Subjects:

- Operation of the drum brake

- Different versions of the drum brake

- Adjusting the brake shoes

- Measuring brake drum wear

Operation of the drum brake:

Drum brakes mainly consist of a brake drum and anchor plate with the brake shoes and wheel brake cylinders mounted thereon. By pressing the brake pedal, the pistons of the wheel brake cylinders are pushed out. These pistons push the brake shoes against the brake drum. After releasing the brake pedal, the return springs ensure that the brake shoes return to their rest position.

This page will be updated soon!

Different versions of the drum brake:

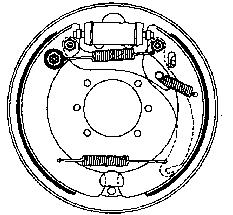

Simplex

With the Simplex construction, both brake shoes are pushed out by one two-piston wheel brake cylinder. There is a pivot point between the lower parts of the brake shoes.

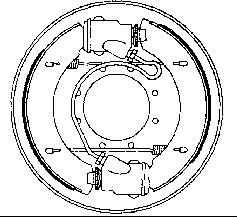

Duplex

The duoplex system uses two wheel brake cylinders, each with one brake piston. Each brake shoe is pressed by its own brake cylinder. When driving forward, both brake shoes have a self-energizing effect, which means that the braking force is greater than with simplex brakes. When reversing, there is no self-propulsion with either brake shoe. So there is a big difference in braking power when driving forwards and backwards.

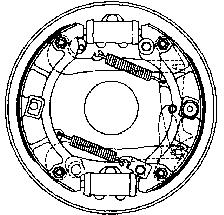

duo duplex

The duo-duplex system also uses two brake cylinders, but then double-acting as with the simplex brakes. In this way, the same braking force is generated when braking both forwards and backwards.

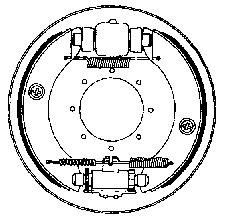

Servo

Servo brakes are equipped with one double wheel brake cylinder (at the top) with the adjustment mechanism at the bottom. The servo system allows particularly powerful braking. The primary shoe presses on the secondary shoe through the self-energizing effect and via the push pin that slides to the right. This also gives it self-empowerment. When braking in reverse, only the right brake shoe has self-energizing effect.

duo servo

The duo servo brake is equipped with one double wheel brake cylinder. The difference with the servo brake is that the push pin can now move both to the right and to the left. As a result, the two brake shoes have a self-energizing effect when braking forwards as well as when reversing.

Adjusting the brake shoes:

The brake shoes should be as close as possible to the brake drum. If not, the brake pedal will have to be depressed more deeply before the shoes touch the brake drum.

- Adjust manually:

To eliminate the effects of wear, it is necessary to adjust the brake shoes according to the prescribed maintenance schedule. How and where this should be done depends on the brake construction; eg with gears or a pin with a conical end. Instead of gears, eccentrics can also be used to adjust the brake shoes. Adjusting the brake shoes is usually done at the back of the brake backing plate. - Automatic adjustment:

There are also drum brakes with an automatic adjustment device. A special toothed rod is clamped by a spring-loaded driver. The head of the rod is anchored on the brake anchor plate. If the shoes move outwards when braking, the carrier pulls the rod with it.

Measuring the wear of the brake drum:

