Subjects:

- Preface

- Operation of an LED

- Conductive voltage in relation to the color of the LED

- Control Methods

- Multi-color LEDs

Preface:

An LED is a commonly used semiconductor component to emit light. LED stands for: Light Emitting Diode and means: Light Emitting Diode. After its invention in 1962, the LED has been mainly used as an indicator light and for signal transmission. Technological developments have made it possible since the late 90s to produce LEDs that serve as a light source for everyday use. In automotive technology, LEDs are frequently used as instrument lighting (dashboard), exterior lighting (rear lights) or main lighting (in the headlamps) due to the following advantages over incandescent and halogen lamps:

- low energy consumption: with the same light intensity compared to other types of lamps, the LED uses considerably less energy. The LED has a very high efficiency of up to 80%;

- safety: incandescent bulbs need about 200ms to warm up the filament and emit light. An LED does not need a warm-up phase, which means that an LED reaches its light intensity faster (in less than 1 millisecond). When an LED is used as a brake light, braking is noticed earlier and has a positive influence on the stopping time;

- low heat development: because LEDs hardly heat up, lamp housings can be made smaller and cheaper materials can be used that are less resistant to thermal stress;

- long lifespan: an LED lasts approximately a whole car life. If it turns out that LEDs are defective, the cause can often be found elsewhere, such as a break in the print path or incorrect control. The brightness of an LED can decrease with a certain number of burning hours.

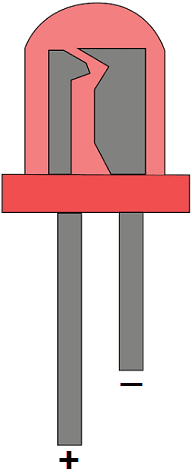

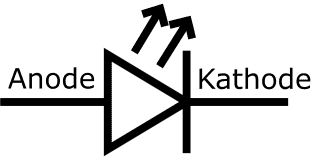

The picture opposite shows the symbol of the diode, with additional text above the “anode” and “cathode” sides. The symbol of an LED is almost identical to that of a diode, but two upward arrows have been added, which indicate the light radiation. As with the diode, the current direction is in the arrow direction. The vertical stroke is the blocking direction. If the current flows through the LED in the direction of the arrow, it will light up. Conversely, it will block and therefore not light up.

Operation of an LED:

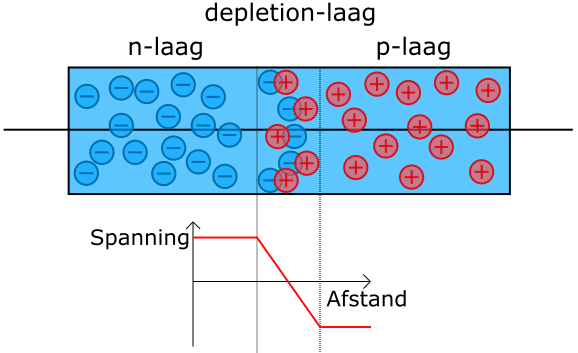

As with a “normal” diode, the LED consists of two semiconducting layers:

- the negative layer (n-layer) contains an electron surplus;

- the positive layer (p-layer) has a shortage of electrons.

The shortage of electrons in the p-layer can be seen as some excess of positive holes. In the pn junction (depletion layer), the surplus of electrons in the n layer will fill the holes in the p layer. No current flows yet, so the charge in the np junction is neutral.

In order for the current to flow through the diode, the internal voltage of the depletion zone must first be overcome. This is the so-called diffusion voltage or threshold voltage of the diode. When the voltage is increased, the electron current will be able to flow from the n-layer to the p-layer. In the depletion layer, however, some of these electrons are captured by the holes. These electrons give off part of their energy in the form of flashes of light. The generated light can escape through the thin p-layer. The light intensity is determined by the current intensity: the stronger the current, the more intense the light.

The jumping of the valence electrons from the negative to the positive layer creates the light that the diode emits.

Conductive voltage in relation to the color of the LED:

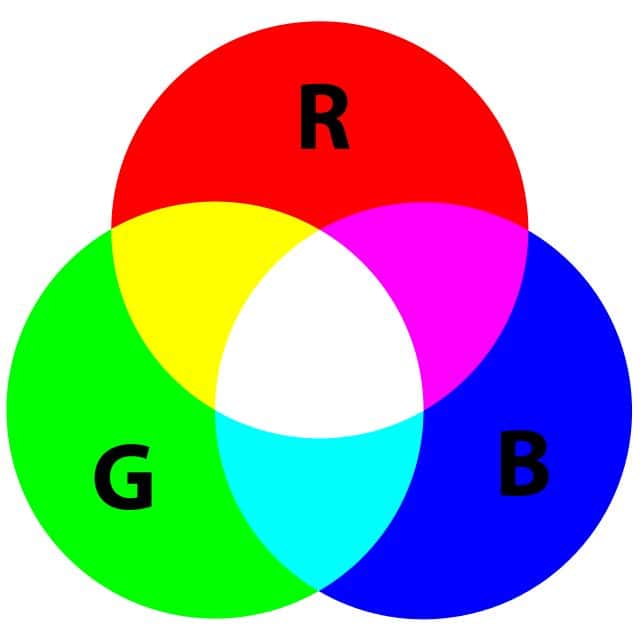

An LED is available in three colours: red, green and blue. With these three basic colors, other colors can be obtained by mixing them. The composition of materials of the n and p layers determine the amount of energy in the electrons and holes.

- Low-energy electrons convert less energy into light radiation than a high-energy electron;

- Red light has less energy than blue light;

- Red is created by low-energy and blue by high-energy electrons.

White LEDs cannot be produced. By adding an extra fluorescent layer to a blue LED, some of the blue light is converted into yellow light. The mixture of blue and yellow light is perceived by the human eye as white light. By adjusting the mixing ratio between this yellow and blue light, warm or cold white light can be emitted.

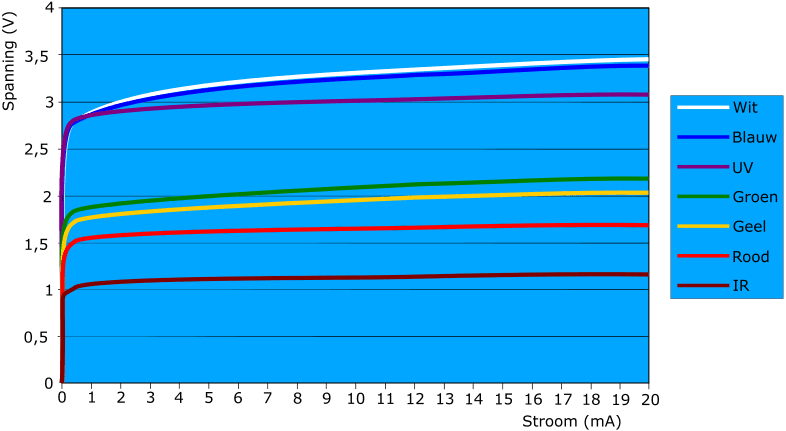

In the characteristic curve we see the voltage that is built up in the depletion zone and is therefore the conduction voltage of the respective color LED. When current is sent through an LED, a nearly constant voltage drop is created.

Control Methods:

In automotive technology, we can use LEDs with a series resistor or in series circuits, so that we reach the desired control voltage.

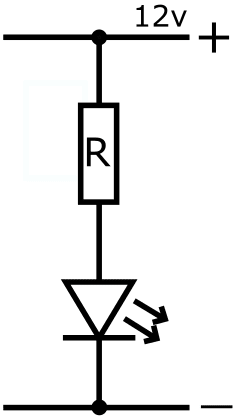

LED with series resistor:

If we connected an LED directly to the plus and minus of the battery, the LED would immediately fail. There always has to be one series resistor placed in series with the LED.

The value of the series resistor is determined by two factors: the current and the supply voltage. A red LED lights up as soon as the operating voltage of 1,5 volts has been reached and approx. 20 mA flows through it.

The supplied supply voltage depends on the application. In the automotive industry this can be 5, but also 12 or 24 volts. The required resistance can be determined using Ohm's Law. Subtract the operating voltage from the supply voltage and divide by the current.

- at a supply voltage of 5 volts, a series resistor of (5 – 1,5) / 0,02 = 175 ohms will be required for the red LED.

- at a supply voltage of 12 volts and a red LED: (12 – 1,5) / 0,02 = 525 ohms (one factor higher resistance).

The LEDs with series resistors are mainly encountered in retrofitted LED lighting (retrofit). The fast on and off times and the brightness of an LED can be a reason to replace incandescent bulbs with LEDs. You don't have to worry about energy efficiency, since the series resistor also causes a power loss that in some cases is just as great as the power dissipation of the original lamp.

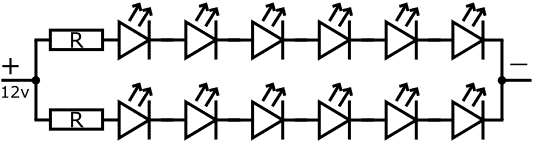

To daisy-chain LEDs:

By connecting the LEDs in series, no or a low-resistance series resistor is required. The internal resistance of the LEDs themselves ensures that the supply voltage is distributed over the LEDs in the series connection. The more LEDs are placed in series, the smaller the series resistor can be made. In the figure, six LEDs are connected in series and two rows are connected in parallel.

The LEDs connected in series can be found in rear light units or third brake light units. This is a widely used control method in automotive technology.

Adjust light intensity:

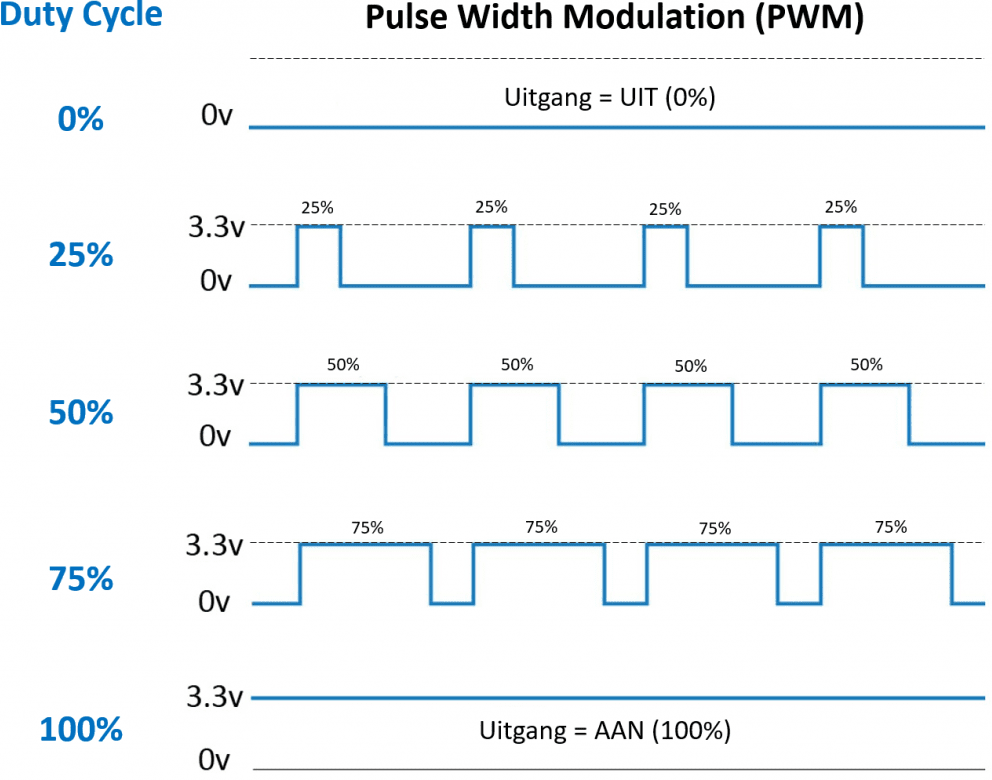

With a microcontroller we can control the control of an LED with a pulse. We call this: Pulse Width Modulation (PWM).

The duty cycle determines the time at which the LED is activated. By alternating the on-off pulses between 3,3 and 0 volts at a high speed, the LED will light up at a lower brightness.

This control method is the same on a light bulb with multiple functions, think of:

- 50% bright with lights turned on;

- 100% bright with brake light on.

In a lab setup with an Arduino, one can experiment with the PWM control of the LEDs on the Arduino or externally connected LEDs (equipped with series resistors).

Multi-color LEDs:

All colors can be combined with the three basic colors red, green and blue. This can be usefully used by combining two or three LEDs. Below are three principles that are used to obtain multiple colors by means of an electrical circuit.

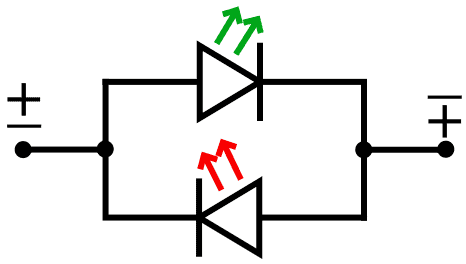

Two-color LED:

The schematic shows two LEDs connected in parallel, with the reverse and forward directions reversed. The current direction determines which LED is lit: green (top) or red (bottom), The polarity is reversed by an external circuit or ECU.

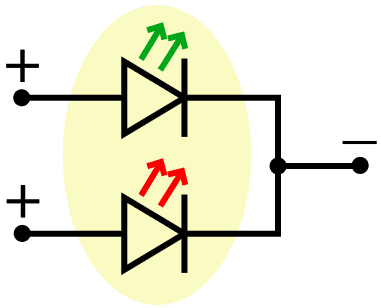

Tri-color LED:

Also in this diagram are two LEDs connected in parallel. In the circuit, a supply voltage can be applied to one of the two LEDs (green or red), or both at the same time. In that case, color mixing occurs and the red and green LEDs turn yellow.

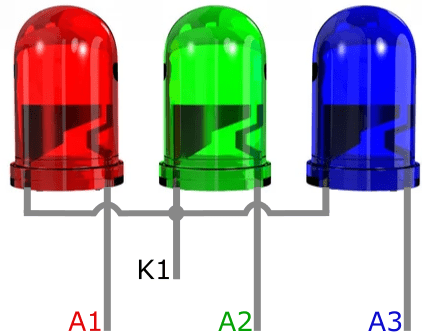

RGB LED:

With RGB LEDs, three LEDs, each with their own color, are housed in one housing. The colors can be controlled separately from each other. To control the RGB LED, three PWM drivers are required, which generate an adjustable on/off ratio on each power pin. In addition to the different colors, the light intensity can also be adjusted with this.

In the following figure we see three LEDs, each with their own Anode connection (A1 to A3) and a common Cathode.