Subjects:

- General

- Purpose of the EGR system

- Operation

- High and Low Pressure EGR

- Disadvantages and possible malfunctions

- EGR cooler

General:

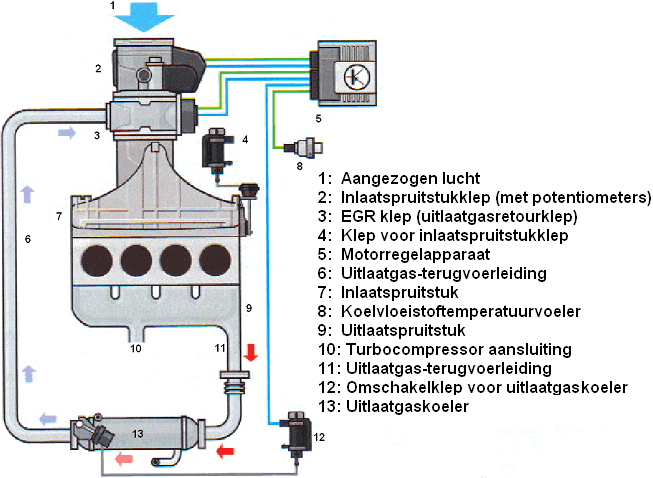

An EGR (Exhaust Gas Recirculation), also called “UGR” in Dutch (Exhaust Gas Recirculation) by some brands, has the task of returning part of the exhaust gases to the engine. The EGR valve is used on both petrol and diesel engines. The EGR is mounted on the exhaust side of the engine block.

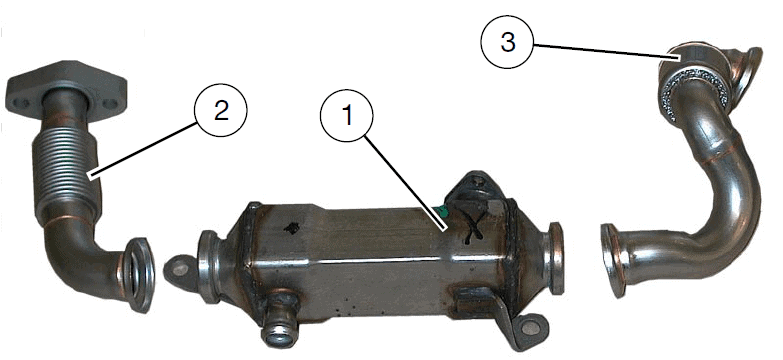

A thick metal pipe runs from the exhaust manifold to the EGR cooler. This cools the hot exhaust gases (effect of a heat exchanger). From the EGR cooler, the exhaust gas goes to the EGR valve, which mixes the exhaust gases with the supplied air. EGR can be output as a high pressure (short route) or a low pressure (long route). Both systems have their own advantages and disadvantages. This is described in the High and Low Pressure EGR chapter (later on this page).

The EGR valve and lines can be mounted in different places, but the exhaust gas is always drained as close to the exhaust manifold as possible. The image below shows the locations where the components of the EGR are mounted on the engine block.

Because the EGR valve has to be opened or completely closed in several positions, a stepper motor to operate the valve.

Purpose of the EGR system:

By adding small amounts of exhaust gas to the fresh air in the engine's intake, the oxygen content for combustion is reduced. A lower oxygen ratio results in a 'less good' combustion. The combustion rate and the combustion temperature decrease as a result. The lower temperature of the combustion gases reduces the nitrogen oxides (NOx) content. This makes the exhaust gases cleaner, which benefits the environmental requirements.

On older engines, the EGR valve is closed when the engine is cold. On the new engines, the valve is also open when the engine is cold, so that the warm exhaust gases help to warm up the engine. The EGR is inoperative when accelerating, decelerating and idling. At partial load, the operation is fully utilized.

Operation:

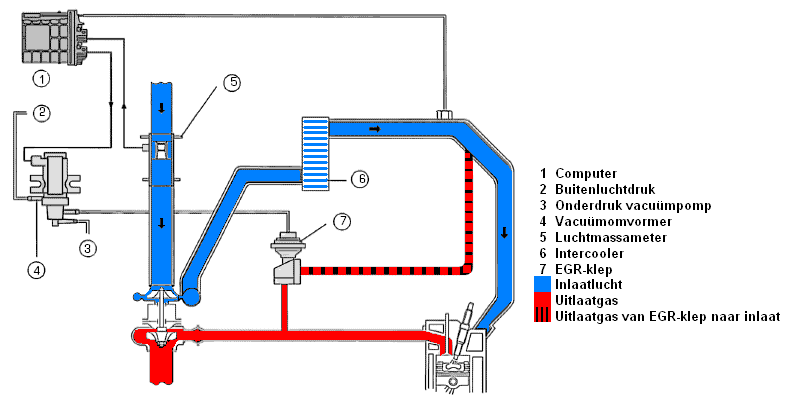

The computer controls the amount of exhaust that may be returned to the engine based on the following data:

- The engine load (the EGR only works at part load; at full load, the valve is closed).

- The engine speed (when the speed is too low or too high, the valve is closed).

- The intake air temperature.