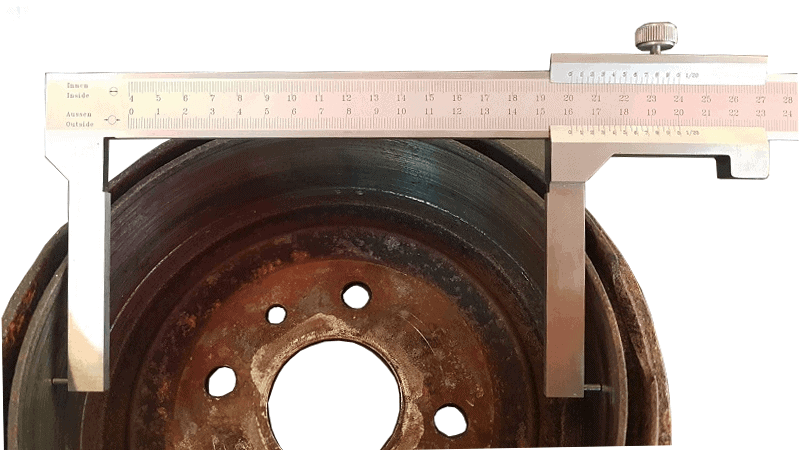

The inner diameter of the brake drum increases as it wears. In addition to the brake shoe linings, the diameter of the brake drum should also be checked for wear. The factory data of the respective car contains the values determined by the manufacturer. If the measured value is less than or greater than the factory data, the brake drums must be replaced.

The image below shows a special caliper for the brake drums. Distance pins can be seen on the outside of the measuring jaws. These spacer pins should be placed against the deepest point of the brake drum. Search therefore slide back and forth a number of times to find the deepest point. The largest distance indicated by the caliper is decisive.

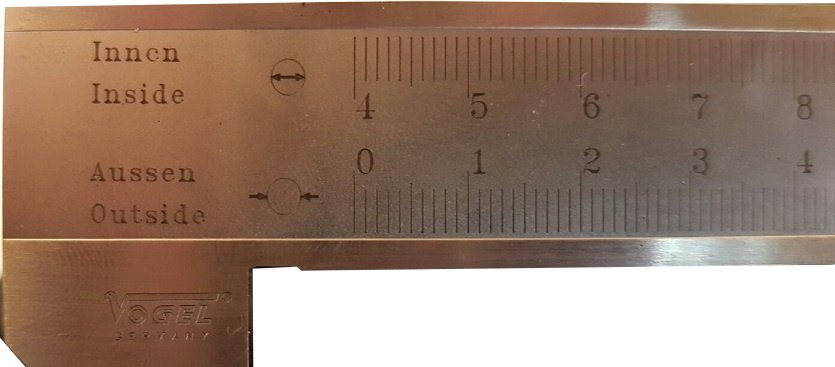

The next two images are an enlargement of the vernier caliper shown above. Two scales can be seen on the caliper. The inner diameter is shown on the top scale (Innen / Inside). We read this off, because we measure the inner diameter of the brake drum. The lower shell is of the outer diameter (Aussen / Outside). This can also be seen in the accompanying drawing.

The top scale starts at 4 cm (40 mm) because the measuring jaws including the spacers are 4 cm thick in total. Because the inner diameter of the brake drum has been measured, we read the upper scale.

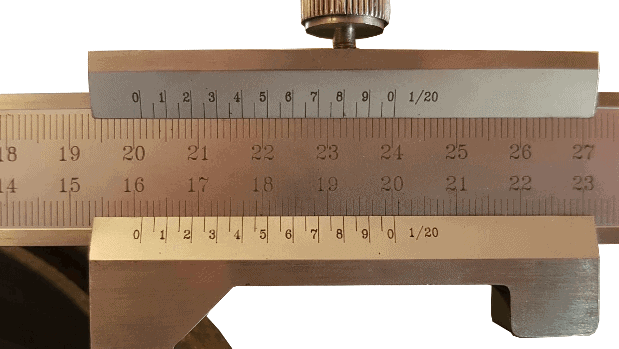

The value of the measurement can be read in the figure.

First of all, you need to check where the 0 of the vernier is near. This one is just past 20,1 cm (201 mm). That means there is another number after the decimal point. Which number that is depends on which dash of the vernier corresponds to the dash on the ruler. In this case, the 2 of the vernier matches. This means that the number after the decimal point is a 2, so that the measured value is 20,12 cm (ie 201,2 mm).

The factory data of the car in which this measurement was performed has a minimum measurement of 201 mm. The measured value of the brake drum is higher than the wear limit, so the brake drum must be to replace.

Related page: