Subjects:

- measuring taper

- Measuring ovality / roundness

- Grinding crankshaft

Measuring Taper:

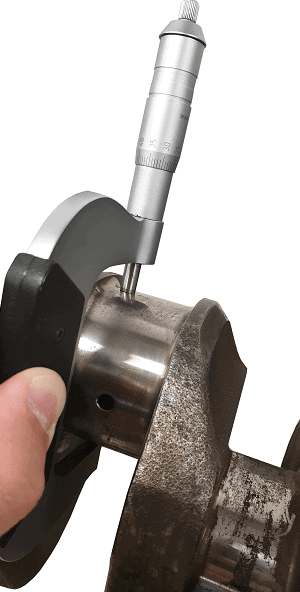

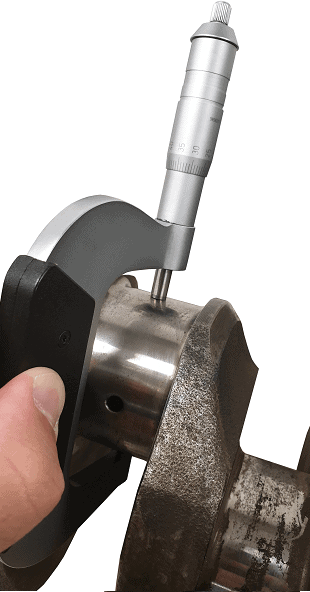

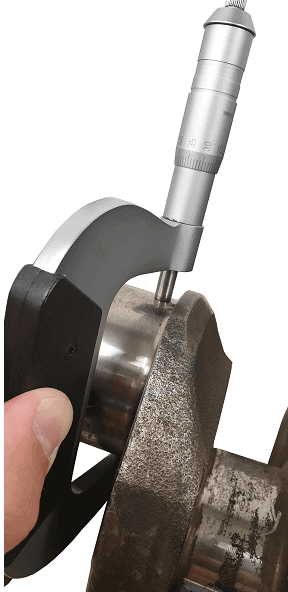

The crankshaft bearing journals can become tapered due to excessive wear. With a disassembled crankshaft, we can perform measurements on the main bearing journals and connecting rod bearing journals. Measurements can only be made with a micrometer for the sake of accuracy.

With three measurements, the taper of bearing journals on a crankshaft can be measured. The diameters of the bearing journals should be nearly equal in all three measurements. If a lower value occurs in one of the measurements (eg between the measurements on the left and right the diameter is 0,2 mm) then the crank pin has become tapered as a result of wear.

The three images below show the measurements where the taper is determined. The micrometer cannot be read in this camera angle.

Measuring ovality / roundness:

The roundness of main bearing and connecting rod bearing journals is very precise. The bearing shells constantly slide over this – by means of an oil film. When a crank pin is no longer completely round (in other words: oval) as a result of wear, an axial bearing play that is too large or friction can be caused by too small a play. In both cases, consequential damage will occur in the long run.

The ovality of a bearing journal can be measured with two measurements. The measurements are taken 90 degrees to each other at approximately the center of the tap. If both measurements give the same result, the respective crank pin is not oval. An out-of-roundness of 0,02 mm is already outside the tolerances: it is then necessary to grind the crankshaft. Always refer to the manufacturer's prescribed measurement values for these measurements.

Grinding crankshaft:

When measuring the taper and ovality of the crankshaft main bearing and connecting rod bearing journals, the crankshaft may be rejected as a result of the measurement results. In most cases, it is possible to have the crankshaft sharpened by an overhaul specialist and, if necessary, to be repaired. to balance. Since material has been removed during grinding, oversized bearing shells must be fitted. The two images below show the grinding process of a main bearing journal (left) and connecting rod bearing journal (right).