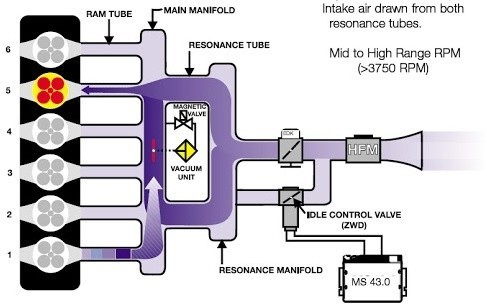

The DISA valve can be found in BMW's intake manifolds. DISA stands for: Differenzierte SaugAnlage. The DISA valve ensures that the airflow can be blocked at certain speeds in different parts of the intake manifold. This splits the intake manifold into two parts. Below is an explanation with three images.

At low or medium speeds, the DISA valve is closed. Air flows directly from the throttle body to cylinder 1. By directing the intake air through one section of the manifold to the intake valve, a higher air velocity is created. With this higher air speed, the air starts to swirl and a better mixing with the injected fuel is possible.

When the inlet valves of cylinder 1 are closed, a pressure wave is created. Because the valve is closed, the pressure wave will have to travel a long way through the resonance tubes to flow to the inlet valves of cylinder 5. The pressure wave will now have no influence on the air flow of the sucked air through cylinder 5.

At higher engine speeds, the DISA valve opens. Because the inlet length is now extended, more power is obtained at higher speeds.

The sucked in air flows through both resonance chambers. The rebound of the air after closing the inlet valve of cylinder 1 propels the air flowing to cylinder 5; the degree of filling of cylinder 5 is thus increased.

Exhaust manifold:

Also the exhaust manifold is not just a set of pipes. The faster the exhaust gases can flow out, the better. It's not just a matter of flow resistance. After all, the opening and closing of the exhaust valves must also be taken into account.

Example: A four-cylinder has a firing order of 1-2-4-3. When the exhaust valve of the second cylinder opens, that of the first cylinder is still open. Because the exhaust period of cylinder 2 is just beginning, the gas flows out at a greater pressure than it does at 1.

If the manifold is not the correct shape and diameter then the exhaust gases will have interference problems. The exhaust gases from cylinder 1 can counteract those from cylinder 2. However, with proper construction the reverse occurs and the gases from cylinder 1 help to extract the remaining exhaust gases from cylinder 2. This is especially the case with a so-called Spaghetti manifold (in the image below).

Some petrol and most diesel engines still have one exhaust gas turbo mounted on the manifold. This is mounted in the manifold as close as possible after the bend, in order to slow down the outflowing air as little as possible.

The hellish noise of an engine without mufflers is caused by the exhaust gases flowing out at great pressure and speed causing the air to vibrate. A muffler should reduce this pressure and speed.