Subjects:

- Role

- Lubrication

Position:

The connecting rod is a connection between the piston and the crankshaft and converts the translational movement of the piston into a rotational movement of the crankshaft (translating means going up-and-down). As the piston is pushed down, the connecting rod causes that force to be transmitted to the crankshaft, causing the crankshaft to rotate. After the crankshaft has been rotated 180 degrees, the connecting rod is pushed back up with a smooth movement, so that the piston returns to TDC.

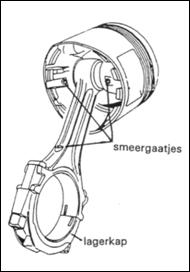

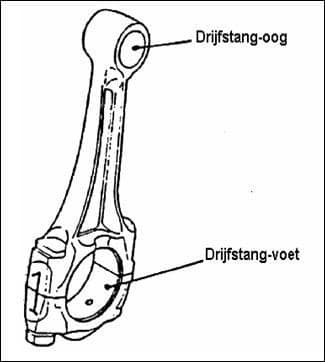

The connecting rod is connected to the crankshaft at the connecting rod foot (the bottom) by means of bearing shells and at the top it is mounted to the piston by means of a piston pin.

The large hole (the connection to the crankshaft) is also known as the "big-end". In order to withstand the high forces that are released during combustion with current engines, the connecting rod and the connecting rod base are not just separate parts that are mounted against each other. A connecting rod is manufactured as 1 piece of steel. After that, the connecting rod foot of the connecting rod itself is broken off. Because the broken parts contain a very rough surface, this gives extra strength after assembly. If both parts were smooth, friction could arise between them. Therefore, the parts must not be interchanged with each other.

Lubrication:

The connecting rod foot is lubricated by oil that comes from the pierced crankshaft. The connecting rod eye is lubricated by means of oil pressure in the lubrication holes and splash oil of the crankshaft or oil nozzles. The splash oil also cools the bottom of the piston (piston bottom).