Subjects:

- General

- Three Way / Oxidation Catalyst Operation

- Working temperatures

- NOx Catalyst Operation

- Aging and its causes

General:

The name Catalyst originally comes from the Greek word Katalysis (meaning decomposition). A catalytic converter has been necessary since the end of 1992 to comply with environmental requirements. Exhaust gases contain the harmful substances: CO (carbon monoxide), NOx (nitrogen oxide) and CH (unburned hydrocarbon). These substances are (oxidized) to non-harmful substances. Hence the name Oxidation Catalyst sometimes.

In chemistry, a catalyst is understood to mean a substance that triggers and speeds up or slows down a chemical reaction without undergoing any change itself.

Three Way / Oxidation Catalyst Operation:

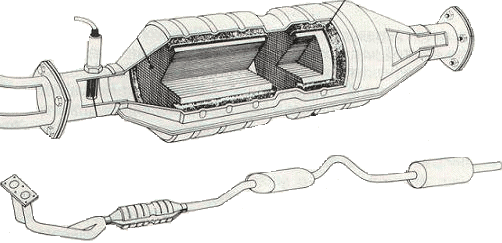

A catalyst is not a filter, but can be seen as a conversion element in which precious metals such as platinum, rhodium or paladium have been applied. If the exhaust gases come into contact with it, a very fast chemical reaction occurs. The molecules of the harmful gases are decomposed and bonded with other molecules resulting in a non-harmful gas. The catalytic converter is able to purify the exhaust gases for 90%. However, this comes at the cost of higher consumption and lower power. This is because it creates a certain air resistance in the exhaust path.

Substances in the exhaust gases:

- CO2: Carbon dioxide (at high concentrations harmful to the environment, humans and animals)

- CO: Carbon monoxide (incompletely burned gas, also harmful to health)

- CH: Hydrocarbons (unburned gasoline parts)

- O2: Oxygen parts (which did not participate in combustion)

- NOx: Nitrogen compound (which is only formed under very high combustion temperatures.

The catalyst converts the 3 harmful components CO, HC and NOx into 3 harmless components: CO2, H2O and N2. The name three-way catalytic converter also comes from here.

In order to add O2 and CO to the catalytic converter so that the conversion can take place, the injection pattern of the engine must be adjusted. To form O2, the mixture must be lean (less fuel, more air). To form CO, the mixture must be rich (more fuel, less air). The latter is not the case with lean-mix engines, see the NOx catalyst section further down the page.

By always injecting a little too much and a little too little fuel into the cylinders, a rich and lean mixture is always created. The surpluses of CO and O2 end up in the catalytic converter. In the catalyst, the platinum reacts with the CO and HC. The rhodium ensures the reduction of the NOx. This also explains why a varying voltage is measured when the oxygen sensor is measured. There the voltage varies between 0,2 and 0,8 Volt (from poor to rich, etc.). The engine management system of the car (the ECU) regulates this itself. So nothing needs to be adjusted.

| Harmful substance: | Add from: | Results in: |

| CO+ | O2 = | CO2 |

| HC+ | O2 = | CO2 + H2O |

| NOx+ | CO = | N2 + CO2 |

In order to add O2 and CO to the catalytic converter so that the conversion can take place, the injection pattern of the engine must be adjusted. To form O2, the mixture must be lean (less fuel, more air). To form CO, the mixture must be rich (more fuel, less air). The latter is not the case with lean-mix engines, see the NOx catalyst section further down the page.

By always injecting a little too much and a little too little fuel into the cylinders, a rich and lean mixture is always created. The surpluses of CO and O2 end up in the catalytic converter. In the catalyst, the platinum reacts with the CO and HC. The rhodium ensures the reduction of the NOx. This also explains why a varying voltage is measured when the oxygen sensor is being measured. There the voltage varies between 0,2 and 0,8 Volt (from poor to rich, etc.). The engine management system of the car (the ECU) regulates this itself. So nothing needs to be adjusted.

What can be seen in the table above is that the substances are all converted to CO2 among other things. Today CO2 is seen as a substance that is hazardous to the environment and responsible for global warming. However, a person also exhales CO2. This is converted back into O2 (oxygen) by trees and plants. Too much CO2 has a harmful effect. The trees and plants are outnumbered and unable to convert everything to O2. For combustion engines, the CO2 content should be as high as possible. That sounds crazy, because you would think that it would be kept as low as possible. That's how it is; the higher the CO2 content, the less CO and HC is released. CO and HC are directly harmful to health when inhaled. The only way to reduce the CO2 content is by switching to alternative fuels, smaller (more economical) combustion engines and a calmer driving behaviour.

Working temperatures:

The useful effect of the catalyst starts from a temperature of 250 degrees and is maximum at a temperature of 450 degrees. After starting the engine, it takes a while before the purifying effect starts. The catalytic converter is mounted as close to the exhaust manifold as possible, as this allows it to reach its working temperature sooner. Exhaust gas temperatures between 800 and 1000 degrees cause faster thermal aging, which shortens the service life and therefore reduces the active surface area.

There are also catalytic converters with a heating element that ensures that the catalytic converter heats up even faster after a cold start. This can then regulate even faster after the engine is switched on, resulting in cleaner exhaust gases

To warm up the catalytic converter as quickly as possible after a cold start, a secondary air pump.

Operation NOx catalyst:

It was previously explained that NOx can be reduced by the catalytic converter by getting extra CO in the exhaust gas. This is only possible to make the mixture richer. In the lean-mix engines of, among others, Volkswagen (FSI) and BMW (Efficient Dynamics), the engines in partial load and low speeds always run on a mixture with an excess of air (ie lean, and never rich). With a normal three-way catalytic converter it is therefore impossible to convert NOx into N2 + CO2. In order to still remove the NOx from the exhaust gases, a special NOx (storage) catalytic converter with a special barium component is required. In addition to the barium component, this catalyst also contains precious metals such as platinum and rhodium.

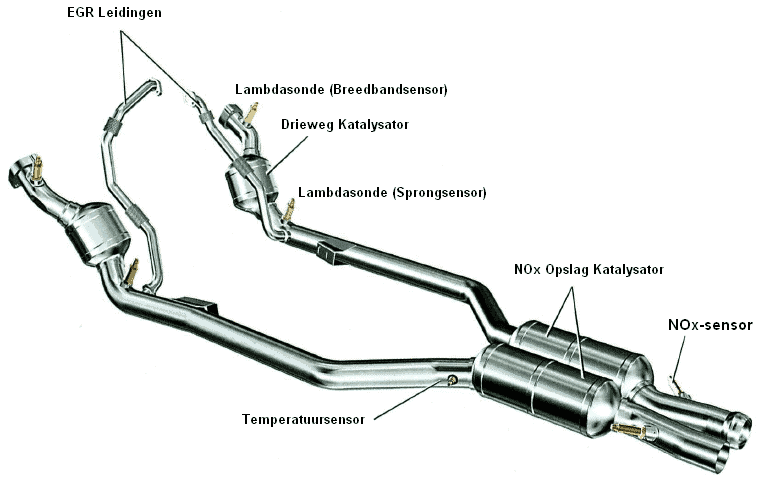

The three-way catalyst converts the CO and HC values into CO2 and H2O as described earlier. The NOx is converted by the NOx catalyst. Additional temperature sensors and a NOx sensor are required to constantly monitor the values.

The image below shows an exhaust system as used by VW, BMW (and more and more other brands) among others.

The NOx gases are stored in this catalyst in a cold state. The other exhaust gases can continue their way through the exhaust. During the oxygen-rich period, the NOx gases are stored in the barium component. The NOx accumulates (just like soot is stored in a particulate filter). Over time, the catalyst becomes saturated. That is when it is full of NOx. The catalyst must then be regenerated. The NOx sensor recognizes this and sends a signal to the ECU. At this point, the mixture is made rich, especially to regenerate the NOx catalyst. This only happens when the NOx catalyst has reached a temperature of 800 degrees (this is registered by the temperature sensor and also passed on to the engine control unit). With the temporary enrichment extra CO is released. With the help of this CO a conversion to N2 + CO2 can take place through the platinum and rhodium components. After regeneration, the engine will run on a lean mixture again until the catalytic converter is saturated again.

Malfunctions may also occur with this system. When the car is only driven for short distances (which is bad for the entire car), the NOx catalytic converter will also not be able to reach its working temperature. As soon as it is saturated (full) it will have to be regenerated. Only if the temperature sensor continues to measure a temperature that is too low, the ECU will never enrich the mixture. If the catalyst is not at operating temperature, the platinum and rhodium components cannot yet provide a conversion. At this point, the engine trouble light will come on and the car reading will reveal the cause. The catalytic converter will then be regenerated with the aid of the test cabinet or a solid test drive. It is therefore best to occasionally drive a long piece (of, for example, 50 km or more on the highway) and preferably a piece with an increased speed. The catalyst will then be able to easily reach its working temperature.

Today, in diesel engines, the SCR (Selective Catalytic Reduction) catalyst applied. NOx is also stored in this SCR catalytic converter, but there is also a AdBlue dosing system added to.

Aging and its causes:

- Gasoline: A three-way catalytic converter can only work with unleaded gasoline. If lead-containing petrol is nevertheless refueled, it adheres to the precious metal in a thin layer, so that contact with the exhaust gases decreases and after a while it is no longer possible. No chemical reaction can then occur. The catalytic converter is now inoperative and must be replaced. That is a costly matter. Leaded petrol was added to achieve a certain knock limit (knock limit). Because knock sensors are used nowadays, the lead has been removed from the fuel.

- Oil also has a devastating effect on the interior. If there is a lot of oil leakage along, for example, the piston rings, valve guides or the turbo, a lot of oil can end up in the catalytic converter. The oil also causes a layer to adhere to the precious metal, which then loses its effect.

- Short trips: By driving many short trips, the catalytic converter rarely if ever reaches its operating temperature. The unburnt HC (petrol) residues adhere to the ceramic surface. If it is driven for a long distance, these HC residues are still incinerated. If short distances are driven, these HC residues also adhere to the interior, causing the catalytic converter to lose its function over time.

The second lambda probe (the jump sensor) often measures whether the catalytic converter has converted the gases properly. Should the catalytic converter age or if the interior is defective, this second lambda probe will measure this. A fault light will then illuminate on the dashboard. It is then necessary to replace the catalytic converter. More information about the lambda probe can be found on the page Oxygen sensor.