Subjects:

- Preface

- Operation

- Maintenance

Preface:

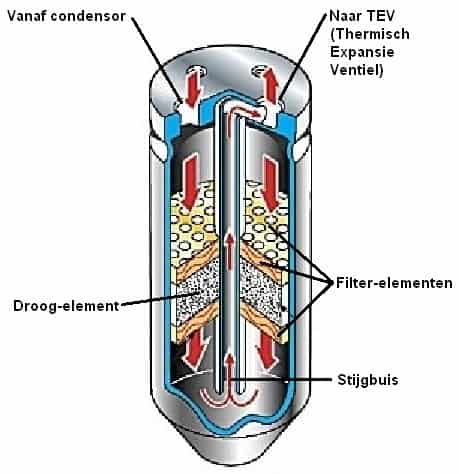

The dryer/filter element (2 functions in 1 component) is mounted in air conditioning systems with a TEV valve (Thermal Expansion Valve). The dryer/filter element (hereinafter simply referred to as “the dryer”) is placed between the condenser and the TEV valve. The dryer is often attached to the condenser and sometimes they even form one whole.

The refrigerant is led from the condenser in a liquid state through the dryer. The compressor ensures the pressure and circulation of the refrigerant in the system. The condenser has previously converted the refrigerant from gaseous to liquid state, so it can now be filtered better.

Operation:

The dryer's task, among other things, is to remove dirt and moisture from the refrigerant. It is crucial to keep the air system free of moisture. When moisture is present in the system, for example due to a saturated drying element, there is a risk that it will freeze at a certain point in the system, such as the evaporator, because this is the coldest point. This can lead to blockages and reduced cooling capacity of the air conditioning. As a result, the interior of the car will warm up. After the air conditioning has been turned off for about fifteen minutes, the evaporator has had time to defrost and the air conditioning will function normally again for a few minutes.

The drying element is filled with silica gel or silicate granules in which moisture-absorbing crystals of silicate are present. These granules absorb moisture from the refrigerant as efficiently as possible. The other internal filter elements ensure that wear and dirt particles are retained. The clean and dry refrigerant then leaves the dryer via the riser (see figure) and is then led to the TEV (Thermal Expansion Valve), which is attached to the evaporator, where the refrigerant continues to flow.

Another function of the dryer is to store refrigerant. This storage allows any gas bubbles to escape, providing the expansion valve with a constant flow of refrigerant (in liquid form). This smoothes out pressure waves. This can be compared to the operation of an accumulator.

Maintenance:

The dryer/filter element can become saturated when the drying element (the silica gel or silicate granules) has absorbed so much moisture that it is no longer absorbent. The moisture is absorbed once and is never released again. When the dryer/filter element can no longer function effectively due to the large amount of moisture, we speak of “saturation”.

Over time (often years) there is a risk of saturation, especially if the air conditioning system has been emptied and refilled several times at an air conditioning station. Each time the station is connected, or when any work on the system involves disconnecting pipes, a small or large amount of outside air may enter the system. The dryer/filter element immediately absorbs all moisture present in the outside air in the air conditioning system. It is therefore advisable to replace the filter/dryer element after work on the air conditioning system.

Another cause of saturation can be incorrect installation of the filter/dryer element. When a new element is installed, cover caps are present. These caps should only be removed when the relevant pipes of the system are installed. If these cover caps are removed too early and the pipes are not mounted on the dryer until a few minutes later, the drying element will be exposed to the outside air for too long. This allows a certain amount of moisture to penetrate. It is therefore wise to replace the complete filter/dryer element each time the system is emptied and refilled.

This can be compared to replacing an oil filter in a car when changing the engine oil.

Related page: