Subjects:

- Parking brake

- Drum brake as parking brake

- Disc brake as parking brake

- Combination of disc brake and drum brake

- Electromechanical parking brake with electric motor on the caliper

- Electromechanical parking brake with brake cables to the electric motor

Parking brake:

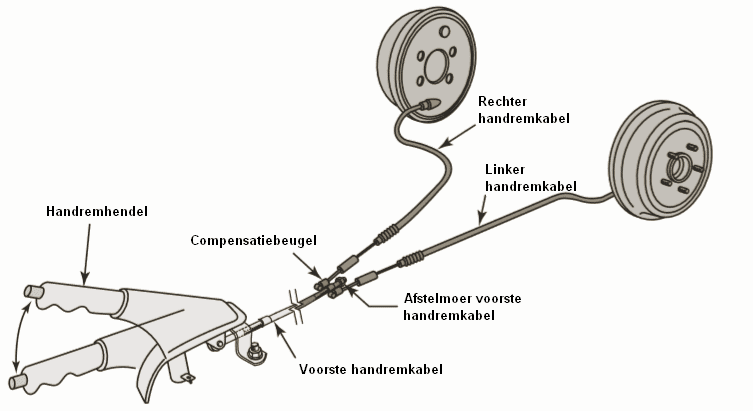

The parking brake is often referred to as the “handbrake” because many cars require the lever to be pulled by hand. The image below shows the parking brake with a handbrake lever, brake cables and drum brakes. When the operator moves the parking brake lever up, an internal mechanism locks the lever and holds it up. When the lever is operated, the front parking brake cable is applied. The left and right handbrake cables are connected to the front handbrake cable by means of a compensation bracket. The compensation bracket makes it possible to absorb the play; think of one stretched handbrake cable or an incorrectly adjusted mechanism in the brake drum. For this reason, if one cable is longer than the other, the compensation bracket will become skewed. However, both brake cables will be equally tightened when operating the parking brake lever.

The front parking brake cable is connected to the compensation bracket by means of an adjusting nut. We can twist this adjusting nut for the following reasons:

- Adjust handbrake. This may be necessary if, for example, the parking brake lever has to be pulled up eight notches before the brakes are locked.

- Dismantling of handbrake cables, handbrake mechanism in brake drums or brake caliper. The disassembly of certain parts without slackening the cables is often not possible.

The above explanation refers to the common cable operated parking brake. Nowadays there are also other versions, such as parking brake cables that are operated with the foot and the electric parking brake. This page describes the different versions of the parking brake.

Drum brake as parking brake:

When a car is equipped with drum brakes on the rear axle, a parking brake mechanism is built in here. When pulling the handbrake cable (see the red arrow to the left of the cable), the dark blue lever in the illustration at the bottom is pulled to the left. The lever pivots in the right (light blue) brake segment and pushes the brake lining against the (yellow) brake drum.

The white spacer is connected to the dark blue lever and the left (light blue) brake segment. The movement of the lever is passed on to this, so that the brake lining of this brake segment is also pressed against the brake drum.

When releasing the parking brake cable, push on the parking brake cable, spring the inner cable back into its initial position. The springs the brake segments pull the brake segments and the linings back together again, so that the brake linings come off the brake drum.

Due to wear of the brake drum, the diameter on the inside becomes slightly larger. The brake segments thereby move further out to contact the brake drum. For maintenance and repairs we have to remove the brake drum from the axle. Dismantling the drum is in most cases not possible without resetting the brake segments.

The mechanism contains a knurled wheel or catch that must be turned back or moved with a flat head screwdriver. The illustration shows the movement of the screwdriver to turn the knurled wheel. Turning the knurled wheel to one side causes the segments to move toward each other; the spacer becomes smaller and the springs of the brake segments pull the segments together. As soon as the knurled wheel has turned back far enough, the brake drum can be released.

When mounting, we must of course turn the knurled wheel the other way, so that the segments are in the correct position again.

Disc brake as parking brake:

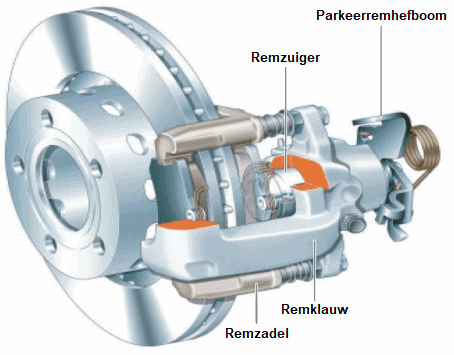

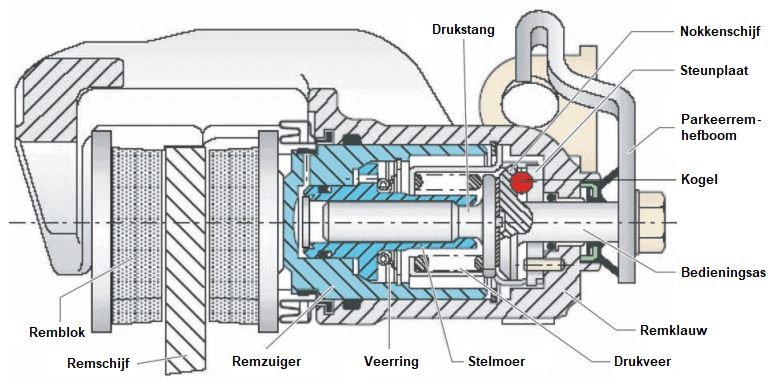

A vehicle equipped with rear disc brakes may be equipped with a parking brake mechanism. The following image shows the brake caliper with the parking brake lever. The lever is connected by a cable to the parking brake lever in the passenger compartment. When the driver operates the lever, the lever on the caliper will twist and internally move a mechanism. The parking brake uses the same brake piston as the service brake, which is actuated by the hydraulic brake circuit. During the actuation of the brake, the brake piston presses the inner brake pad against the brake disc. The “floating caliper” is pulled towards the side of the brake piston due to the guide pins, so that the outer brake pad is also pulled against the brake disc.

Read more about the disc brake.

When the parking brake is applied, the parking brake lever is turned via the brake cable. The control shaft and cam disc are connected to the lever and will rotate with it. In addition, this operating shaft makes a lateral stroke that ensures that the brake pad is pressed against the brake disc. The lateral stroke movement arises because the cam disc rotates along three balls with the increasingly thicker part during rotation. When the driver applies the parking brake even more forcefully, the cam disc will push the push rod out even further.

The adjusting nut and compression spring have the task of absorbing the wear of the brake pads. With wear, the brake linings become thinner and the adjusting nut will absorb this play as a “self-adjusting mechanism”. For this reason, when replacing the brake pads, the brake piston must be turned back with a special reset tool.

Combination of disc brake and drum brake:

The paragraphs above describe two different types of brake systems: the drum brake and disc brake. The service brake (which is hydraulically actuated with the foot brake pedal) is combined with a parking brake mechanism in these versions.

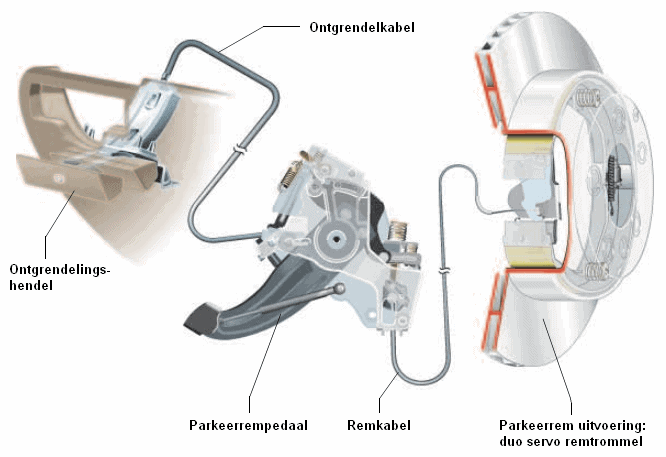

A number of car manufacturers (including BMW and Opel) combine these braking systems on the rear axle. The brake disc serves as a service brake. The inner side of the brake disc acts as a brake drum for the parking brake. This can be clearly seen in the picture on the brake segments. The brake cable operates the mechanism of the drum brake to slow down or slow down the brake disc. to block.

In addition, an alternative operating mechanism can be seen. The driver applies the parking brake by depressing the parking brake pedal. This pedal is located on the far left of the A-pillar.

When the parking brake pedal is operated, a locking mechanism ensures that the pedal remains depressed. Pressing the pedal more forcefully causes it to move down with more “clicks” and locks the parking brake more forcefully.

To release the parking brake, the driver must pull the release lever. The lever is connected with the release cable to the mechanism behind the parking brake pedal. The parking brake will immediately fully release and the pedal will shoot back up to its fullest position.

A similar mechanism can also be designed without the release lever. For example, Toyota and vehicles from American manufacturers are equipped with a parking brake pedal with automatic release. With active parking brake, the driver can unlock the mechanism again by pressing the pedal again.

Electromechanical parking brake with electric motor on the caliper:

Vehicles may be equipped with an electromechanical parking brake. The driver can operate the electric motor on the rear brake calipers with a button on the dashboard. In addition, the vehicle can also actuate the parking brake mechanism when standing still on a hill. This function is called “hill hold”. The ECU automatically applies the parking brake when you stop and drive off, so that the vehicle does not roll away. The driver can take his or her foot off the brake pedal.

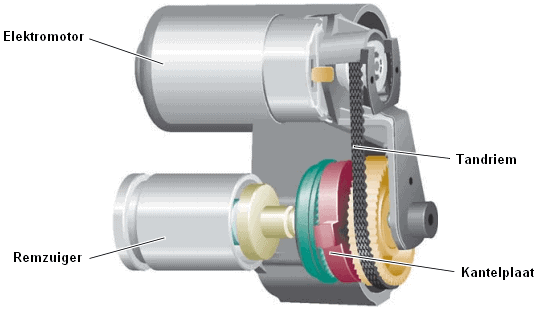

The rear brake calipers are equipped with an electromechanical mechanism that transfers the rotation of the electric motor to the brake piston.

The electric motor drives the gear wheel that is connected to a tilting plate by means of a toothed belt transmission. A spindle is attached to the tilting plate. The spindle is basically a worm gear that can rotate left or right; this depends on which direction the electric motor turns. A large spindle nut is twisted on the spindle; the spindle nut presses against the inside of the brake piston. Twisting the spindle will cause the spindle nut to move in or out.

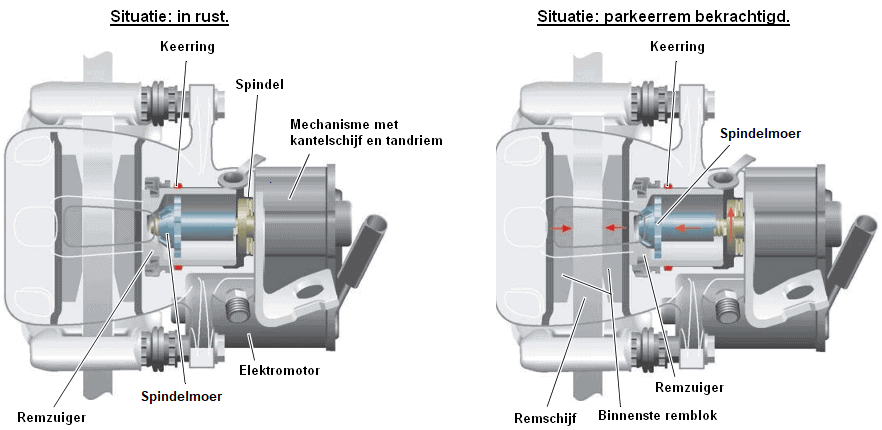

The images below show the electric parking brake at rest (left) and engaged (right). The spindle is twisted, causing the spindle nut to push the brake piston against the brake pad. Because a floating caliper is used, both brake pads are pushed against the brake disc. The brake is blocked in this situation.

As soon as the parking brake is released, the electric motor drives the spindle through the mechanism to allow the spindle nut to rotate back in. The spindle nut does not pull the brake piston in; these parts are not attached to each other. The brake piston is pulled back into its rest position by the deformed seal ring.

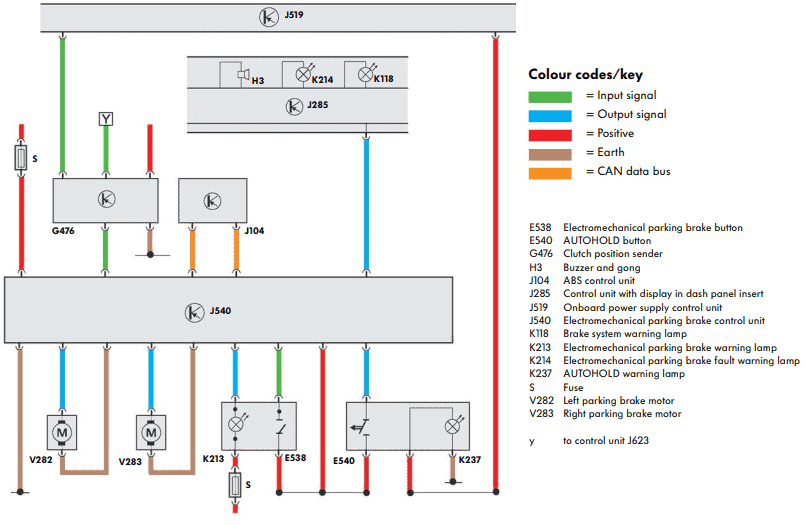

In most cases, the parking brake is operated manually by pressing a button on the dashboard, or via an automatic control as soon as the ignition is switched off. The diagram below shows the electrical components of the VW Passat 3C.

The parking brake control unit (J540) receives a signal via the parking brake switch (E538) when actuated by the driver. In that case, the power wire at the bottom of the internal switch (red) is connected to the signal terminal of the control unit (green wire). As soon as the ECU detects a supply voltage on this connection, it knows that the switch has been operated.

The control unit supplies the electric motors of the brake calipers with a power supply. In the schematic these wires are shown in blue and brown. The polarity can be reversed to make the motors run in the other direction.

In addition to the parking brake switch signal, the parking brake control unit (J540) also receives information from other components:

- ABS computer (J104) to report vehicle speed. The parking brake cannot be operated or can be operated to a limited extent while driving. The parking brake can also offer a solution in the event of an emergency stop and the autohold function.

- clutch position sensor (G476): The driver must depress the clutch pedal to release the parking brake.

- Autohold switch (E540): If the vehicle is equipped with autohold, the parking brake automatically engages when standing still on a hill. For this function, among other things, the signals from the ABS computer and the angle of inclination detection are used.

The parking brake control unit provides the instrument panel (J285) with information to control the indicator/error lamp and buzzer.

Electromechanical parking brake with brake cables to the electric motor:

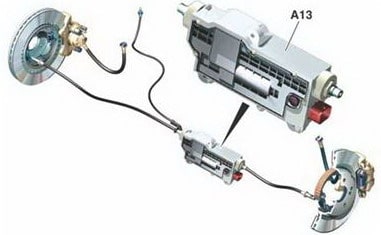

In another version of the electromechanical parking brake, no electric motors are mounted on the brake callipers, but one centrally on the body, at the height of the rear axle.

The parking brake actuator is connected to the brake calipers by brake cables. In this respect, the system therefore has similarities with a manually operated parking brake.

The driver operates this actuator by pressing the button on the dashboard. The parking brake control unit engages the electric motor to apply or release the parking brake cables.

When parking on a slope, an automatic control controls the actuator so that the vehicle cannot roll away.

Related pages: