Subjects:

- Measuring cylinder head and engine block flatness

Measuring the flatness of the cylinder head and engine block:

After dismantling a cylinder head, the flatness must be determined. There is a possibility that the cylinder head may be warped after the engine has been overheated once. When the bent cylinder head is reassembled, complaints regarding leakage of the head gasket may occur. In addition to the cylinder head, the rotating part of the engine should also be checked in the same way. In the event that we observe too great a deviation, in most cases machining operations are possible to reassemble the cylinder head without any problems. The requirements for measuring the flatness are:

- clean measuring surface of both the cylinder head and the engine block;

- steel straight;

- feeler buddies.

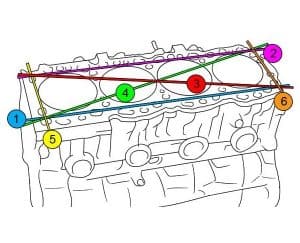

The following figure shows a measurement on the surface between cylinders 2 and 3.

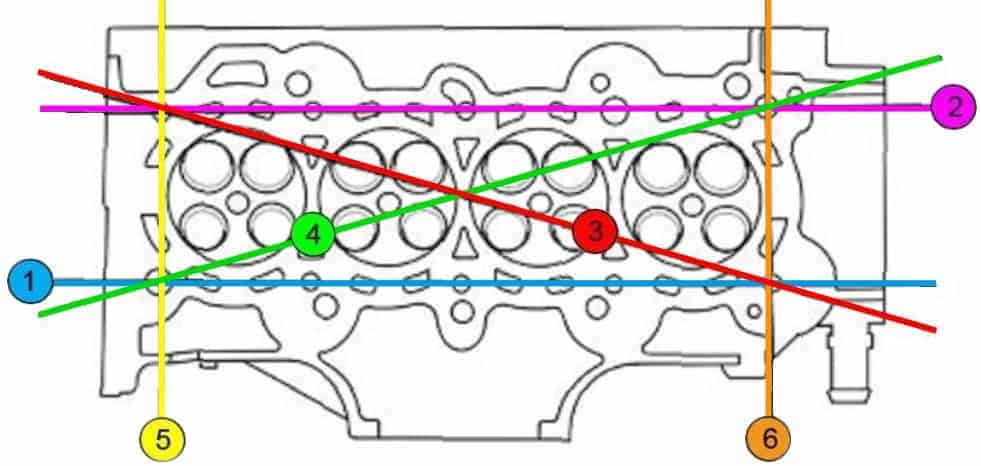

To determine the flatness, we need to make a total of six measurements on the engine block and on the cylinder head. The two images below show the positions in which the steel straight should be held. When we have the steel straight in position, we need to fit the feeler gauge at about half the length between the motor/head and the steel straight.

The maximum allowable clearance between the motor/head and the steel straight edge must not exceed 0,05 mm (if the manufacturer prescribes a different size). When a 0,1 mm feeler gauge can be slid between the motor or head and the steel straightedge, we can assume that we are dealing with deformation (a bent object).

If the deviation is very small, but just outside the tolerances, the cylinder head can be flattened by an overhaul company. During this process, the machine removes material from the head until it is straight. With large deviations and therefore coarse processing, this results in a smaller compression space. A thicker head gasket compensates for this difference.

Related pages: