Subjects:

- Lubrication System

- Engine oil level

- Function of lubricating oil

- Properties of lubricating oil

- dopes

- Contamination of the lubrication system (including sludge)

- Consequences of driving too long with contaminated engine oil

- SAE Specifications (Viscosity / Viscosity Index)

- ACEA Specifications

- API Specifications

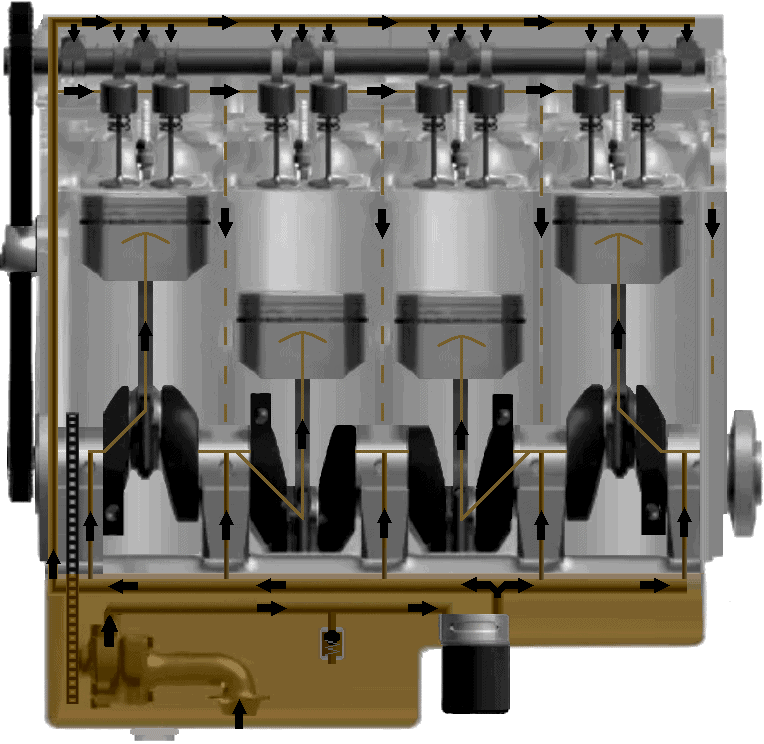

Lubrication system:

The lubrication system ensures that the engine oil is pumped and filtered throughout the engine. Because there is a lot to tell about this, the topics “oil” and “lubrication system” are separated. On the current page everything about engine oil is explained, and the construction and operation of the lubrication system is explained on the page lubrication system.

Engine oil level:

The importance of the engine oil level is often underestimated. The level should not be too high or too low.

Many people forget to check their oil level regularly. Certainly if the cars are not equipped with an electronic oil level sensor, there is a danger that the oil level will fall far below the minimum before action is taken.

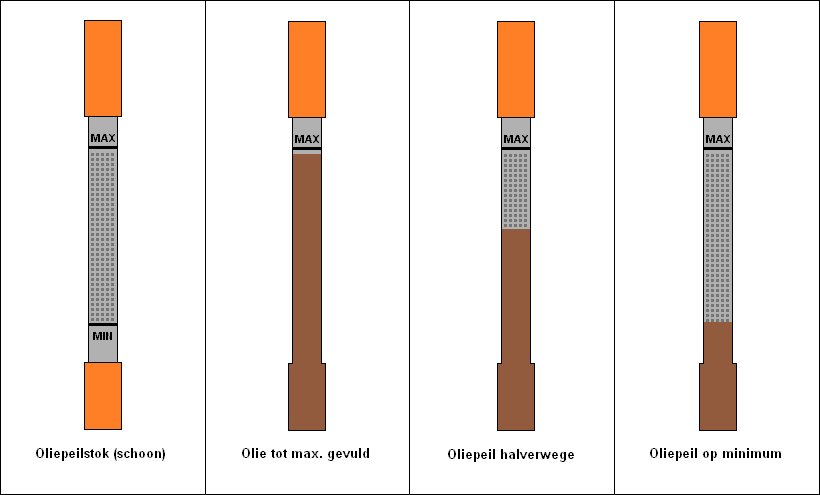

The ideal situation is when the oil level is at max. (second dipstick from the left in the picture).

If the oil level is at minimum (fourth dipstick), often half or a whole liter needs to be topped up. Then first top up with half a liter and, after checking, top up the oil until it is at max. When the oil level is halfway (third dipstick), in principle nothing needs to be topped up. It is, of course, best to do so.

If the oil level is minimal, it does not necessarily mean that it is bad for the engine. It is the minimum level at which the engine can run. During the design and testing of the motor, the rotating test motor is tilted at all possible angles, which can also occur in practice. Under no circumstances should the oil screen run dry and the lubrication system must not be endangered. The minimum oil level is determined with this data.

