Subjects:

- Evaporator

- Expanding the refrigerant

- Freezing the evaporator

- Possible malfunctions and defects

Evaporator:

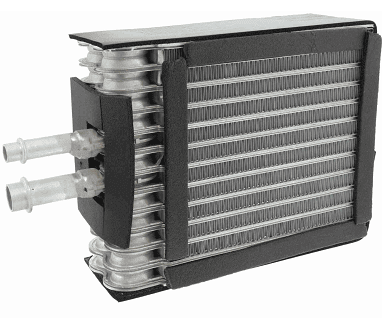

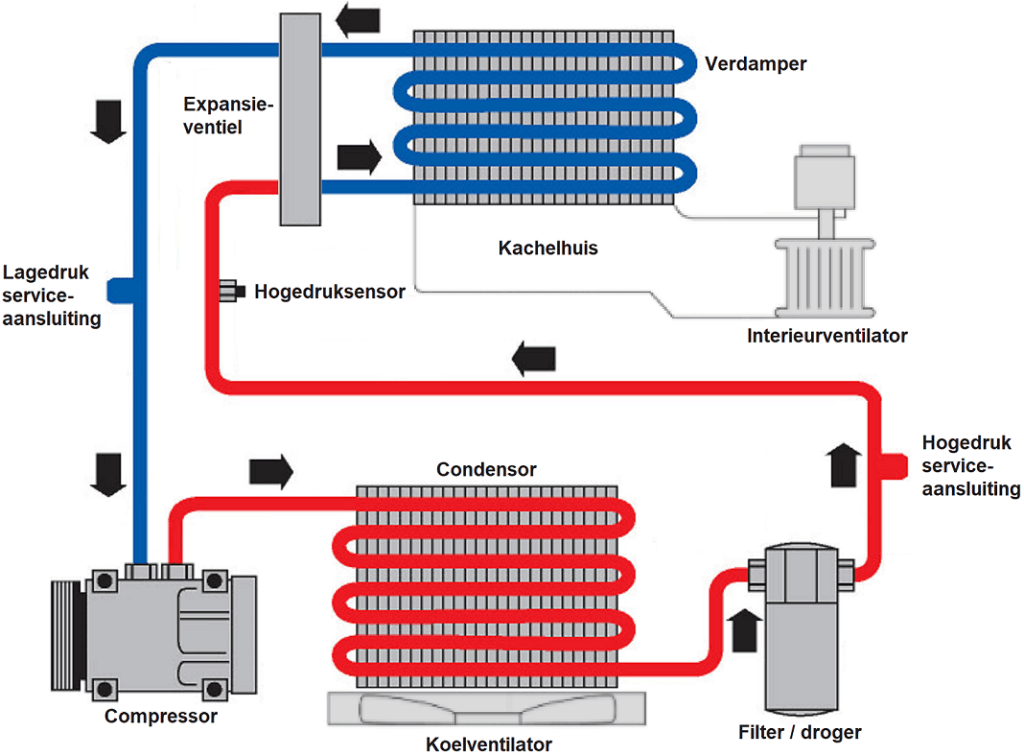

The air that is blown into the passenger compartment by the passenger compartment fan undergoes a cooling process by the air conditioning that is switched on. This cooling process of the air takes place in the evaporator. The evaporator is built in under the dashboard, in the heater housing. This is composed of bent pipes with aluminum heating plates or rows of aluminum tubes.

Gaseous, vaporized refrigerant flows through the evaporator. The evaporator extracts heat and moisture from the air that the interior fan blows through or is drawn in by evaporation of the refrigerant. You notice the same effect when you get disinfectant on your skin; that feels cold because of the rapid evaporation of the disinfectant liquid on your skin. A small portion of body heat is transferred to the surrounding air.

The air from the interior fan transfers its heat to the evaporator. The cooled and dehumidified air is then guided through the stove dampers to the appropriate outlets, through which it reaches the interior.

When the air conditioning is switched off, there is refrigerant in the evaporator, but it is not pumped around by the air conditioning compressor. The interior fan blows or sucks the outside air through it at that moment. At that moment, the evaporator takes on the temperature of the outside air.

Expanding the refrigerant:

During the circulation of the refrigerant in the air conditioning installation, the refrigerant goes through different states: liquid, vapor or a combination of both. These are called the so-called aggregate states. As the name suggests, the refrigerant will evaporate in the evaporator. Evaporation takes place after expansion. We will discuss this in more detail in the next section.

After the refrigerant has passed the filter/drier element, it reaches the expansion valve with a (high) pressure of approximately 15 bar and a temperature of approximately 55 degrees. This valve is mounted directly on the inlet and outlet of the evaporator. In the expansion valve, the transition from high to low pressure takes place. There is a constriction inside the expansion valve through which the refrigerant is forced. This constriction ensures a pressure reduction of the refrigerant from about 15 bar to 2 bar. This sudden drop in pressure results in a reduction in the boiling point of the refrigerant. As a result, the refrigerant changes from liquid to saturated vapour. This means that both vapor and liquid particles are present.

