Subjects:

- Purpose of the secondary air pump

- Operation of the secondary air pump

Purpose of the secondary air pump:

A petrol engine always has a rich mixture at a cold start. That means there is an excess of fuel, so less oxygen. Because the catalytic converter is not yet at working temperature during a cold start, it will not yet clean the exhaust gases. This means that the cold start leads to the emission of a large amount of carbon monoxide (CO) and unburned hydrocarbons (HC). The purpose of the secondary air pump is to allow the catalytic converter to heat up faster.

With a secondary air pump, outside air is added in the exhaust path. The extra air is led into the exhaust before the catalytic converter. Adding the extra air leads to an exothermic reaction. Exothermic means that heat is generated because the CO and HC components present burn the moment they come into contact with the additional air supplied. This raises the exhaust gas temperature. Due to the higher exhaust gas temperature, the catalytic converter will also heat up quickly, so that the harmful components in the exhaust gases can be removed as quickly as possible during a cold start. Worden reduced.

Operation of the secondary air pump:

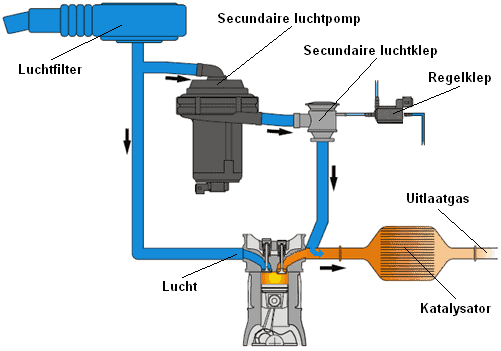

The secondary air system is located between the air filter and the exhaust. There is a branch to the secondary air pump on the suction tube from the air filter. An air hose runs from the secondary air pump to the secondary air valve. This air valve is only open when the engine is cold and the air pump is working. When the air pump is switched off, the air valve is closed, otherwise the exhaust gases can flow to the air pump. The opening and closing of the air valve is pneumatically (with vacuum) controlled by the control valve, which is controlled by the engine's ECU.

The outside air is fed directly to the exhaust gas. The exhaust gas will immediately heat up in the exhaust. As a result, the catalyst reaches its working temperature within a short time (from 250° Celsius). You can hear it when the air pump is running. The sound is often reminiscent of a vacuum cleaner. The pump often switches off again between 20 and 30 seconds after the cold start, because the catalytic converter has already warmed up sufficiently.

The additional air supplied is recognized by the lambda sensors. In the event of a defect in the secondary air system, such as a clamping air valve or leakage in the hoses, the lambda sensors will measure the deviation. The engine management will illuminate the emissions light on the dashboard. After all, in the event of a defect in the secondary air system, more harmful substances are emitted. A defect in the secondary air system will not affect the operation of the engine.

In addition to the secondary air system, the exhaust gas recirculation system (EGR) for exhaust gas aftertreatment.