Subjects:

- General

- How the Hall sensor works

- Hall unit with magnetic disc

General:

Hall or magneto-resistive sensors are often used in automotive technology. The task of these sensors is to measure the speed and pass it on to the appropriate control unit. This page describes the function and applications of the Hall sensor.

Operation of the Hall sensor:

A Hall sensor works by means of magnetism. There are 2 types of Hall sensors, each with their own function:

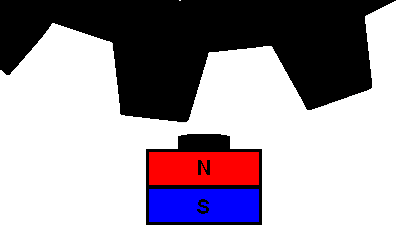

Hall sensor with permanent magnet:

By changing the air gap, an alternating magnetic field is created in the Hall sensor, which then generates the alternating Hall voltage. This type of Hall sensor is often used as a speed sensor, for example at the crankshaft gear. The speed of the crankshaft is passed on to the ECU which controls the ignition and to the instrument panel to control the tachometer.

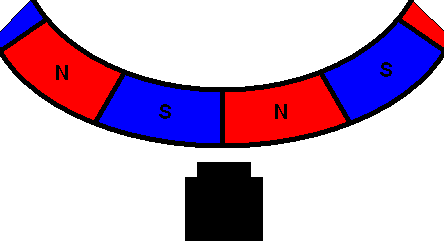

Hall unit with magnetic disc:

With this type of Hall sensor, a disc with magnets rotates along the mounted Hall unit. The rotation of the magnetic disk creates an alternating Hall voltage. This type of Hall sensor is often used as an ABS speed sensor. Compared to the system with a sprocket, this system has the great advantage that it works at a lower speed. Due to the rotating magnetic disc, a good speed can already be registered with a slowly rotating wheel (at less than 5 km/h), which was not possible with the system with sprocket.

The magnetic disc is incorporated in the wheel bearing. These cannot be replaced separately.

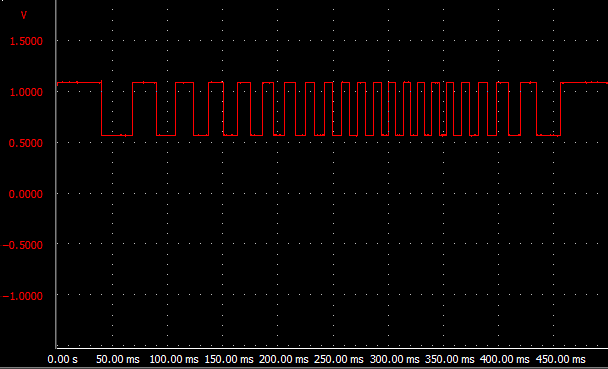

The voltage curve of the Hall sensor can be displayed with an oscilloscope. Below is a scope image of an ABS sensor, which is designed as a Hall sensor. The frequency changes as the speed of the wheel changes (the square voltage gets wider or narrower). The amplitude (the height of the signal) remains the same.