With this data, the computer controls the solenoid valve with a specific duty cycle. If the difference is minimal, the vacuum transducer is controlled so that the EGR valve is not activated. In this rest position, the solenoid valve transmits the outside air pressure to the EGR valve. However, if the amount of air drawn in is greater than the required amount of air, the solenoid valve is actuated in such a way that the vacuum of the vacuum pump is also applied to the EGR valve. The vacuum from the vacuum pump to the EGR valve is thus regulated by means of the solenoid valve. As a result, the EGR valve is opened so far that the difference between the required and the intake air is always minimal.

High and Low Pressure EGR:

The exhaust gas recirculation system can be divided into two systems, namely the high pressure EGR and the low pressure EGR. The difference is where the exhaust gases are tapped from the exhaust. The operation, advantages and disadvantages of both systems are described below.

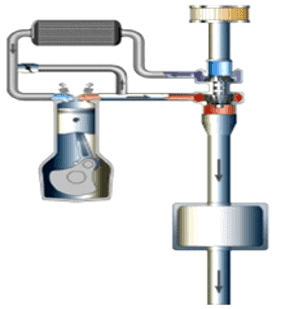

High Pressure EGR (short route):

The exhaust gases are already returned to the engine before the turbo. There is an EGR line between the exhaust manifold and the turbo. Often there is a cooler on this line to bring the exhaust gas temperature down. The EGR valve is located at the end of this line. When the EGR valve opens, the exhaust gases in the line mix with the intake air that is fed from the intercooler to the engine's intake.

Advantages of the high pressure EGR:

- EGR can be adjusted very quickly to the dynamic engine condition.

- At a cold start, the EGR will help to raise the temperature in the combustion chamber as quickly as possible (standard for diesel engines of the EURO III generation and later).

Cons:

- Contamination in the intake path due to soot formation.

- Exhaust gas needs to be cooled more than when a low pressure EGR is used.

- Exhaust gas flow is not fully utilized to drive the turbo turbine; part of the gas is already drained before the turbo.

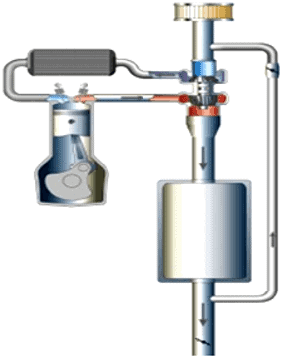

Low Pressure EGR (Long Route):

The exhaust gases are only returned to the engine inlet after the diesel particulate filter. Usually the outlet of the EGR valve is connected to the input of the compressor (as shown in the picture), but sometimes it is connected between the intercooler and the intake manifold. The disadvantage is that the recycled exhaust gas has too low a pressure and velocity. To solve this, an extra valve is installed in the exhaust (after the EGR branch). The moment this extra valve closes, the pressure between the turbo and the valve increases. The exhaust gases will be carried through the branch to the EGR valve due to the increased pressure.

Advantages of the low pressure EGR:

- All the exhaust gas has already been used in the turbine of the turbo

- Exhaust gas temperature is low (without using an EGR cooler) with regard to the high pressure EGR.

- EGR gas is cleaner because, among other things, the particulate filter has already carried out the exhaust gas after-treatment, so less engine pollution due to soot formation.

Cons:

- Adding exhaust gas to the intake air (according to the dynamic engine condition) is slower, because the EGR has to travel a longer distance.

- The EGR valve is further from the intake valves.

Disadvantages and possible malfunctions:

The EGR valve does not improve the performance of the engine. Using the EGR valve can reduce performance and increase fuel consumption. The internal pollution will also increase strongly (see image). The dirt sticks to everything and in this way also pollutes the intake manifold and the intake valves of the engine. Especially with a calm driving style, these contaminants remain in the engine.

The only advantage of the EGR is that the exhaust gases are cleaner; NOx emissions decrease. With the older diesel engines, the EGR valves could easily be closed by means of a closing plate. The manufacturers of the new cars use sensors and other methods to ensure that it is no longer possible to shut off or deceive the EGR, because the pressures are measured at various places in the pipeline. That is why a software adjustment will have to be made in the engine management system for newer cars. This is often part of the new software for chip tuning.

It is possible that the EGR valve inadvertently remains open while it is not being actuated. Too much exhaust gases are then fed to the engine. With a reading device we can recognize this by:

- a (permanently) high inlet air temperature as a result of the exhaust gases (see the page about the temperature sensors);

- a value of the air mass meter too low: a large percentage of the incoming air consists of air coming from the EGR, instead of from the air filter.

EGR cooler:

The temperature of the exhaust gases is approximately 300 degrees in part load (at constant temperature on the highway) and more than 700 degrees at full load. However, the colder the air supplied to the intake, the better the engine performs. Cold air contains more oxygen. Warm air is more expanded and therefore contains less oxygen. Nevertheless, warm exhaust gases are fed back into the engine.

There is often an EGR cooler between the EGR valve and the intake of the engine. It works as a heat exchanger. Coolant flows through the EGR cooler (in fixed channels, so it does not come into direct contact with the exhaust gases). The coolant absorbs the heat from the exhaust gases. The coolant then becomes warmer and the exhaust gases cool down. The EGR cooler lowers the temperature as far as possible, preferably at 100 degrees.

More information about this heat exchange technique can be found in the chapter heat exchanger.

In addition to the EGR, petrol engines also have a secondary air pump used to after-treat the exhaust gases and is used in diesel engines to Selective Catalytic Reduction SCR catalyst with AdBluedosing system applied.