Subjects:

- Control devices

Control devices:

There are many different control devices in modern cars. These control units each have their own function; the engine control unit receives information from all sensors in the engine compartment and controls the actuators. The image on the right shows an engine control unit. An engine control unit is also known as an Electronic Control Unit (ECU).

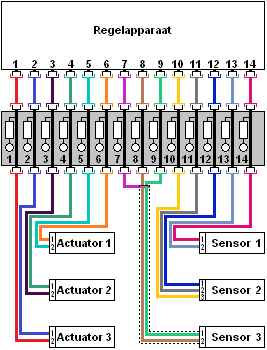

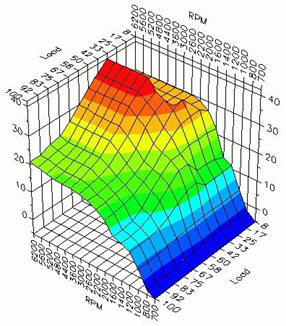

Two plugs are connected to this engine control unit, often with more than 100 separate wires. Each wire has its own function; For example, pin number 6 receives information from the coolant temperature sensor and pin 81 controls the fuel injector of cylinder 1. All sensors in the engine compartment send their own information to the ECU. In the ECU, this information is processed by the engine management system in a so-called map field. The image below shows an example of this:

In the map, the data from the sensors, such as the temperature of the outside air and the coolant, the position of the accelerator pedal, the turbo pressure, values of the lambda sensors, the engine speed, etc. On the basis of this data, the ECU determines at what time the injector should open and how long it is opened (the longer it is open, the more fuel is injected), but also the ignition time, the control of the turbo, etc.

Because the injection amount, ignition and turbo pressure all depend on the engine speed and load, it is important that the ECU processes this data properly.

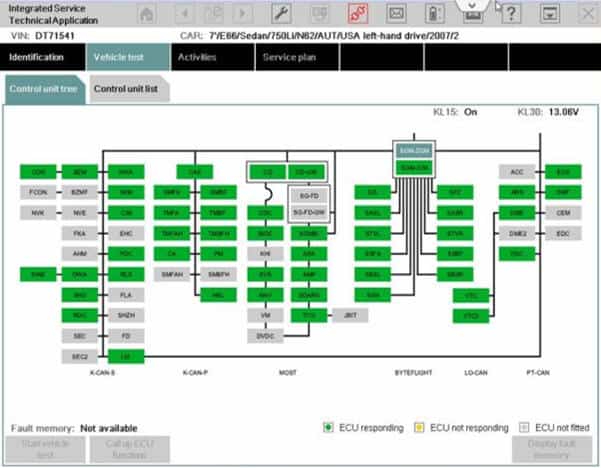

In modern cars there are often dozens of separate control units. The image shows a screenshot of a BMW readout computer.

This screen is from a BMW 7-series from 2007. Each green and gray block represents one control unit. So in total there are no fewer than 76 control units. The black lines indicate the cables to which the control units are connected. These cables include CAN bus cables. BMW gives its own names to the different networks (K-CAN-S, K-CAN-P, BYTE-FLIGHT, LO-CAN, PT-CAN). Each network has its own speed and is connected with a Gateway.

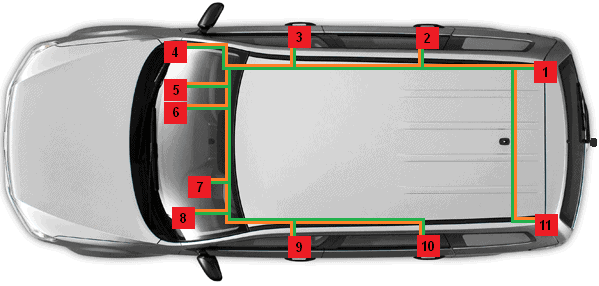

In the comfort network, all control devices related to the interior and body of the car are interconnected with CAN bus wires. This is called the CAN-B (comfort bus). The image below shows which control units all fall under the heading “comfort”.

1. Towbar installation control unit

2. Door control unit RA

3. RV . door control unit

4.Gateway

5. Comfort control unit

6. Alarm system control unit

7. Instrument panel

8. Steering column electronics control unit

9. LV . door control unit

10. LA . door control unit

11. Park Distance Control Control Unit

The various control units can be mounted anywhere in the car; in the dashboard, in the doors, in the tailgate, above the headliner, you name it. The technician can look up the location of the relevant control unit in the workshop documentation or sometimes even in the readout equipment. In this example, only a small amount of control devices can be seen. In reality, this could be dozens.

In addition to the comfort bus (CAN-B) of the example, there is also a drive bus (CAN-C). All communication takes place from the engine to the wheels via the drive bus. An important difference between these two buses is the speed: CAN-B operates at a speed of up to 125kbit per second and CAN-C at a maximum speed of 1Mbit per second. The speed at which the electric seat adjustment is controlled (CAN-B) does not have to be as high as the communication between safety systems of the Anti-Blocking System (ABS).

In addition to the different CAN bus systems with different speeds, there are also other network systems to allow control units to communicate with each other, such as LIN bus and MOST bus. A Gateway is used to link these networks together. Without this gateway, the control units of the CAN-A network, for example, cannot communicate with the CAN-B network. The gateway is in fact a node and a translation computer between the different networks. Click here for more information about the Gateway and the different types of networks.

When voltages or signals need to be measured on the plug of the control unit, a breakout box can be placed between the cable harness and the control unit (see figure below). The breakout box contains a large number of measuring points. Click here to go to the page about the breakout box to go.