A minimal oil level does ensure faster aging of the oil in the engine. The same oil has to take over all the tasks that would normally happen with more oil. The oil heats up faster and the lubricating properties deteriorate sooner. So it is best to keep the level at or near the maximum mark on the dipstick.

If the oil level is less than minimal, or even not even visible on the dipstick, add oil immediately to prevent engine damage.

An oil level that is too high is also not good. From half a liter too much oil (above max.) the crankcase pressure can increase. More oil can then end up in the combustion chamber (via the crankcase breather in the intake manifold, or along the pistons via the cylinder wall upwards). In the latter case, it is more than a liter too much oil. If the oil level is too high, the catalytic converter can therefore be damaged. Due to an increased crankcase pressure, (unburned) oil flows past the piston rings, through the combustion chamber and into the catalytic converter, which immediately adheres to the interior. This can cause it to fail prematurely. The oil deposit that adheres to the interior of the catalytic converter cannot be undone.

One or two millimeters above max. is not harmful. However, if the level is higher than this, a part must be drained or extracted.

Function of lubricating oil:

Engine parts that move past each other must be lubricated. The lubrication system supplies the parts that move relative to each other with lubricating oil. Engine life is largely dependent on the quality of the oil. That is why it must also be refreshed periodically. Always replace the oil filter when changing.

Lubricating oil has the following functions:

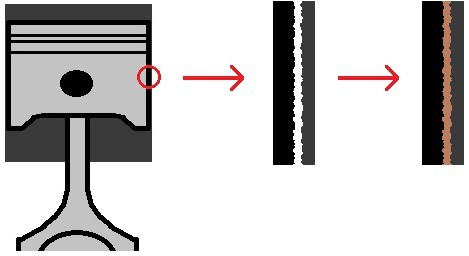

- Lubricate: The oil should prevent metal-to-metal contact. The oil forms as a layer between the parts, which limits the friction and thus also the wear. The picture shows a piston in a cylinder. If the piston or the cylinder wall is felt, it seems that it is completely smooth. If the part that is circled is greatly enlarged under a microscope, it becomes visible that this is not the case. This can be seen after the first red arrow.

- cooling: Parts such as valve guides, pistons, cylinder walls, etc. partially dissipate their heat via the lubricating oil.

- Sealing: The piston in the cylinder is sealed gas-tight by means of the oil. The oil therefore also contributes a large part to the compression.

- Clean: Dirt and wear particles that are released are discharged by the oil to the filter.

- sound dampening: Due to the oil film between metal parts, the metal noise is also partly muffled.

- Power transmission: The oil must also be able to transfer forces, eg in the hydraulic valve lifters. A certain pressure is built up in a valve lifter, in which the oil must not be compressed.

Both the piston material and the cylinder wall contain small irregularities. These imperfections are inevitable, no matter how well the material is worked. When these unevennesses interlock, which happens when there is no oil film present, friction is created. The irregularities will rub against each other.

By applying an oil film (the right part) the rough parts are pushed apart by the engine oil. The parts will not touch each other and the heat that is released is dissipated through this oil film to the rest of the engine oil. This oil film also provides a seal, so that as little combustion gases as possible can enter the crankcase from the combustion chamber above the piston.

Properties of lubricating oil:

- Animal oil: This oil is obtained by boiling, extraction or pressing of bones (ox leg oil) and animal fat. Animal oil is added to mineral oils and is no longer used as a full lubricant.

- Vegetable oil: This oil is made from plants. Vegetable oils are also known as fatty oils. They have good lubricating properties, because they adhere well to the material. Vegetable oils have the disadvantage that they age very quickly due to the oxygen in the air. They are therefore not suitable for long-term use. The oxidized oil thickens and contaminates the parts to be lubricated.

- Mineral oil: The raw material of mineral oil is crude petroleum, which consists of various compounds of hydrocarbon and hydrogen. The advantages of mineral oils are that they are cheaper and they age less quickly than animal and vegetable oils. The disadvantage is that mineral oils adhere less well to metal.

- Compound oil: This is a composition of mineral oil with 5 to 20% vegetable or animal oil. The addition of the other oils improves the adhesion to the metal. Compound oils easily absorb water and age faster than mineral oil.

- Synthetic Oil: This oil is laboratory manufactured. This oil is created by combining small molecules into large molecules.

Advantages of synthetic oil:

- Low viscosity (so less frictional resistance)

- More resistant to oxidation

- Less sensitive to high temperatures

- Natural cleansing effect (detergent)

drugs:

Dopes are also added to synthetic lube oils, such as:

- Detergent dopes act like a dirt remover; dirt particles loosen from internal engine parts and are discharged to the oil filter.

- Anti-oxidation dopes prevent oxidation. Oxidation means attack by oxygen. As the oil oxidizes, the oil ages and thickens, making it more difficult to pump. Therefore, synthetic oil with these anti-oxidation dopes will have a much longer useful life than cheap mineral oil.

- Anti-wear caps counteract the wear. One dope prevents wear at high temperatures, the other at low temperatures).

- Viscosity index improving dopes ensure that temperature has less influence on the viscosity of the oil. Engine oils with viscosity index improving dopes are called multigrade oils.

The dopes wear off as the engine oil ages. If the service intervals are exceeded and the same oil is used for too long between turns, the dopes will almost be ineffective. The engine will become dirty internally, because the oil will no longer soak the dirt from the parts. It is therefore very important to refresh on time. See the paragraph “Consequences of driving too long with contaminated engine oil”.

Contamination of the lubrication system (including sludge):

Engine oil becomes contaminated after a certain time, due to combustion products, fuel particles and wear particles. Because the oil is contaminated, it must be changed after a certain time. If you drive for too long with outdated oil, or if the wrong oil is in the engine, the lubrication system can become heavily contaminated, and significantly more engine wear occurs. The oil slowly turns into a kind of sludge. This sludge is also called 'sludge'. There are 2 types of sludge:

White/grey sludge:

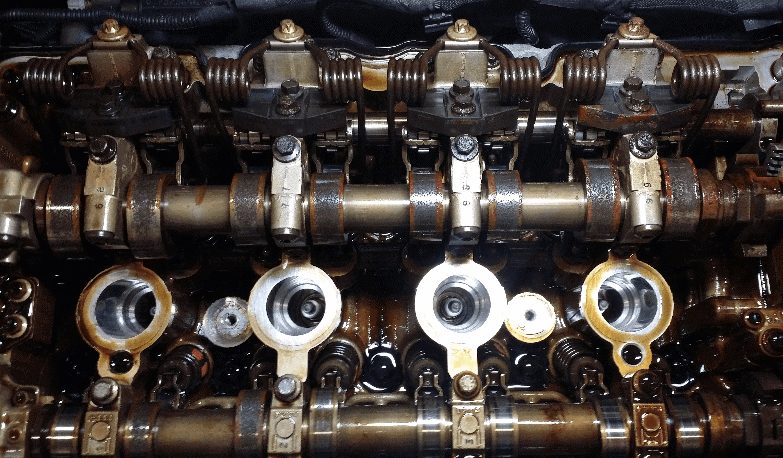

This sludge is a mixture of water vapor and oil. This occurs during many short trips, where the oil does not heat up properly. It settles on the still cold parts of the engine (usually the valve cover or crankcase ventilation hoses). It can often be seen when the oil cap is removed (see picture).

If there is this kind of sludge in the engine, it is wise to drive for a long time and the engine warms up sufficiently that the sludge disappears automatically. It is best to also change the oil. There may be a lot of sludge in the engine, as shown in the image below. This is the underside of a disassembled valve cover of a Mini. Many short trips have been driven with this car, so that the oil has almost never warmed up properly. By flushing the motor with special motor flush (available in many different types) and then changing it several times (flushing), a large part of this sludge can be dissolved. However, it is better to remove the valve cover, as this is usually the coldest part of the engine and will contain the most sludge. Do not forget to check the crankcase ventilation hoses, because there will undoubtedly also be sludge in them.

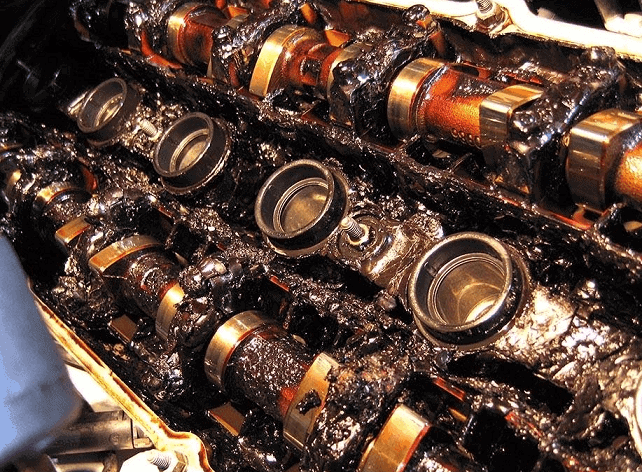

When the sludge is present in the engine for a long time, the moisture in this sludge can cause damage to the engine parts. Below is a photo of the camshafts from the same Mini from which the valve cover was removed. Especially of the intake camshaft (the top one in the photo) the coating is very affected by moisture. The exhaust camshaft looks better, but it also has significant damage on a number of cams.

black sludge:

This sludge is very bad for the engine. It is a black, sticky hard layer that deposits on internal parts of the engine. In the photo below black sludge is visible.

There is a danger that the lubricating oil channels and the oil screen will become clogged, so that the oil can no longer be pumped properly. This form of sludge is caused by: driving in traffic jams, driving short distances, setting the fuel system too rich (carburetor), poor crankcase ventilation, too high combustion temperatures in combination with very old engine oil that has not been changed in time.

Black sludge can be removed while the 'drab' is still soft. When a minimal amount of sludge is discovered, the oil should be changed immediately and the filter replaced. If the sludge has been in the engine for longer and is completely caked, it is very difficult (by means of engine cleaning agents and disassembly/assembly of parts such as sump pan, oil strainer, etc.) or in the worst case impossible to remove from lubrication channels at all.

Consequences of driving too long with contaminated engine oil:

Today, car manufacturers set the drain interval at max. 30.000 km or 2 years. Sometimes that is too long and the engine oil has been contaminated for a long time before changing. Outdated (or poor quality) oil causes black sludge (described above). Moisture will also penetrate into the engine oil, and it will become acidic due to, among other things, the combustion gases. Oil attracts moisture; so when a car stands still for a year, it is not the case that the engine oil is not outdated that year. The oil has attracted moisture and has formed a bond with oxygen (which causes it to thicken). In principle, the oil will have to be changed, because the lubricating effect will no longer be guaranteed.

When driving many short distances, or when the car is not used often, it is sometimes wise to shorten the maintenance intervals to 15.000 to 20.000 km instead of 30.000 km. According to research, more than half of 4 to 6 year old cars drive with bad oil. Even when serviced every 30.000km or 2 years. Driving longer with the oil to save costs is even worse. Oil that has been around for so long has already largely lost its lubricating effect and the active dopes. The oil therefore no longer absorbs dirt. The engine will therefore become dirty internally and wear out faster. And that entails the necessary repair costs, such as stuck piston rings, worn camshafts, or a defective turbo. Also, an engine with 200.000 km that has been running for far too long with old oil will have the same wear and tear as an engine that has run more than 400.000 km with good oil. That is why it is unwise to save on fresh engine oil.

Always replace the oil when changing the oil oil filter.

This also applies to the (automatic) transmission oil. This is often referred to as “life time” oil; oil that does not need to be changed. However, this oil also acidified and polluted. That happens with any oil. That is why the transmission oil will also have to be changed periodically.

SAE Specifications (Viscosity / Viscosity Index)

The SAE specification specifies the oil's viscosity (thickness). Viscosity is the thickness of the oil at a given temperature. A thick oil has a high viscosity and a thin oil has a low viscosity. The viscosity therefore depends on the temperature. Oil has been tested at different temperatures, allowing the viscosity index to be determined. The viscosity index coding is always indicated on the packaging, eg 5W30 or 10W40. The letter before the W indicates the viscosity at low temperatures and the letter after the W indicates the viscosity at high temperatures.

Oil of too low a viscosity can be a cause of an oil pressure that is too low. The thin oil is pressed through the channels too easily, so that there is no good pressure build-up.

Oil consumption can also increase with too low a viscosity; because the oil can more easily enter the combustion chamber via the piston rings and thin oil can evaporate sooner, after which those vapors enter the combustion chamber via the crankcase ventilation system.

The viscosity index of the engine oil cannot be compared with that of the transmission oil. For example, the viscosity index of transmission oil is often 75W90. That does not mean that this oil is thicker than the 10W40 of the motor oil. It should be seen as a ratio. If the transmission oil were to specification 10W40, it could also be mistaken as engine oil by an inattentive person. Because the numbers now differ so much from each other, this can be seen quickly for an observant person.

ACEA Specifications (European)

ACEA specifications are tailored to European driving and usage conditions. ACEA specifications are the former CCMC specifications (CCMC was changed to ACEA in 1990). There are ACEA specifications for:

- petrol engines

- light diesel engines (light duty diesel engines) with a max. speed of more than 3500 rpm. for both direct and indirect injection.

- heavy-duty diesel engines refers to slow-running, direct-injection diesel engines.

Gasoline engines: | Light diesel engines: | Heavy diesel engines: |

ACEA A1-96 | ACEA B1-96 | ACEA E1-96 |

ACEA A2-96 | ACEA B2-96 | ACEA E2-96 |

ACEA A3-96 | ACEA B3-96 | ACEA E3-96 |

|

| TD-4 |

API Specifications (US)

The API specifications are tailored to US driving and usage conditions. The API specifications distinguish between gasoline and diesel engine oils.

- Specifications for the petrol engine:

SC, SD, SE, SF, SG, SH and SJ - Specifications for the diesel engine:

CC, CD, CE, CF-4 and CG-4

The S indicates that it is oil for the petrol engine, the letter C for oil for the diesel. The 2nd letter indicates the quality. The higher the letter after the S or the C, the higher the quality requirements.