Heat is required for the evaporation of liquid. To enable the transition from liquid to gas, the refrigerant extracts heat from the air flowing through the evaporator. This air cools down and then flows into the interior. This heat causes the liquid particles to turn into vapour.

There are two types of expansion valves: the Thermal Expansion Valve (TEV) and the Capillary. Both types are described on the expansion valve page.

Freezing the evaporator:

In some cars, the evaporator may freeze. At that moment, no more air can flow through the evaporator, so that no more air is blown through the ventilation grilles. This phenomenon often occurs after using the air conditioner for a long time. Due to the extremely low temperature of the evaporator and the presence of excessive moisture, the moisture in the evaporator can freeze and cause blockages. A potential cause for this could be a clogged water drain.

In air conditioning systems, moisture is extracted from the outside air, which forms as condensation on the evaporator and is discharged into the street via the water drain. That is why you often see a puddle of water under the car when the outside temperature is high and the air conditioning is on.

When the water drain is functioning correctly, ways to increase the temperature of the evaporator can be considered. On certain cars this can be controlled electronically using diagnostic equipment in a garage. For systems with a capillary tube, replacing the expansion member can offer a solution. A capillary with a larger constriction can be fitted, resulting in less pressure reduction than with a capillary with a smaller constriction. Less depressurization also results in a less significant drop in the refrigerant temperature. This may be enough to prevent freezing of the evaporator.

Possible malfunctions and defects:

When an air conditioner is not functioning properly, the technician often first checks the pressures in the system. Depending on the malfunction, the evaporator may be to blame. Here are the most common evaporator malfunctions and defects:

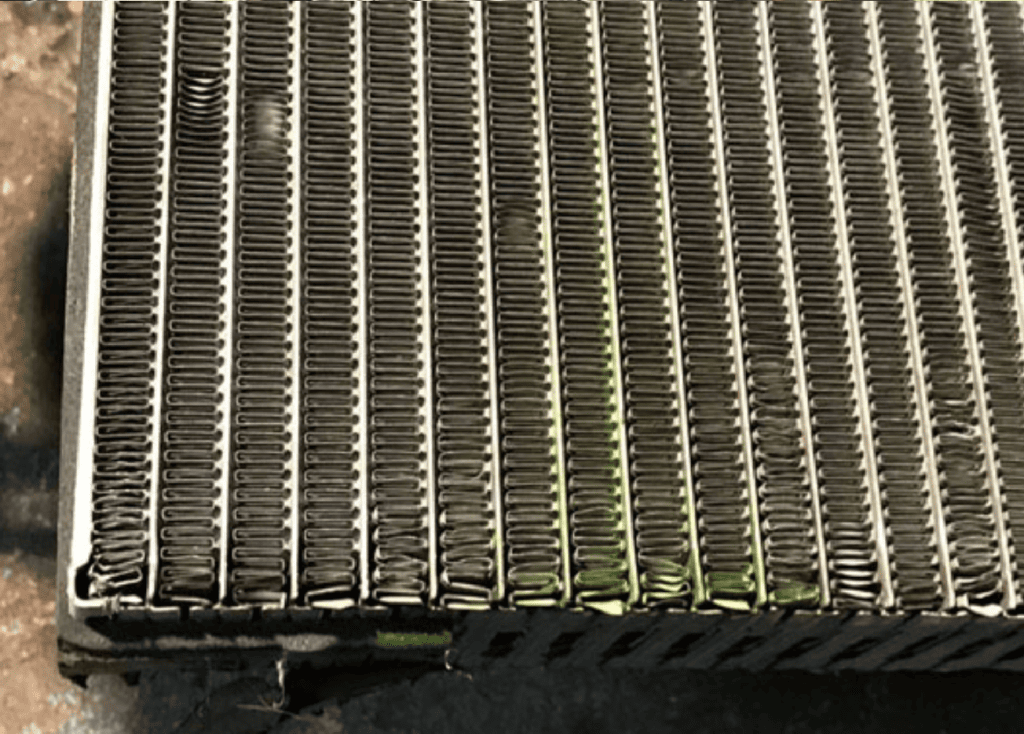

- Leakage: One of the most common problems is leakage. This can be caused by corrosion, expansion and shrinkage and thus aging of the material. The evaporator is built into the heater housing behind the dashboard. To dismantle the evaporator, it is therefore often necessary to dismantle the entire dashboard and heater housing. This is a labour-intensive job. In the image below we see a disassembled dashboard and heater housing, with next to it the leaking evaporator of a BMW 1-series (2012). Leaking refrigerant can reduce the performance of the air conditioning system, resulting in a completely empty system. When all refrigerant has escaped and the pressures are too low, the compressor no longer switches on for safety reasons.

When checking for leaks, we use a leak detector. When the installation is filled with a UV additive, yellow/green spots are visible around the leak. However, the evaporator is often so difficult to reach that a visual check is not possible. The leak detector should offer a solution. - Constriction or blockage: Impurities or deformations of the material can restrict the airflow through the evaporator. By measuring the pressures and temperatures, we can recognize whether this is the case.

Related page: