Subjects:

- imbalance

- To balance

- Amount of imbalance

- Lead

Imbalance:

There are minor irregularities in every tire, whether it is new or old. The tire is always slightly heavier on one side than the other. The irregularities in the tire create an imbalance during driving, due to radial forces (from the center outwards). This imbalance can be noticed by the vibration of the steering wheel or the entire car.

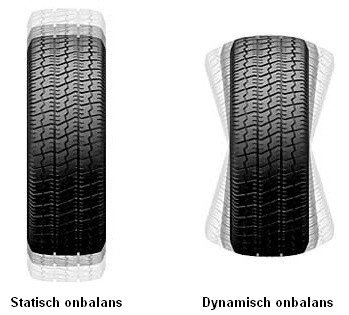

There are 2 different types of imbalance; static and dynamic imbalance. With static imbalance, the belt moves up and down, because the weight at the top of the belt is higher than at the bottom. The forces on the rolling belt are not uniform. With increasing speed, the force of the imbalance will also increase. This also increases the vibration. In the event of a static imbalance, the car will vibrate mainly as a whole.

With dynamic imbalance, the tire moves more from the inside out, which gives a swaying effect. This is especially noticeable in the steering wheel, when it moves very quickly from left to right. The vibration will also increase at higher speed.

To balance:

After mounting the tire on the rim, the complete wheel must be balanced. The wheel is placed on a balancing machine, which can determine exactly where the irregularities in the tire are and how big they are. This imbalance is eliminated by hitting or sticking a lead on the designated side of the rim. The screen shows on the left how much lead has to be glued to the inside of the rim, and on the right of course on the right side. By turning the wheel to the position where the device indicates it, the lead can be applied to the rim.

Closing the hood again causes the wheel to spin again and the imbalance is measured again. The screen should now show 0 on both the left and right. If there is another imbalance (eg 5 or 10 grams) it means that the balance is not correct and the previously applied lead should actually be removed and rebalanced. Otherwise the "too much lead" would also cause imbalance and then have to be compensated again.

When the rim is damaged or bent, there is sometimes no other option to apply lead in a number of places, because there is then imbalance in various places. A bent rim can in most cases be unbalanced up to 0 grams, but this will always cause a vibration in the car due to the height stroke that the wheel then makes.

Amount of imbalance:

A normal wheel usually has between 10 and 30 grams of imbalance. It occasionally happens that the wheel has no imbalance at all, because the tire is mounted on exactly the right position of the rim by accident. The deviations in the tire precisely compensate for the deviations in the rim. This point is sought in modern balancing machines.

When a wheel has more than 50 grams of imbalance, it is wise to turn the tire relative to the rim. When the rim itself also has a deviation that is exactly on the same point as the tire, the imbalance is reinforced. By twisting the belt, the imbalance can be lifted against each other. It is best to turn the belt half a turn the first time. If it doesn't improve, or even worse, turn the tire a quarter of a turn. If the imbalance is still too high, the tire can be turned another half a turn (now the tire has had 4 different positions on the rim). Too much imbalance in all 4 positions can lead to doubts about the quality of the tire or rim. A deviation on the rim can usually be seen when turning; the oscillation is quickly recognizable.

Lead:

Actually, the 'lead' used to unbalance the wheels is no longer real lead, but zinc. This is much more environmentally friendly and cheaper. Despite that, it is still called lead (or balancing weight).

There are 2 types of lead; percussion lead and adhesive lead. Percussion lead is always used on steel rims. The lead is then struck on the rim flange.

Alloy wheels also often have a special rim flange on the inside that can be used to store lead. You normally do not see this and is cheaper than adhesive lead. Percussion lead for alloy rims is somewhat different than for steel rims; the hook on the lead is wider and larger than that of a steel rim.

Each weight has its own weight. The higher the weight, the larger the size. The leads have a weight of 5 to 60 grams, in increments of 5.

Adhesive lead is always used on alloy wheels. The lead is pasted into the rim. Adhesive lead is sometimes by weight (from 5 grams to 60 grams in steps of 5) or they are strips that have to be torn to size. (1 block is 5 grams, so for 20 grams you need 4 blocks).